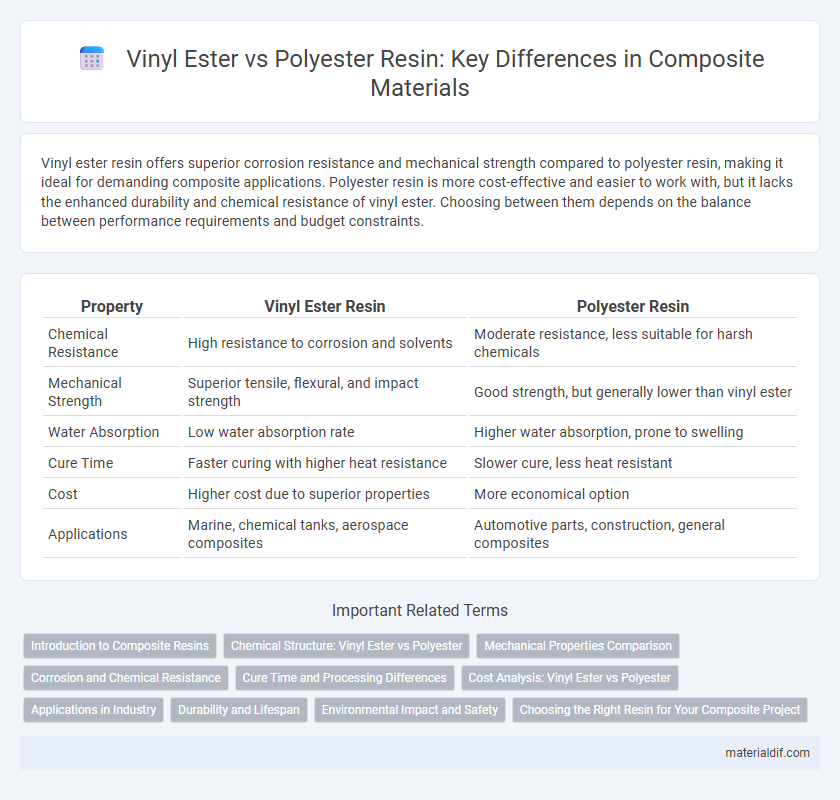

Vinyl ester resin offers superior corrosion resistance and mechanical strength compared to polyester resin, making it ideal for demanding composite applications. Polyester resin is more cost-effective and easier to work with, but it lacks the enhanced durability and chemical resistance of vinyl ester. Choosing between them depends on the balance between performance requirements and budget constraints.

Table of Comparison

| Property | Vinyl Ester Resin | Polyester Resin |

|---|---|---|

| Chemical Resistance | High resistance to corrosion and solvents | Moderate resistance, less suitable for harsh chemicals |

| Mechanical Strength | Superior tensile, flexural, and impact strength | Good strength, but generally lower than vinyl ester |

| Water Absorption | Low water absorption rate | Higher water absorption, prone to swelling |

| Cure Time | Faster curing with higher heat resistance | Slower cure, less heat resistant |

| Cost | Higher cost due to superior properties | More economical option |

| Applications | Marine, chemical tanks, aerospace composites | Automotive parts, construction, general composites |

Introduction to Composite Resins

Vinyl ester resin offers superior chemical resistance and mechanical strength compared to polyester resin, making it ideal for high-performance composite applications. Polyester resin is more cost-effective and widely used in general-purpose composite manufacturing due to its ease of processing and fast curing time. Both resins serve crucial roles in composite fabrication, with vinyl ester preferred for durability and polyester for affordability.

Chemical Structure: Vinyl Ester vs Polyester

Vinyl ester resins possess a chemical structure characterized by ester groups formed from epoxy resins and acrylic or methacrylic acids, providing enhanced corrosion resistance and mechanical strength compared to polyester resins. Polyester resins feature a backbone of repeating polyester units derived from the polycondensation of dibasic acids and glycols, resulting in lower chemical resistance and moderate mechanical properties. The distinct chemical structure of vinyl ester resins leads to better adhesion and reduced water absorption, making them preferable for harsh environments.

Mechanical Properties Comparison

Vinyl ester resin exhibits superior mechanical properties compared to polyester resin, including higher tensile strength, better impact resistance, and enhanced elongation at break, making it suitable for demanding structural applications. Polyester resin tends to have lower mechanical strength and brittleness issues, which limit its use in high-performance composites. The improved performance of vinyl ester is attributed to its chemical structure, providing better adhesion and greater resistance to crack propagation under stress.

Corrosion and Chemical Resistance

Vinyl ester resin offers superior corrosion and chemical resistance compared to polyester resin, making it ideal for harsh industrial environments and exposure to aggressive chemicals. Its molecular structure provides enhanced resistance to acids, alkalis, and solvents, reducing degradation and extending the lifespan of composite materials. Polyester resin, while cost-effective, is more susceptible to chemical attack and moisture absorption, limiting its use in highly corrosive applications.

Cure Time and Processing Differences

Vinyl ester resin cures faster than polyester resin, typically completing within 20 to 30 minutes compared to polyester's 30 to 45 minutes, making it more efficient for time-sensitive applications. Processing differences include vinyl ester's superior chemical resistance and heat tolerance, which often require precise temperature control and catalyst dosing during curing. Polyester resin offers easier handling and lower material cost but demands longer curing times and sometimes results in higher shrinkage and brittleness.

Cost Analysis: Vinyl Ester vs Polyester

Vinyl ester resin typically incurs higher initial costs than polyester resin due to its superior chemical resistance and mechanical properties, which justify the investment in applications demanding durability. Polyester resin offers a cost-effective solution for less demanding environments, with lower material prices and faster curing times contributing to reduced overall production expenses. Evaluating long-term maintenance and lifespan reveals that vinyl ester's enhanced resistance to corrosion and fatigue can lead to lower lifecycle costs despite its upfront price premium.

Applications in Industry

Vinyl ester resin offers superior chemical resistance and mechanical strength compared to polyester resin, making it ideal for demanding applications in chemical processing, marine, and corrosion-resistant coatings. Polyester resin is widely used in automotive, construction, and general fiberglass fabrication due to its cost-effectiveness and ease of use. Industries requiring high durability and temperature resistance often prefer vinyl ester resin for critical components like storage tanks, pipes, and marine vessels.

Durability and Lifespan

Vinyl ester resin exhibits superior durability compared to polyester resin due to its enhanced chemical resistance and higher tensile strength, making it ideal for harsh environments. Its lifespan significantly exceeds polyester resin, often lasting 5 to 10 years longer in corrosive or marine applications. Polyester resin tends to degrade faster under UV exposure and moisture, limiting its long-term structural performance.

Environmental Impact and Safety

Vinyl ester resin demonstrates superior chemical resistance and lower volatile organic compound (VOC) emissions compared to polyester resin, reducing environmental pollution during manufacturing and application. Polyester resin typically emits higher levels of styrene, a hazardous air pollutant linked to respiratory issues and environmental harm, posing greater safety risks for workers and nearby populations. Vinyl ester's enhanced durability and resistance to degradation also contribute to longer-lasting composites, minimizing waste and environmental impact over the product lifecycle.

Choosing the Right Resin for Your Composite Project

Vinyl ester resin offers superior corrosion resistance, higher tensile strength, and better impact durability compared to polyester resin, making it ideal for demanding composite applications exposed to harsh chemicals or high stress. Polyester resin is more cost-effective and easier to work with, suitable for non-structural components and projects with budget constraints. Selecting the right resin depends on assessing environmental exposure, mechanical requirements, and cost considerations specific to the composite project.

Vinyl Ester vs Polyester Resin Infographic

materialdif.com

materialdif.com