Natural fiber composites offer a sustainable alternative to synthetic fiber composites by utilizing renewable resources such as flax, hemp, and jute fibers, which reduce environmental impact. Synthetic fiber composites, typically made from glass or carbon fibers, provide superior strength, durability, and resistance to extreme conditions but often involve higher energy consumption and non-biodegradable waste. Choosing between natural and synthetic fiber composites depends on balancing performance requirements with environmental considerations in various applications.

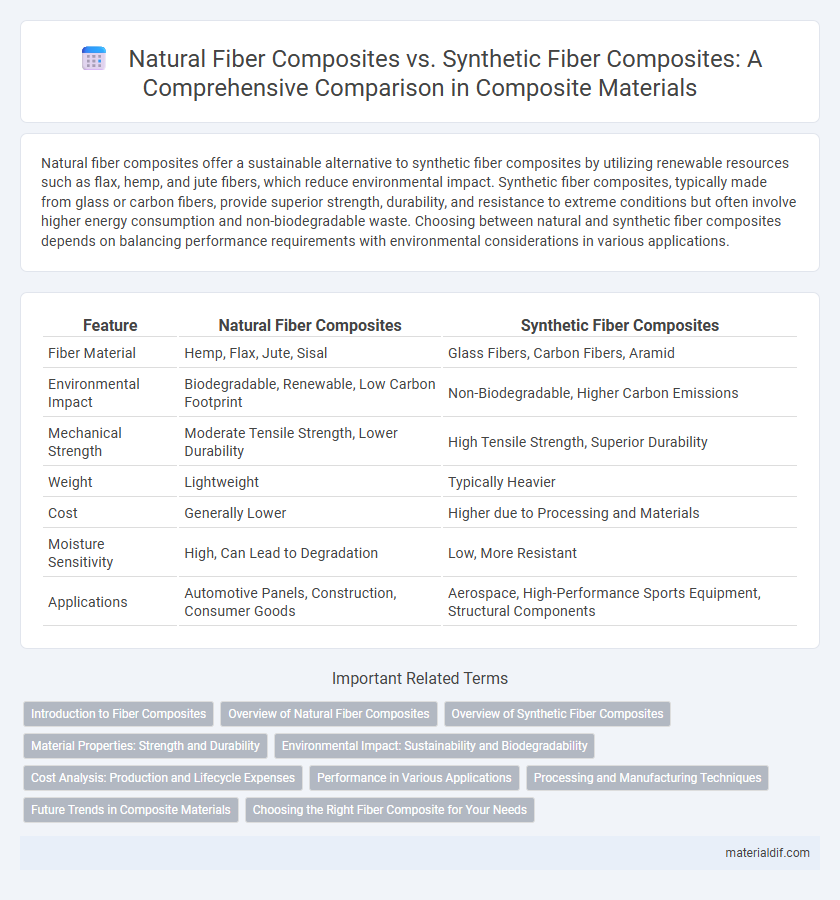

Table of Comparison

| Feature | Natural Fiber Composites | Synthetic Fiber Composites |

|---|---|---|

| Fiber Material | Hemp, Flax, Jute, Sisal | Glass Fibers, Carbon Fibers, Aramid |

| Environmental Impact | Biodegradable, Renewable, Low Carbon Footprint | Non-Biodegradable, Higher Carbon Emissions |

| Mechanical Strength | Moderate Tensile Strength, Lower Durability | High Tensile Strength, Superior Durability |

| Weight | Lightweight | Typically Heavier |

| Cost | Generally Lower | Higher due to Processing and Materials |

| Moisture Sensitivity | High, Can Lead to Degradation | Low, More Resistant |

| Applications | Automotive Panels, Construction, Consumer Goods | Aerospace, High-Performance Sports Equipment, Structural Components |

Introduction to Fiber Composites

Fiber composites combine fibers with a matrix material to create lightweight, high-strength composites used in various industries. Natural fiber composites utilize renewable fibers like hemp, flax, and jute, offering benefits such as biodegradability and lower environmental impact compared to synthetic fiber composites made from glass, carbon, or aramid fibers. These materials exhibit distinct mechanical properties and sustainability profiles, influencing their application in automotive, construction, and consumer products.

Overview of Natural Fiber Composites

Natural fiber composites incorporate fibers such as flax, jute, hemp, and sisal derived from plants, offering renewable and biodegradable alternatives to synthetic fibers like glass or carbon. These composites exhibit advantages in terms of low density, reduced environmental impact, and enhanced energy efficiency during production, making them suitable for automotive, construction, and packaging applications. Challenges remain in their moisture absorption and mechanical performance compared to synthetic fibers, which drives ongoing research in fiber treatment and hybrid composite development.

Overview of Synthetic Fiber Composites

Synthetic fiber composites are engineered materials combining synthetic fibers such as glass, carbon, or aramid with polymer matrices like epoxy or polyester. These composites exhibit high strength-to-weight ratios, excellent durability, and resistance to chemical and environmental degradation. Commonly used in aerospace, automotive, and sports equipment industries, synthetic fiber composites offer tailored mechanical properties for advanced structural applications.

Material Properties: Strength and Durability

Natural fiber composites offer lower density and improved environmental sustainability but typically exhibit reduced tensile strength and impact resistance compared to synthetic fiber composites such as glass or carbon fibers. Synthetic fiber composites provide superior mechanical properties, including higher tensile strength, stiffness, and enhanced durability under cyclic loading and harsh environmental conditions. The choice between natural and synthetic fiber composites depends on the required strength-to-weight ratio, durability demands, and application-specific performance criteria.

Environmental Impact: Sustainability and Biodegradability

Natural fiber composites, derived from renewable resources such as flax, hemp, and jute, offer significant environmental benefits through enhanced sustainability and biodegradability compared to synthetic fiber composites made from non-renewable petrochemical sources like glass or carbon fibers. The production of natural fiber composites generates lower carbon emissions and requires less energy, while their biodegradability reduces landfill waste and supports circular economy initiatives. In contrast, synthetic fiber composites pose environmental challenges due to their persistence in ecosystems and the energy-intensive manufacturing processes involved.

Cost Analysis: Production and Lifecycle Expenses

Natural fiber composites typically have lower production costs due to the abundance and renewability of raw materials like flax, jute, and hemp, reducing initial investment expenses compared to synthetic fibers such as carbon and glass. Lifecycle costs favor natural fiber composites with benefits including biodegradability and reduced disposal fees, while synthetic composites incur higher maintenance and recycling costs. However, synthetic fiber composites often deliver higher durability and performance, potentially offsetting their greater upfront and lifecycle expenses in high-stress applications.

Performance in Various Applications

Natural fiber composites offer enhanced biodegradability and lightweight properties, making them suitable for automotive interiors and consumer goods where environmental impact and weight reduction are critical. Synthetic fiber composites, such as those reinforced with carbon or glass fibers, exhibit superior tensile strength, stiffness, and durability, which are essential for aerospace, construction, and high-performance sporting equipment. Performance variations are influenced by factors like fiber-matrix adhesion, moisture resistance, and impact tolerance, with synthetic fiber composites generally outperforming natural fibers in extreme conditions.

Processing and Manufacturing Techniques

Natural fiber composites often require specialized processing techniques such as low-temperature curing and moisture control to preserve fiber integrity and prevent degradation. Synthetic fiber composites benefit from well-established manufacturing methods like resin transfer molding and automated fiber placement, enabling higher precision and repeatability. Processing natural fibers typically involves additional treatments including alkali treatment or silane coupling agents to enhance fiber-matrix adhesion and composite performance.

Future Trends in Composite Materials

Natural fiber composites are gaining momentum due to their sustainability, biodegradability, and lower carbon footprint compared to synthetic fiber composites. Advances in bio-based resins and hybrid composite technologies are driving improvements in mechanical properties and durability, making natural fiber composites more viable for automotive, aerospace, and construction industries. Future trends highlight the integration of smart materials and nanotechnology to enhance performance and recyclability of both natural and synthetic fiber composites.

Choosing the Right Fiber Composite for Your Needs

Natural fiber composites offer advantages such as biodegradability, lightweight properties, and cost-effectiveness, making them ideal for automotive interiors and consumer goods where sustainability is prioritized. Synthetic fiber composites, including carbon and glass fibers, provide superior strength, durability, and resistance to environmental factors, preferred in aerospace, construction, and high-performance applications. Selecting the right fiber composite depends on balancing factors like mechanical properties, environmental impact, weight requirements, and budget constraints to meet specific performance criteria.

Natural Fiber Composites vs Synthetic Fiber Composites Infographic

materialdif.com

materialdif.com