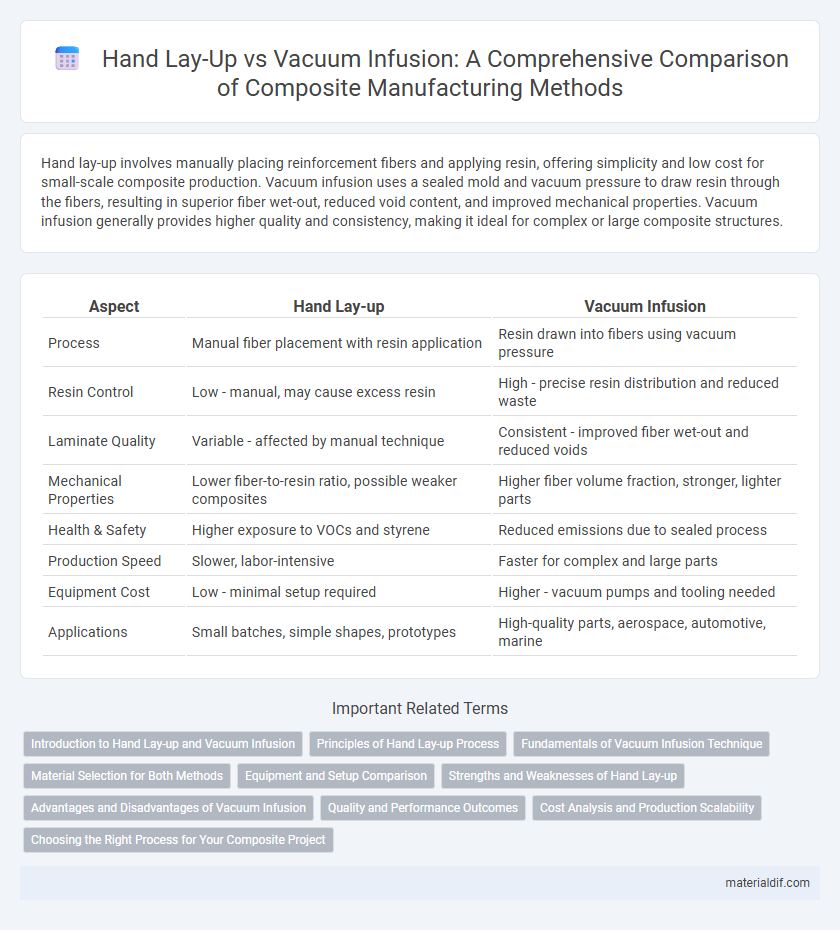

Hand lay-up involves manually placing reinforcement fibers and applying resin, offering simplicity and low cost for small-scale composite production. Vacuum infusion uses a sealed mold and vacuum pressure to draw resin through the fibers, resulting in superior fiber wet-out, reduced void content, and improved mechanical properties. Vacuum infusion generally provides higher quality and consistency, making it ideal for complex or large composite structures.

Table of Comparison

| Aspect | Hand Lay-up | Vacuum Infusion |

|---|---|---|

| Process | Manual fiber placement with resin application | Resin drawn into fibers using vacuum pressure |

| Resin Control | Low - manual, may cause excess resin | High - precise resin distribution and reduced waste |

| Laminate Quality | Variable - affected by manual technique | Consistent - improved fiber wet-out and reduced voids |

| Mechanical Properties | Lower fiber-to-resin ratio, possible weaker composites | Higher fiber volume fraction, stronger, lighter parts |

| Health & Safety | Higher exposure to VOCs and styrene | Reduced emissions due to sealed process |

| Production Speed | Slower, labor-intensive | Faster for complex and large parts |

| Equipment Cost | Low - minimal setup required | Higher - vacuum pumps and tooling needed |

| Applications | Small batches, simple shapes, prototypes | High-quality parts, aerospace, automotive, marine |

Introduction to Hand Lay-up and Vacuum Infusion

Hand lay-up is a traditional composite manufacturing method involving manually applying resin and reinforcement layers on a mold, offering simplicity and cost-effectiveness for low-volume production. Vacuum infusion enhances this process by using a vacuum to draw resin through the reinforcement, ensuring consistent resin distribution and reducing voids. This technique improves composite part strength and surface finish while minimizing emissions and worker exposure to hazardous chemicals.

Principles of Hand Lay-up Process

The hand lay-up process involves manually placing resin and reinforcement fibers onto a mold surface, allowing precise control over fiber orientation and thickness. This technique relies on open molding where resin is applied by brush or roller, facilitating straightforward fabrication of large or complex composite parts. Proper curing and air bubble removal ensure optimal structural integrity and surface finish in the final composite product.

Fundamentals of Vacuum Infusion Technique

Vacuum infusion technique involves placing dry composite fibers into a mold and then applying a vacuum to draw resin through the fibers, ensuring complete saturation and minimal void content. It offers superior fiber-to-resin ratio compared to hand lay-up, resulting in enhanced mechanical properties and reduced material waste. Control over resin flow and vacuum pressure allows for consistent laminate thickness and improved overall quality of composite parts.

Material Selection for Both Methods

Hand lay-up allows greater flexibility in material selection, accommodating a wide range of fiber reinforcements such as glass, carbon, and aramid fibers, combined with various thermosetting resins like polyester and epoxy. Vacuum infusion requires materials with specific permeability and resin viscosity properties to ensure complete wet-out and void-free laminates, favoring compatible dry fiber preforms and low-viscosity resins. Optimizing material choice directly affects mechanical performance, structural integrity, and production efficiency in both composite manufacturing methods.

Equipment and Setup Comparison

Hand Lay-up requires minimal equipment, including brushes, rollers, and release films, making it suitable for low-volume, simple composite parts. Vacuum Infusion involves a more complex setup with vacuum pumps, sealed bags, resin reservoirs, and peel plies to ensure thorough resin distribution and improved fiber-to-resin ratios. The equipment investment for Vacuum Infusion is higher but results in greater part consistency, reduced void content, and enhanced mechanical properties.

Strengths and Weaknesses of Hand Lay-up

Hand lay-up offers simplicity and low tooling costs, making it ideal for small-scale composite production and complex shapes. Its manual application can lead to inconsistent resin distribution and higher porosity, reducing structural strength compared to automated methods. Additionally, longer curing times and potential for air entrapment limit its suitability for high-performance or large-scale applications.

Advantages and Disadvantages of Vacuum Infusion

Vacuum infusion offers superior resin distribution and reduced void content, resulting in higher strength and lighter composite parts compared to hand lay-up. This process enhances worker safety by minimizing exposure to volatile organic compounds and reduces material waste through precise resin control. However, vacuum infusion requires more specialized equipment and longer setup times, potentially increasing initial costs and complexity.

Quality and Performance Outcomes

Hand lay-up composites often exhibit higher variability in resin distribution and fiber alignment, leading to inconsistent mechanical properties and increased void content. Vacuum infusion enhances quality by ensuring uniform resin flow, reducing voids, and improving fiber wet-out, which results in superior strength, stiffness, and overall structural integrity. Performance outcomes favor vacuum infusion for aerospace and automotive applications demanding high precision and repeatability.

Cost Analysis and Production Scalability

Hand lay-up offers low initial investment and flexible production for small batches, but labor-intensive processes increase variable costs and limit scalability. Vacuum infusion reduces labor expenses through automation, enabling higher production rates and consistent quality, yet requires significant upfront equipment costs and controlled environments. Cost analysis reveals vacuum infusion becomes more economical at scale, balancing material savings and throughput against capital expenditures.

Choosing the Right Process for Your Composite Project

Hand lay-up offers flexibility and low initial costs, making it suitable for small-scale or prototype composite projects with less strict quality requirements. Vacuum infusion provides superior fiber-to-resin ratios and consistent quality, ideal for high-performance applications demanding structural integrity and repeatability. Selecting the right process depends on project scale, complexity, and performance criteria, balancing cost, production speed, and mechanical properties.

Hand Lay-up vs Vacuum Infusion Infographic

materialdif.com

materialdif.com