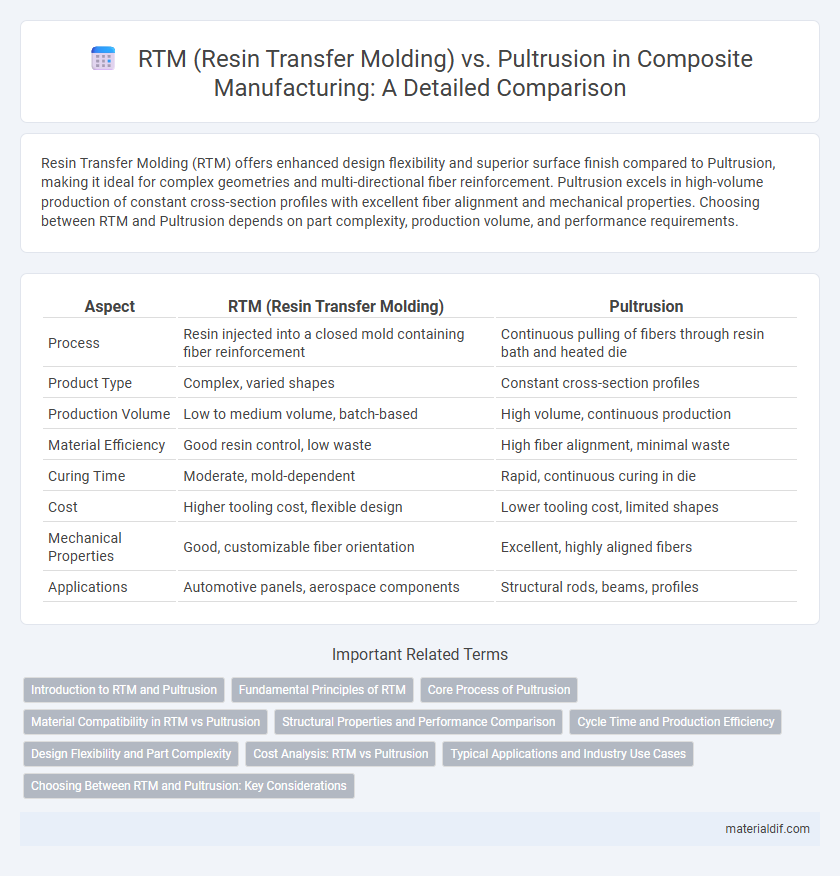

Resin Transfer Molding (RTM) offers enhanced design flexibility and superior surface finish compared to Pultrusion, making it ideal for complex geometries and multi-directional fiber reinforcement. Pultrusion excels in high-volume production of constant cross-section profiles with excellent fiber alignment and mechanical properties. Choosing between RTM and Pultrusion depends on part complexity, production volume, and performance requirements.

Table of Comparison

| Aspect | RTM (Resin Transfer Molding) | Pultrusion |

|---|---|---|

| Process | Resin injected into a closed mold containing fiber reinforcement | Continuous pulling of fibers through resin bath and heated die |

| Product Type | Complex, varied shapes | Constant cross-section profiles |

| Production Volume | Low to medium volume, batch-based | High volume, continuous production |

| Material Efficiency | Good resin control, low waste | High fiber alignment, minimal waste |

| Curing Time | Moderate, mold-dependent | Rapid, continuous curing in die |

| Cost | Higher tooling cost, flexible design | Lower tooling cost, limited shapes |

| Mechanical Properties | Good, customizable fiber orientation | Excellent, highly aligned fibers |

| Applications | Automotive panels, aerospace components | Structural rods, beams, profiles |

Introduction to RTM and Pultrusion

Resin Transfer Molding (RTM) is a closed-mold process where resin is injected under pressure into a mold containing a fiber preform, allowing precise control over fiber-to-resin ratios and complex shapes. Pultrusion is a continuous manufacturing technique that pulls fibers through a resin bath and heated die, producing constant cross-section composite profiles with high fiber alignment and strength. RTM offers greater design flexibility and is ideal for complex geometries, while pultrusion excels in high-volume production of uniform structural components.

Fundamental Principles of RTM

Resin Transfer Molding (RTM) involves injecting resin into a closed mold containing dry fiber reinforcements, enabling precise control over fiber orientation and resin distribution to achieve high-quality composite parts. Unlike Pultrusion, which continuously pulls fibers through a resin bath and heated die for constant profiles, RTM offers flexibility in complex geometries and thickness variations. The fundamental principle of RTM centers on resin flow dynamics and pressure-driven impregnation to ensure complete wet-out and minimize void content within the composite structure.

Core Process of Pultrusion

Pultrusion is a continuous manufacturing process that pulls fibers through a resin bath and then through a heated steel die to cure and shape composite profiles, offering high-volume production of consistent cross-sections. Unlike RTM (Resin Transfer Molding), which involves injecting resin into a closed mold with fiber preforms, pultrusion emphasizes continuous fiber alignment and rapid curing for strong, lightweight composite components. Core to pultrusion is its ability to maintain fiber orientation and produce complex shapes with excellent mechanical properties and minimal waste.

Material Compatibility in RTM vs Pultrusion

RTM (Resin Transfer Molding) accommodates a wider range of thermosetting resins such as epoxy, polyester, and vinylester, making it highly versatile for complex composite parts with varying material requirements. Pultrusion is typically limited to thermosetting resins that can cure rapidly under heat, with polyester and vinylester resins being the most common due to their ability to maintain resin flow during continuous production. The superior material compatibility of RTM enables engineers to select optimized resin and fiber combinations tailored for mechanical strength, chemical resistance, and thermal performance, whereas pultrusion sacrifices some material variety for cost-effective mass production of uniform profiles.

Structural Properties and Performance Comparison

Resin Transfer Molding (RTM) offers superior structural properties with enhanced fiber volume fraction and complex geometry capabilities, resulting in higher strength-to-weight ratios compared to Pultrusion. Pultrusion provides consistent cross-sectional profiles and excellent longitudinal mechanical properties due to continuous fiber alignment, optimizing tensile and flexural strength along the length. Performance analysis highlights RTM's advantage in impact resistance and design flexibility, whereas Pultrusion excels in high-volume production efficiency and uniformity for load-bearing applications.

Cycle Time and Production Efficiency

RTM (Resin Transfer Molding) offers a cycle time typically ranging from 10 to 30 minutes, enabling moderate production efficiency for complex, high-performance composite parts. Pultrusion excels with cycle times as low as a few seconds per linear foot, delivering superior production efficiency for continuous profiles with consistent cross-sections. The choice between RTM and pultrusion hinges on balancing the need for rapid output against part complexity and quality requirements.

Design Flexibility and Part Complexity

Resin Transfer Molding (RTM) offers superior design flexibility compared to Pultrusion, enabling the production of complex geometries and varying cross-sections in composite parts. RTM allows for intricate features and integrated components due to its closed-mold process, whereas Pultrusion is limited to constant cross-sectional profiles ideal for simple, linear parts. The ability of RTM to accommodate undercuts, varying thicknesses, and complex fiber orientations makes it preferable for high-performance, customized composite structures.

Cost Analysis: RTM vs Pultrusion

RTM (Resin Transfer Molding) generally incurs higher upfront tooling and mold costs compared to Pultrusion, which benefits from continuous production and lower initial investment. However, RTM offers greater design flexibility and can produce complex shapes with better surface finish, whereas Pultrusion is more cost-effective for high-volume, uniform cross-section parts due to reduced cycle times and minimal labor input. Overall, the cost efficiency of RTM versus Pultrusion depends on production volume, part complexity, and material requirements, making RTM suited for lower volumes with intricate geometries and Pultrusion optimal for mass-produced, straight profiles.

Typical Applications and Industry Use Cases

RTM (Resin Transfer Molding) is extensively used in aerospace, automotive, and marine industries for producing complex, high-strength composite parts like aircraft components and custom marine hulls, offering superior surface finish and design flexibility. Pultrusion excels in manufacturing continuous, uniform profiles such as structural beams, rods, and electrical insulators, widely applied in construction, infrastructure, and electrical sectors due to its high production speed and consistent quality. Both processes optimize composite material properties but cater to different application demands--RTM for intricate, precision parts and pultrusion for cost-effective, long-length structural elements.

Choosing Between RTM and Pultrusion: Key Considerations

Choosing between RTM and pultrusion involves evaluating factors such as design complexity, production volume, and mechanical property requirements. RTM excels in producing intricate, high-strength composite parts with excellent surface finish, making it ideal for low to medium production runs and complex geometries. Pultrusion offers cost-effective, high-volume manufacturing of consistent, straight profiles with superior fiber alignment, suitable for applications demanding continuous lengths and uniform cross-sections.

RTM (Resin Transfer Molding) vs Pultrusion Infographic

materialdif.com

materialdif.com