Gelcoat application on composite PET surfaces provides a smooth, durable finish that enhances corrosion resistance and aesthetic appeal. Peel ply application, by contrast, creates a textured surface that improves adhesion for subsequent bonding or painting processes without additional surface preparation. Selecting gelcoat ensures a protective top layer, while peel ply optimizes the composite's readiness for further manufacturing steps.

Table of Comparison

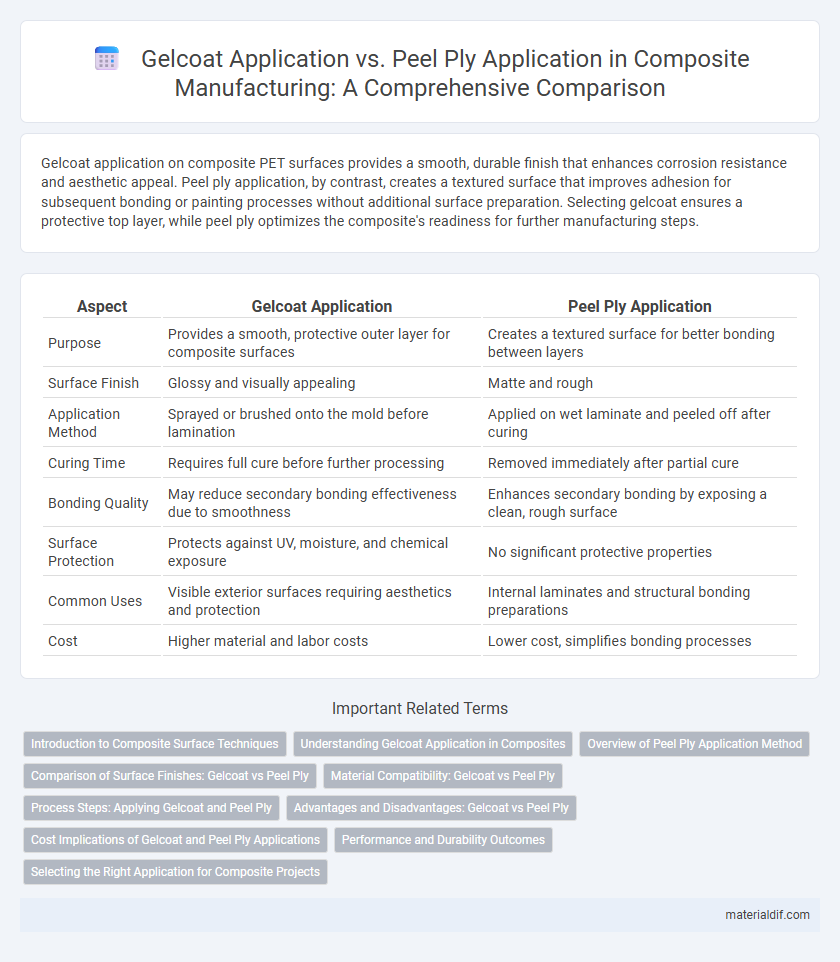

| Aspect | Gelcoat Application | Peel Ply Application |

|---|---|---|

| Purpose | Provides a smooth, protective outer layer for composite surfaces | Creates a textured surface for better bonding between layers |

| Surface Finish | Glossy and visually appealing | Matte and rough |

| Application Method | Sprayed or brushed onto the mold before lamination | Applied on wet laminate and peeled off after curing |

| Curing Time | Requires full cure before further processing | Removed immediately after partial cure |

| Bonding Quality | May reduce secondary bonding effectiveness due to smoothness | Enhances secondary bonding by exposing a clean, rough surface |

| Surface Protection | Protects against UV, moisture, and chemical exposure | No significant protective properties |

| Common Uses | Visible exterior surfaces requiring aesthetics and protection | Internal laminates and structural bonding preparations |

| Cost | Higher material and labor costs | Lower cost, simplifies bonding processes |

Introduction to Composite Surface Techniques

Gelcoat application creates a smooth, durable surface finish that enhances weather resistance and aesthetic appeal in composite parts, making it essential for marine and automotive industries. Peel ply application improves surface adhesion by providing a clean, textured substrate for secondary bonding or painting, which is critical in structural composite fabrication. Understanding these surface techniques ensures optimal performance and longevity of composite materials in various engineering applications.

Understanding Gelcoat Application in Composites

Gelcoat application in composites involves the precise layering of a pigmented resin to create a smooth, durable surface that enhances aesthetics and protects underlying fiberglass structures from moisture and UV damage. This topcoat is typically applied using spraying or brushing techniques, ensuring uniform coverage and preventing defects such as blisters or pinholes, which can compromise composite integrity. Unlike peel ply application, which focuses on surface preparation and bonding, gelcoat serves as both a protective barrier and a finish, making it essential for marine, automotive, and aerospace composite manufacturing.

Overview of Peel Ply Application Method

Peel ply application method involves placing a layer of porous fabric on the composite surface before curing, which creates a textured finish ideal for secondary bonding. This technique enhances surface cleanliness and adhesion without additional abrasion or chemical treatments, improving composite part quality. Peel ply removal after curing exposes a uniformly rough surface, facilitating superior bonding strength in subsequent manufacturing steps.

Comparison of Surface Finishes: Gelcoat vs Peel Ply

Gelcoat provides a smooth, glossy surface finish that enhances aesthetic appeal and offers durable protection against environmental factors. Peel ply creates a rough, textured surface optimized for secondary bonding and coating adhesion but requires additional preparation for a finished appearance. The choice between gelcoat and peel ply depends on whether a high-quality surface finish or improved bonding properties are the primary focus for the composite application.

Material Compatibility: Gelcoat vs Peel Ply

Gelcoat application requires surface compatibility with resin-rich layers to ensure smooth curing and optimal adhesion, typically bonding well with polyester and vinyl ester resins. Peel ply application involves using a fabric layer compatible with the composite resin system, such as epoxy or polyester, to create a clean, textured surface ideal for secondary bonding or coatings. Material compatibility between gelcoat and peel ply influences surface finish quality, bonding strength, and overall composite durability in marine and aerospace industries.

Process Steps: Applying Gelcoat and Peel Ply

Applying gelcoat involves spraying or brushing a resin-based coating onto the mold surface to create a smooth, protective finish that enhances durability and aesthetics. In contrast, peel ply application consists of laying a specialized fabric over the composite layup before curing, which facilitates clean removal and surface preparation for subsequent bonding or painting. The gelcoat process requires precise thickness control and curing time, while peel ply application emphasizes proper placement and secure adhesion to avoid defects.

Advantages and Disadvantages: Gelcoat vs Peel Ply

Gelcoat application provides a smooth, high-performance surface finish ideal for aesthetics and corrosion resistance but requires curing time and can be prone to cracking under stress. Peel ply application enhances surface preparation for bonding by creating a textured finish, improving adhesion without contamination, though it may leave residue requiring further cleaning. Gelcoat offers superior environmental protection, whereas peel ply excels in ensuring mechanical interlayer strength and process efficiency.

Cost Implications of Gelcoat and Peel Ply Applications

Gelcoat application typically incurs higher upfront material and labor costs due to the need for specialized surface preparation and curing processes, while peel ply application offers cost savings by simplifying post-lamination finishing and reducing secondary operations. The reuse potential and less stringent handling requirements of peel ply reduce waste and labor expenses, making it a cost-effective choice in high-volume composite manufacturing. However, gelcoat provides superior surface protection and aesthetics, which can justify its higher expense in applications demanding premium finish quality.

Performance and Durability Outcomes

Gelcoat application provides a smooth, high-gloss surface with superior UV resistance, enhancing the composite's aesthetic appeal and long-term durability in outdoor environments. Peel ply application ensures consistent surface texture for optimal secondary bonding but lacks the protective, weather-resistant properties of gelcoat. Performance-wise, gelcoat extends the lifespan of composites exposed to harsh conditions, while peel ply primarily supports manufacturing quality without significantly improving durability.

Selecting the Right Application for Composite Projects

Gelcoat application provides a smooth, durable surface finishing essential for protecting composite structures from environmental damage and enhancing aesthetic appeal, making it ideal for visible exterior parts. Peel ply application ensures a clean, contaminant-free surface ready for secondary bonding or coating, crucial for structural integrity and adhesion in complex assemblies. Selecting the right method depends on the end-use requirements: gelcoat for surface protection and appearance, peel ply for optimal bonding and lamination quality in composite projects.

Gelcoat Application vs Peel Ply Application Infographic

materialdif.com

materialdif.com