Aramid fiber offers superior strength-to-weight ratio and enhanced impact resistance compared to glass fiber, making it ideal for high-performance composites in aerospace and defense applications. Glass fiber provides excellent cost-efficiency and good tensile strength, commonly used in automotive and construction industries where budget constraints are critical. Choosing between aramid and glass fiber depends on the specific requirements for durability, weight, and environmental resistance in composite fabrication.

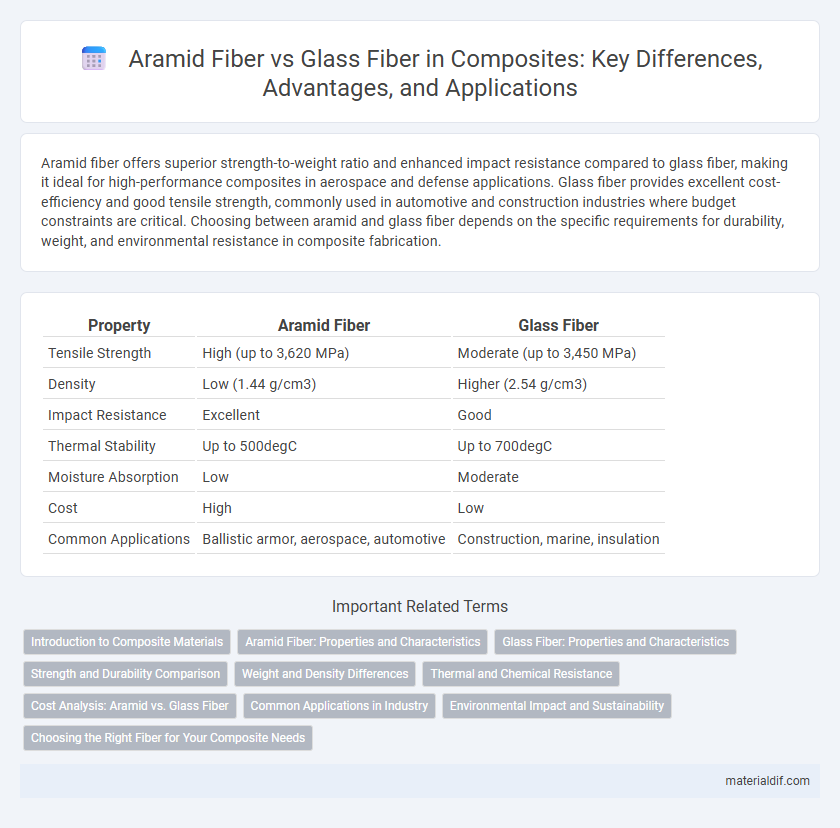

Table of Comparison

| Property | Aramid Fiber | Glass Fiber |

|---|---|---|

| Tensile Strength | High (up to 3,620 MPa) | Moderate (up to 3,450 MPa) |

| Density | Low (1.44 g/cm3) | Higher (2.54 g/cm3) |

| Impact Resistance | Excellent | Good |

| Thermal Stability | Up to 500degC | Up to 700degC |

| Moisture Absorption | Low | Moderate |

| Cost | High | Low |

| Common Applications | Ballistic armor, aerospace, automotive | Construction, marine, insulation |

Introduction to Composite Materials

Aramid fiber and glass fiber are both essential reinforcement materials widely used in composite manufacturing, each offering unique mechanical properties suitable for various applications. Aramid fiber, like Kevlar, provides exceptional tensile strength, impact resistance, and lightweight characteristics, making it ideal for high-performance composites in aerospace, military, and automotive industries. Glass fiber, known for its cost-effectiveness, high stiffness, and good corrosion resistance, remains a popular choice for structural components, sports equipment, and marine applications.

Aramid Fiber: Properties and Characteristics

Aramid fiber exhibits exceptional tensile strength, high impact resistance, and excellent thermal stability, making it ideal for advanced composite applications. Its low density and superior energy absorption properties provide enhanced durability and flexibility compared to glass fiber. Aramid fiber's resistance to abrasion and chemical degradation further extends the lifespan of composite materials in demanding environments.

Glass Fiber: Properties and Characteristics

Glass fiber exhibits high tensile strength, excellent corrosion resistance, and superior thermal stability, making it ideal for various composite applications. Its lower cost and ease of manufacturing contribute to widespread use in automotive, aerospace, and construction industries. Despite being heavier and less flexible than aramid fiber, glass fiber offers better resistance to UV radiation and moisture absorption.

Strength and Durability Comparison

Aramid fiber exhibits superior tensile strength and impact resistance compared to glass fiber, making it ideal for applications requiring high durability and lightweight performance. Glass fiber offers excellent compressive strength and is more resistant to moisture and chemicals, which enhances its longevity in harsh environments. The choice between aramid and glass fiber depends on the specific strength and durability requirements of the composite application.

Weight and Density Differences

Aramid fiber exhibits significantly lower density, approximately 1.44 g/cm3, compared to glass fiber's density of about 2.55 g/cm3, resulting in lighter composite materials. The reduced weight of aramid fiber composites enhances performance in aerospace and automotive applications where weight savings are critical. Glass fiber, while denser, offers a more cost-effective solution but at the expense of increased structural weight.

Thermal and Chemical Resistance

Aramid fiber exhibits superior thermal resistance with a high decomposition temperature exceeding 400degC, making it ideal for applications requiring heat endurance compared to glass fiber, which typically withstands temperatures up to 250degC. Chemically, aramid fibers demonstrate excellent resistance to organic solvents and hydrocarbons but may degrade in strong acids and bases, whereas glass fibers offer robust resistance against a broader range of chemicals, including acids, alkalis, and solvents. The combination of these properties makes aramid fibers preferable in high-temperature, chemically moderate environments, while glass fibers are favored for applications demanding comprehensive chemical stability.

Cost Analysis: Aramid vs. Glass Fiber

Aramid fiber typically incurs higher material and processing costs compared to glass fiber due to its superior mechanical properties and specialized manufacturing requirements. Glass fiber remains more cost-effective for large-scale production and applications where high strength-to-weight ratios are less critical. Evaluating lifecycle costs, including durability and performance benefits, often justifies the initial higher investment in aramid fiber for advanced composite applications.

Common Applications in Industry

Aramid fiber is widely used in aerospace, military armor, and high-performance sporting goods due to its exceptional strength-to-weight ratio and impact resistance. Glass fiber is commonly applied in automotive parts, construction materials, and marine industries for its cost-effectiveness and good mechanical properties. Both fibers serve critical roles in composite manufacturing, tailored for specific performance requirements across various industrial sectors.

Environmental Impact and Sustainability

Aramid fiber demonstrates a lower environmental impact compared to glass fiber due to its longer lifecycle and superior strength-to-weight ratio, which reduces material consumption and waste generation. Glass fiber production involves higher energy consumption and emits more CO2, contributing to greater environmental degradation. Aramid fibers also offer better recyclability and durability, enhancing their sustainability profile in composite applications.

Choosing the Right Fiber for Your Composite Needs

Aramid fiber offers exceptional impact resistance, high tensile strength, and excellent fatigue performance, making it ideal for applications requiring durability and lightweight properties. Glass fiber provides superior cost-effectiveness, good tensile strength, and resistance to moisture and chemicals, suitable for general-purpose composites where affordability is key. Selecting between aramid and glass fiber depends on specific composite requirements such as mechanical performance, environmental exposure, and budget constraints to optimize structural integrity and longevity.

Aramid Fiber vs Glass Fiber Infographic

materialdif.com

materialdif.com