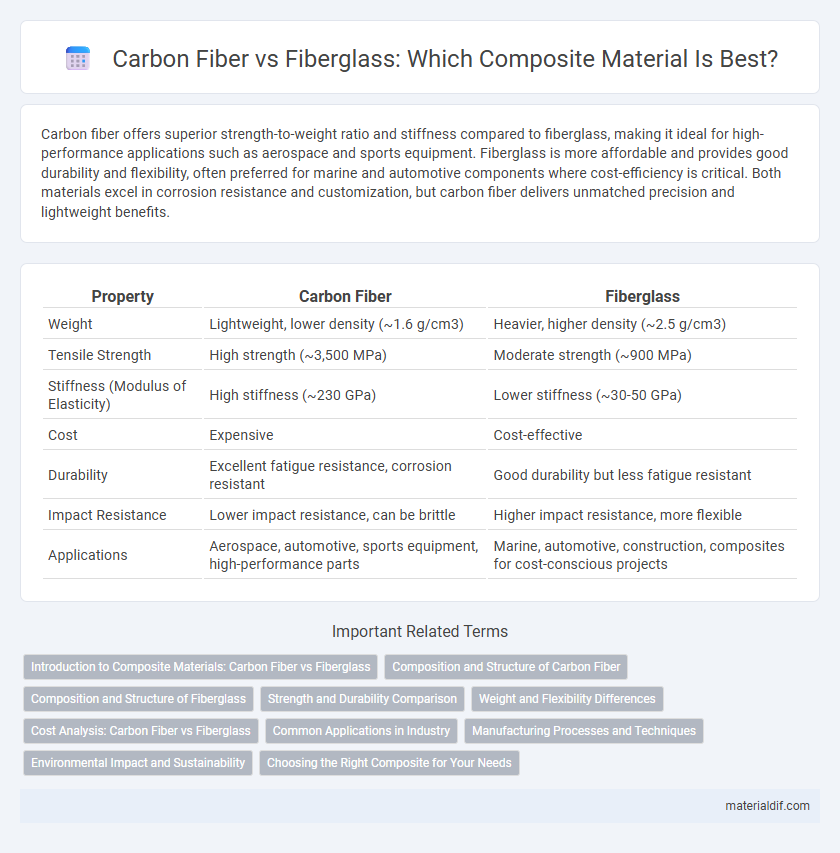

Carbon fiber offers superior strength-to-weight ratio and stiffness compared to fiberglass, making it ideal for high-performance applications such as aerospace and sports equipment. Fiberglass is more affordable and provides good durability and flexibility, often preferred for marine and automotive components where cost-efficiency is critical. Both materials excel in corrosion resistance and customization, but carbon fiber delivers unmatched precision and lightweight benefits.

Table of Comparison

| Property | Carbon Fiber | Fiberglass |

|---|---|---|

| Weight | Lightweight, lower density (~1.6 g/cm3) | Heavier, higher density (~2.5 g/cm3) |

| Tensile Strength | High strength (~3,500 MPa) | Moderate strength (~900 MPa) |

| Stiffness (Modulus of Elasticity) | High stiffness (~230 GPa) | Lower stiffness (~30-50 GPa) |

| Cost | Expensive | Cost-effective |

| Durability | Excellent fatigue resistance, corrosion resistant | Good durability but less fatigue resistant |

| Impact Resistance | Lower impact resistance, can be brittle | Higher impact resistance, more flexible |

| Applications | Aerospace, automotive, sports equipment, high-performance parts | Marine, automotive, construction, composites for cost-conscious projects |

Introduction to Composite Materials: Carbon Fiber vs Fiberglass

Carbon fiber and fiberglass are two prominent materials used in composite structures, each offering distinct mechanical properties and applications. Carbon fiber composites boast exceptional strength-to-weight ratios and high stiffness, making them ideal for aerospace, automotive, and high-performance sporting goods. Fiberglass composites provide superior impact resistance and cost-effectiveness, commonly utilized in marine, construction, and consumer product industries.

Composition and Structure of Carbon Fiber

Carbon fiber is composed primarily of thin strands of pure carbon tightly woven into a fabric, bonded with a polymer resin matrix, typically epoxy, creating a lightweight yet incredibly strong composite. Its atomic structure features tightly packed carbon atoms arranged in microscopic crystals aligned parallel to the fiber axis, providing high tensile strength and stiffness. This crystalline structure differentiates carbon fiber from fiberglass, which consists of glass fibers with a random amorphous structure, resulting in lower strength and rigidity.

Composition and Structure of Fiberglass

Fiberglass consists of fine glass fibers woven into a fabric and combined with a resin matrix, typically polyester or epoxy, forming a lightweight and durable composite material. Unlike carbon fiber, which uses carbon strands with higher tensile strength and stiffness, fiberglass offers greater flexibility and impact resistance at a lower cost. The composite structure of fiberglass provides excellent corrosion resistance and electrical insulation, making it ideal for a variety of industrial and recreational applications.

Strength and Durability Comparison

Carbon fiber exhibits superior tensile strength and stiffness compared to fiberglass, making it ideal for applications requiring high strength-to-weight ratios. Fiberglass offers greater impact resistance and flexibility, enhancing durability in environments susceptible to sudden shocks or bending. The long-term durability of carbon fiber composites is also enhanced by their resistance to fatigue and environmental degradation, whereas fiberglass may suffer more from moisture absorption and UV exposure over time.

Weight and Flexibility Differences

Carbon fiber composites offer superior strength-to-weight ratio compared to fiberglass, making them significantly lighter for equivalent rigidity. Fiberglass provides greater flexibility and impact resistance, which can be advantageous in applications requiring durability under dynamic loads. Carbon fiber's stiffness results in less flex under stress, benefiting high-performance uses where precision and reduced weight are critical.

Cost Analysis: Carbon Fiber vs Fiberglass

Carbon fiber composites typically cost between $10 to $20 per pound, significantly higher than fiberglass, which ranges from $1 to $5 per pound. The higher expense of carbon fiber stems from its energy-intensive manufacturing process and raw material costs, while fiberglass offers a more budget-friendly option for large-scale or less performance-critical applications. Despite the initial investment, carbon fiber's superior strength-to-weight ratio and durability often justify the cost in high-performance industries such as aerospace and automotive.

Common Applications in Industry

Carbon fiber composites dominate aerospace and automotive industries due to their exceptional strength-to-weight ratio and rigidity, making them ideal for structural components and high-performance parts. Fiberglass composites find widespread use in marine, construction, and wind energy sectors, valued for their corrosion resistance, cost-effectiveness, and ease of fabrication in hulls, panels, and turbine blades. Advanced sports equipment, such as racing bicycles and tennis rackets, often incorporate carbon fiber for enhanced performance, while fiberglass remains preferred in water tanks and roofing materials.

Manufacturing Processes and Techniques

Carbon fiber manufacturing involves high-temperature curing in autoclaves and precise layering of carbon fibers pre-impregnated with epoxy resin, delivering superior strength-to-weight ratios. Fiberglass production typically uses hand lay-up or spray-up methods with woven glass fibers combined with polyester or vinyl ester resins, offering cost-effective scalability and simpler fabrication. Advanced techniques like resin transfer molding (RTM) and vacuum infusion are applied in both composites but vary in parameters to optimize fiber alignment and resin flow for each material's distinct mechanical properties.

Environmental Impact and Sustainability

Carbon fiber composites offer superior strength-to-weight ratios but present higher environmental costs due to energy-intensive manufacturing and limited recycling options. Fiberglass composites contribute less to carbon emissions during production and are easier to recycle, making them a more sustainable choice for environmentally conscious applications. Lifecycle assessments consistently show fiberglass composites have a lower overall environmental impact compared to carbon fiber equivalents.

Choosing the Right Composite for Your Needs

Carbon fiber offers superior strength-to-weight ratio and stiffness, making it ideal for high-performance applications like aerospace and sports equipment. Fiberglass provides excellent durability and cost-effectiveness, suited for marine, automotive, and general industrial uses. Select carbon fiber when lightweight and high strength are critical, while fiberglass is preferable for budget-conscious projects requiring impact resistance and flexibility.

Carbon Fiber vs Fiberglass Infographic

materialdif.com

materialdif.com