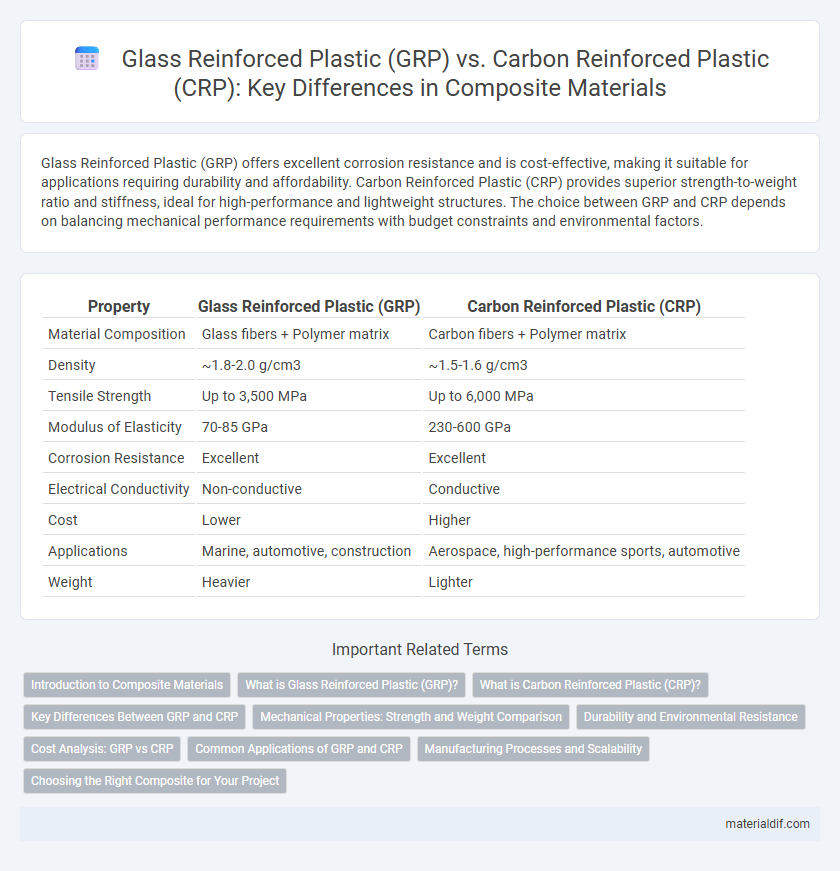

Glass Reinforced Plastic (GRP) offers excellent corrosion resistance and is cost-effective, making it suitable for applications requiring durability and affordability. Carbon Reinforced Plastic (CRP) provides superior strength-to-weight ratio and stiffness, ideal for high-performance and lightweight structures. The choice between GRP and CRP depends on balancing mechanical performance requirements with budget constraints and environmental factors.

Table of Comparison

| Property | Glass Reinforced Plastic (GRP) | Carbon Reinforced Plastic (CRP) |

|---|---|---|

| Material Composition | Glass fibers + Polymer matrix | Carbon fibers + Polymer matrix |

| Density | ~1.8-2.0 g/cm3 | ~1.5-1.6 g/cm3 |

| Tensile Strength | Up to 3,500 MPa | Up to 6,000 MPa |

| Modulus of Elasticity | 70-85 GPa | 230-600 GPa |

| Corrosion Resistance | Excellent | Excellent |

| Electrical Conductivity | Non-conductive | Conductive |

| Cost | Lower | Higher |

| Applications | Marine, automotive, construction | Aerospace, high-performance sports, automotive |

| Weight | Heavier | Lighter |

Introduction to Composite Materials

Glass Reinforced Plastic (GRP) and Carbon Reinforced Plastic (CRP) are widely used composite materials known for their high strength-to-weight ratios and durability. GRP consists of glass fibers embedded in a polymer matrix, offering excellent corrosion resistance and cost-effectiveness, while CRP uses carbon fibers to achieve superior stiffness, tensile strength, and thermal resistance. These composites are increasingly favored in aerospace, automotive, and construction industries for enhancing structural performance and reducing overall weight.

What is Glass Reinforced Plastic (GRP)?

Glass Reinforced Plastic (GRP) is a composite material composed of a polymer matrix reinforced with fine glass fibers, offering high strength-to-weight ratio and corrosion resistance. GRP is widely used in construction, automotive, and marine industries due to its durability, ease of fabrication, and cost-effectiveness compared to other composites. Its mechanical properties provide excellent impact resistance and flexibility, making it suitable for diverse structural applications.

What is Carbon Reinforced Plastic (CRP)?

Carbon Reinforced Plastic (CRP) is a composite material made from carbon fibers embedded in a polymer matrix, offering exceptional strength-to-weight ratios and high stiffness. It is widely used in aerospace, automotive, and sports equipment industries due to its superior mechanical properties and corrosion resistance compared to Glass Reinforced Plastic (GRP). The carbon fibers provide enhanced fatigue resistance and thermal stability, making CRP an ideal choice for high-performance applications requiring lightweight durability.

Key Differences Between GRP and CRP

Glass Reinforced Plastic (GRP) offers high corrosion resistance and cost-effectiveness with moderate strength and flexibility, making it suitable for applications in automotive, marine, and construction industries. Carbon Reinforced Plastic (CRP) provides superior tensile strength, stiffness, and lightweight properties, favored in aerospace, high-performance sports equipment, and advanced engineering sectors. The key differences between GRP and CRP lie in their reinforcing fibers: glass fibers for GRP provide durability and affordability, whereas carbon fibers in CRP deliver enhanced mechanical performance at a higher price point.

Mechanical Properties: Strength and Weight Comparison

Glass Reinforced Plastic (GRP) offers high tensile strength with moderate weight, making it suitable for applications where cost-effectiveness and durability are critical. Carbon Reinforced Plastic (CRP) provides significantly higher strength-to-weight ratio, with tensile strength up to 10 times greater than GRP and substantially lower density, resulting in lighter composite structures. The superior stiffness and fatigue resistance of CRP make it ideal for high-performance aerospace, automotive, and sports equipment requiring both strength and lightweight characteristics.

Durability and Environmental Resistance

Glass Reinforced Plastic (GRP) offers exceptional durability with high resistance to corrosion, moisture, and UV radiation, making it ideal for harsh environmental conditions. Carbon Reinforced Plastic (CRP) also demonstrates strong durability but excels in fatigue resistance and retains structural integrity under extreme temperatures and chemical exposure. Both composites provide superior environmental resistance, though GRP is typically favored for its cost-effective protection against weathering, while CRP is preferred for applications demanding higher mechanical performance and longevity.

Cost Analysis: GRP vs CRP

Glass Reinforced Plastic (GRP) generally offers a lower initial material cost compared to Carbon Reinforced Plastic (CRP), making it a cost-effective choice for large-scale applications. CRP, despite its higher upfront expense, provides superior strength-to-weight ratio and durability, potentially reducing long-term maintenance and operational costs. The cost analysis must consider lifecycle expenses, where GRP suits budget-sensitive projects and CRP benefits high-performance, weight-sensitive designs.

Common Applications of GRP and CRP

Glass Reinforced Plastic (GRP) is widely used in marine, automotive, and construction industries due to its cost-effectiveness, corrosion resistance, and ease of manufacturing. Carbon Reinforced Plastic (CRP) is favored in aerospace, high-performance sports equipment, and automotive racing because of its superior strength-to-weight ratio and stiffness. Both materials serve critical roles in lightweight structural components, with GRP preferred for durability and CRP for performance-driven applications.

Manufacturing Processes and Scalability

Glass Reinforced Plastic (GRP) manufacturing typically involves processes like hand lay-up, spray-up, and filament winding, making it highly adaptable for various product sizes and lower production volumes. Carbon Reinforced Plastic (CRP) requires more precise techniques such as autoclave curing and resin transfer molding, which enhance material performance but demand higher capital investment and longer cycle times. GRP offers greater scalability for mass production due to simpler processing, while CRP excels in high-performance applications where strength-to-weight ratio justifies the increased manufacturing complexity.

Choosing the Right Composite for Your Project

Glass Reinforced Plastic (GRP) offers excellent corrosion resistance and cost-effectiveness, making it ideal for applications requiring durability and budget-friendly materials. Carbon Reinforced Plastic (CRP) provides superior strength-to-weight ratio and stiffness, suitable for high-performance engineering projects where weight reduction is critical. Selecting between GRP and CRP depends on project-specific requirements such as mechanical load, environmental exposure, and financial constraints.

Glass Reinforced Plastic (GRP) vs Carbon Reinforced Plastic (CRP) Infographic

materialdif.com

materialdif.com