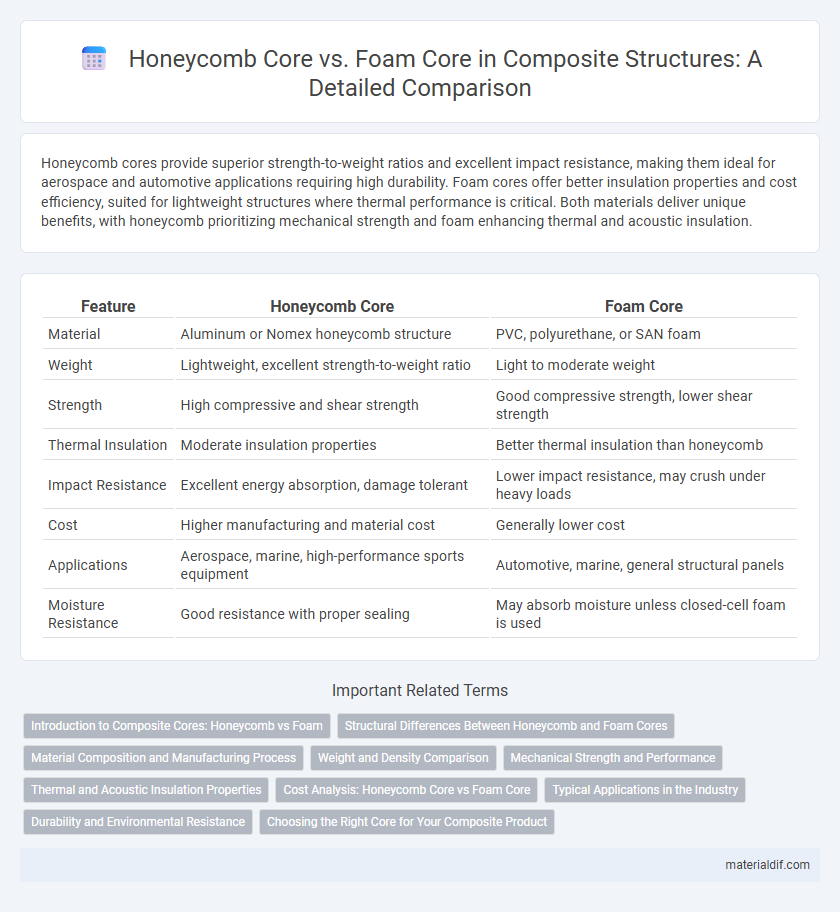

Honeycomb cores provide superior strength-to-weight ratios and excellent impact resistance, making them ideal for aerospace and automotive applications requiring high durability. Foam cores offer better insulation properties and cost efficiency, suited for lightweight structures where thermal performance is critical. Both materials deliver unique benefits, with honeycomb prioritizing mechanical strength and foam enhancing thermal and acoustic insulation.

Table of Comparison

| Feature | Honeycomb Core | Foam Core |

|---|---|---|

| Material | Aluminum or Nomex honeycomb structure | PVC, polyurethane, or SAN foam |

| Weight | Lightweight, excellent strength-to-weight ratio | Light to moderate weight |

| Strength | High compressive and shear strength | Good compressive strength, lower shear strength |

| Thermal Insulation | Moderate insulation properties | Better thermal insulation than honeycomb |

| Impact Resistance | Excellent energy absorption, damage tolerant | Lower impact resistance, may crush under heavy loads |

| Cost | Higher manufacturing and material cost | Generally lower cost |

| Applications | Aerospace, marine, high-performance sports equipment | Automotive, marine, general structural panels |

| Moisture Resistance | Good resistance with proper sealing | May absorb moisture unless closed-cell foam is used |

Introduction to Composite Cores: Honeycomb vs Foam

Composite cores play a crucial role in sandwich structures, enhancing strength and reducing weight by combining two face sheets with a lightweight core material. Honeycomb cores, typically made from aluminum or Nomex, provide exceptional stiffness and high compressive strength due to their hexagonal cell structure, making them ideal for aerospace and automotive applications. Foam cores, such as PVC or polyurethane, offer excellent impact resistance and easier fabrication while maintaining good thermal insulation, preferred in marine and wind energy industries.

Structural Differences Between Honeycomb and Foam Cores

Honeycomb core structures feature a hexagonal cell pattern made from materials like aluminum or Nomex, providing superior strength-to-weight ratios and excellent resistance to shear forces. Foam cores, typically composed of PVC, PET, or SAN, offer uniform density and ease of machining but generally exhibit lower compressive strength and stiffness compared to honeycomb cores. The open-cell geometry in honeycomb allows for enhanced load distribution and energy absorption, whereas foam cores rely on material bulk for structural support.

Material Composition and Manufacturing Process

Honeycomb core is comprised of lightweight hexagonal cells made from materials such as aluminum, Nomex, or paper, providing exceptional strength-to-weight ratio, while foam core consists of solid polymeric foams like PVC, polyurethane, or polystyrene, offering consistent density and shock absorption. The manufacturing process of honeycomb core involves expanding and bonding thin sheets into a honeycomb structure, allowing for high stiffness and load distribution, whereas foam cores are typically produced through foaming or molding techniques to create uniform, closed-cell structures. Both cores are integrated between composite face sheets using adhesives or resin infusion, but the honeycomb structure excels in applications demanding superior strength and weight reduction.

Weight and Density Comparison

Honeycomb cores provide superior strength-to-weight ratios with densities typically ranging from 32 to 96 kg/m3, making them lighter than most foam cores which generally have densities between 48 and 320 kg/m3. Foam cores, such as PVC or polyurethane, often offer higher density options but increase overall weight and reduce structural efficiency. Choosing honeycomb cores enhances weight savings in composite panels, critical for aerospace and automotive applications demanding minimal mass and high stiffness.

Mechanical Strength and Performance

Honeycomb core structures exhibit superior mechanical strength and stiffness-to-weight ratios compared to foam cores, making them ideal for high-performance aerospace and automotive applications. The unique hexagonal cell geometry of honeycomb cores provides exceptional resistance to shear forces and impact, enhancing overall structural integrity. Foam cores, while lighter and easier to shape, generally offer lower compressive strength and fatigue resistance, limiting their use in demanding load-bearing environments.

Thermal and Acoustic Insulation Properties

Honeycomb core materials excel in thermal insulation by trapping air within their hexagonal cells, creating barriers against heat transfer, which makes them ideal for applications requiring lightweight yet effective thermal management. Foam core composites provide superior acoustic insulation due to their porous structure that absorbs and dampens sound waves more efficiently than honeycomb cores. Comparing both, foam cores often deliver enhanced soundproofing performance, while honeycomb cores maintain a better balance between structural rigidity and thermal resistance in composite constructions.

Cost Analysis: Honeycomb Core vs Foam Core

Honeycomb core materials typically have higher initial costs compared to foam cores due to their complex manufacturing and superior strength-to-weight ratio, making them ideal for aerospace and high-performance applications. Foam cores offer lower material and production expenses, making them cost-effective for automotive and marine industries with less stringent structural requirements. A thorough cost analysis must factor in long-term performance benefits and potential maintenance savings, where honeycomb cores often provide better durability and impact resistance, justifying their upfront investment.

Typical Applications in the Industry

Honeycomb core materials are widely used in aerospace and automotive industries due to their excellent strength-to-weight ratio and energy absorption capabilities, making them ideal for structural panels and aircraft flooring. Foam cores find typical applications in marine and wind energy sectors, providing buoyancy and vibration damping in boat hulls and wind turbine blades. Both core types enhance composite sandwich structures but are selected based on specific load-bearing and environmental requirements in industry applications.

Durability and Environmental Resistance

Honeycomb core composites exhibit superior durability compared to foam core due to their unique hexagonal structure, which provides excellent load distribution and impact resistance. They resist environmental degradation better, offering enhanced moisture resistance and longevity in harsh conditions such as UV exposure and temperature extremes. Foam cores, while lightweight and cost-effective, tend to absorb water and degrade faster, making honeycomb cores the preferred choice for applications requiring high durability and environmental resilience.

Choosing the Right Core for Your Composite Product

Honeycomb core offers superior strength-to-weight ratio and excellent impact resistance, making it ideal for aerospace and automotive composite products requiring high structural performance. Foam core provides greater flexibility and cost-effectiveness, suitable for applications where weight reduction and ease of fabrication are prioritized, such as marine and sporting goods. Selecting the right core depends on balancing mechanical requirements, environmental exposure, and budget constraints to optimize the overall composite product performance.

Honeycomb Core vs Foam Core Infographic

materialdif.com

materialdif.com