Resin Transfer Molding (RTM) offers superior precision and consistency compared to Hand Lay-Up, enabling better fiber wet-out and reduced void content in composite parts. RTM is ideal for high-volume production with complex geometries, providing enhanced mechanical properties and surface finish. Hand Lay-Up remains cost-effective for simple, low-volume applications but often results in higher labor intensity and less repeatability.

Table of Comparison

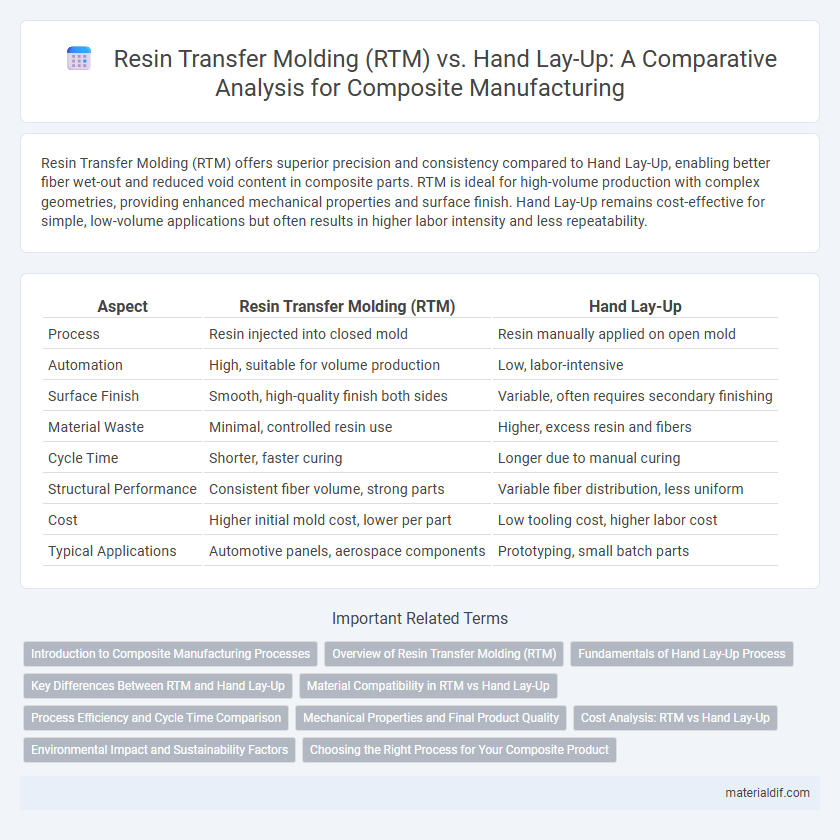

| Aspect | Resin Transfer Molding (RTM) | Hand Lay-Up |

|---|---|---|

| Process | Resin injected into closed mold | Resin manually applied on open mold |

| Automation | High, suitable for volume production | Low, labor-intensive |

| Surface Finish | Smooth, high-quality finish both sides | Variable, often requires secondary finishing |

| Material Waste | Minimal, controlled resin use | Higher, excess resin and fibers |

| Cycle Time | Shorter, faster curing | Longer due to manual curing |

| Structural Performance | Consistent fiber volume, strong parts | Variable fiber distribution, less uniform |

| Cost | Higher initial mold cost, lower per part | Low tooling cost, higher labor cost |

| Typical Applications | Automotive panels, aerospace components | Prototyping, small batch parts |

Introduction to Composite Manufacturing Processes

Resin Transfer Molding (RTM) and Hand Lay-Up represent two pivotal composite manufacturing processes distinguished by automation and quality control levels. RTM involves injecting resin into a closed mold containing dry fiber reinforcements, enabling precise resin distribution and superior surface finish, making it ideal for complex geometries and high-volume production. Conversely, Hand Lay-Up is a manual method where layers of resin and reinforcement are applied open to the air, offering flexibility and lower initial costs but resulting in less consistent mechanical properties and longer production times.

Overview of Resin Transfer Molding (RTM)

Resin Transfer Molding (RTM) is a closed-mold composite manufacturing process where resin is injected into a sealed mold containing dry fiber reinforcements, ensuring consistent fiber wet-out and high-quality structural parts. RTM offers superior surface finish and dimensional accuracy compared to the open-mold Hand Lay-Up process, reducing waste and emissions. This method is widely used in producing complex aerospace, automotive, and marine components with high strength-to-weight ratios and improved repeatability.

Fundamentals of Hand Lay-Up Process

The Hand Lay-Up process involves manually placing reinforcement fibers into a mold followed by impregnating them with resin, relying on skilled labor for precise layering. This open molding technique allows for flexibility in part size and complexity but typically results in lower fiber volume fractions compared to Resin Transfer Molding (RTM). The fundamental steps include mold preparation, fiber positioning, resin application, curing, and demolding, with careful control over resin distribution critical to achieving desired mechanical properties.

Key Differences Between RTM and Hand Lay-Up

Resin Transfer Molding (RTM) involves injecting resin into a closed mold, resulting in higher precision, better surface finish, and improved fiber-to-resin ratio compared to Hand Lay-Up, which is an open-mold process relying on manual application of resin and reinforcement. RTM offers faster cycle times and greater automation potential, while Hand Lay-Up is labor-intensive with significant operator variability and longer curing periods. The controlled environment of RTM enhances mechanical properties and reduces void content, making it superior for high-performance composite manufacturing.

Material Compatibility in RTM vs Hand Lay-Up

Resin Transfer Molding (RTM) offers enhanced material compatibility by efficiently infusing resin into complex fiber preforms, ensuring uniform resin distribution and superior fiber wet-out compared to Hand Lay-Up, which relies on manual resin application and risks air entrapment. RTM supports a wider range of advanced thermosetting resins and high-performance fibers, optimizing mechanical properties and reducing void content. In contrast, Hand Lay-Up is typically limited to simpler resin systems and may not achieve the same level of consistency or structural integrity in composite materials.

Process Efficiency and Cycle Time Comparison

Resin Transfer Molding (RTM) offers superior process efficiency compared to Hand Lay-Up by automating resin infusion, reducing manual labor and minimizing material waste. RTM significantly shortens cycle time, enabling the production of complex composite parts within minutes, whereas Hand Lay-Up typically requires several hours due to manual layering and curing stages. The controlled environment of RTM ensures consistent part quality and repeatability, outperforming the variability inherent in Hand Lay-Up processes.

Mechanical Properties and Final Product Quality

Resin Transfer Molding (RTM) offers superior mechanical properties compared to Hand Lay-Up due to its controlled resin injection, resulting in higher fiber volume fraction and reduced void content, which enhances strength and stiffness. RTM produces composite parts with consistent quality, uniform thickness, and complex geometries, whereas Hand Lay-Up often results in variable resin distribution and potential defects that compromise final product integrity. The automated nature of RTM ensures repeatability and superior surface finish, critical for high-performance applications requiring precise mechanical performance.

Cost Analysis: RTM vs Hand Lay-Up

Resin Transfer Molding (RTM) typically incurs higher initial tooling and equipment costs compared to Hand Lay-Up, which relies on manual labor and minimal capital investment. Despite the upfront expenses, RTM offers lower labor costs and reduced material waste, resulting in a more cost-effective process for high-volume composite production. Hand Lay-Up remains economical for low-volume or prototype manufacturing but faces higher labor intensity and inconsistent quality, increasing overall operational costs over time.

Environmental Impact and Sustainability Factors

Resin Transfer Molding (RTM) generates less volatile organic compounds (VOCs) compared to Hand Lay-Up, enhancing workplace air quality and reducing environmental pollution. RTM's closed-mold process minimizes resin waste and supports the use of bio-based resins, advancing sustainability in composite manufacturing. In contrast, Hand Lay-Up often results in higher material scrap rates and energy consumption, contributing to a larger carbon footprint.

Choosing the Right Process for Your Composite Product

Resin Transfer Molding (RTM) offers precise control over resin flow and produces high-strength composite parts with excellent surface finish, making it ideal for complex geometries and medium to high production volumes. Hand Lay-Up remains a cost-effective method suited for low-volume, large-scale components where flexibility and simplicity are prioritized over automation and repeatability. Selecting between RTM and Hand Lay-Up depends on factors such as production volume, desired part quality, complexity, and labor availability.

Resin Transfer Molding (RTM) vs Hand Lay-Up Infographic

materialdif.com

materialdif.com