Woven mats feature continuous strands woven into a fabric, providing superior strength and stiffness, ideal for structural applications requiring high impact resistance. Chopped strand mats consist of randomly oriented short fibers bonded with a binder, offering better conformability to complex shapes and faster resin impregnation. Choosing between woven mat and chopped strand mat depends on the balance between mechanical performance and ease of molding in composite fabrication.

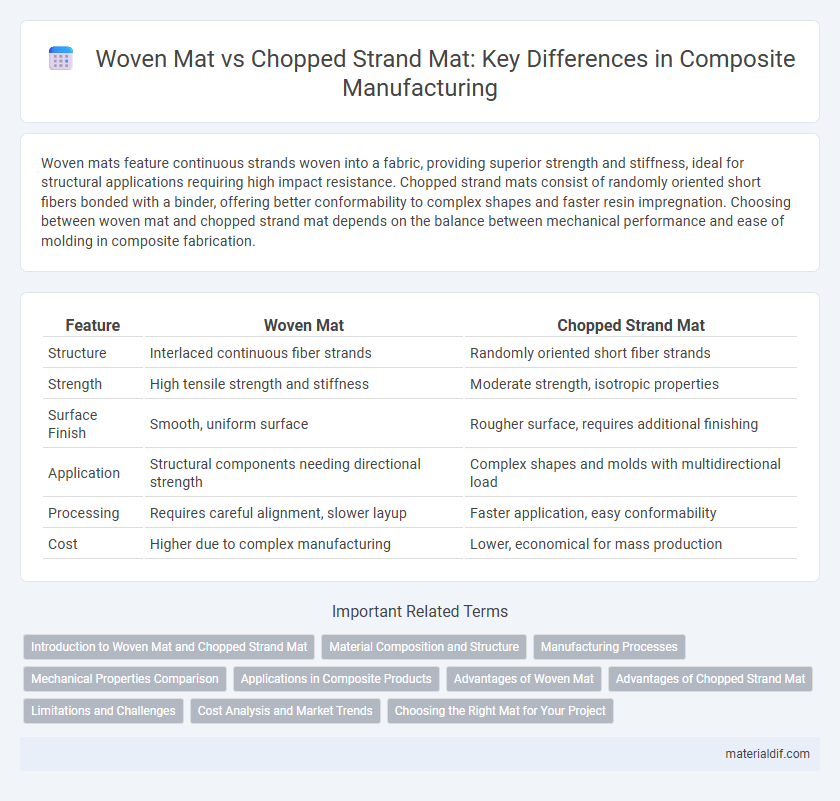

Table of Comparison

| Feature | Woven Mat | Chopped Strand Mat |

|---|---|---|

| Structure | Interlaced continuous fiber strands | Randomly oriented short fiber strands |

| Strength | High tensile strength and stiffness | Moderate strength, isotropic properties |

| Surface Finish | Smooth, uniform surface | Rougher surface, requires additional finishing |

| Application | Structural components needing directional strength | Complex shapes and molds with multidirectional load |

| Processing | Requires careful alignment, slower layup | Faster application, easy conformability |

| Cost | Higher due to complex manufacturing | Lower, economical for mass production |

Introduction to Woven Mat and Chopped Strand Mat

Woven mat and chopped strand mat are essential reinforcements used in composite manufacturing, offering distinct mechanical properties for various applications. Woven mats feature interlaced fibers creating a balanced strength and improved dimensional stability, suitable for load-bearing structures. Chopped strand mats consist of randomly oriented short fibers bonded with a resin, providing isotropic strength and excellent surface finish in molded composites.

Material Composition and Structure

Woven mats consist of continuous fibers interlaced at right angles, providing enhanced tensile strength and dimensional stability, often made from glass or carbon fibers. Chopped strand mats comprise randomly oriented short fiber strands bonded by a binder, resulting in isotropic properties that facilitate ease of molding complex shapes. Material composition in woven mats typically involves unidirectional or bidirectional fabrics, whereas chopped strand mats use discontinuous fibers, impacting mechanical performance and resin impregnation.

Manufacturing Processes

Woven mats are produced through interlacing continuous glass fibers in a crisscross pattern, ensuring high tensile strength and dimensional stability in composite materials. Chopped strand mats consist of randomly oriented short glass fibers bonded by a resin or binder, allowing faster production and improved conformity to complex shapes. The manufacturing process of woven mats requires weaving machinery, while chopped strand mats are typically manufactured by chopping continuous fibers and depositing them on a conveyor belt with binders before curing.

Mechanical Properties Comparison

Woven mats exhibit superior tensile strength and impact resistance compared to chopped strand mats due to their continuous fiber structure, which enhances load distribution and durability. Chopped strand mats offer better conformability to complex shapes but generally have lower stiffness and tensile modulus, limiting their use in high-performance structural applications. The choice between woven and chopped strand mats ultimately depends on the mechanical requirements of the composite part, with woven mats preferred for high-strength, rigid components and chopped strand mats favored for ease of fabrication and cost-effectiveness.

Applications in Composite Products

Woven mats provide superior strength and are commonly used in structural composite products such as automotive body panels, aerospace components, and sporting goods, where load-bearing capacity and impact resistance are critical. Chopped strand mats offer excellent conformability and are ideal for complex shapes in applications like boat hulls, marine parts, and corrosion-resistant tanks due to their ease of molding and good mechanical properties. Selection between woven mats and chopped strand mats depends on the specific performance requirements and manufacturing constraints of composite products.

Advantages of Woven Mat

Woven mats offer higher tensile strength and better dimensional stability compared to chopped strand mats, making them ideal for load-bearing composite structures. Their interlaced fiber architecture enhances impact resistance and fatigue performance, improving durability in demanding applications. The uniform fiber distribution in woven mats also facilitates superior resin infiltration, resulting in stronger and more consistent composite laminates.

Advantages of Chopped Strand Mat

Chopped strand mat offers superior conformability and ease of handling compared to woven mat, making it ideal for complex shapes and curved surfaces. Its random fiber orientation ensures isotropic strength and improved impact resistance in composite laminates. Chopped strand mat also enhances resin flow and wetting, resulting in better bonding and reduced void content within the composite structure.

Limitations and Challenges

Woven mats exhibit limitations in conformability for complex shapes, leading to potential resin-rich areas and reduced mechanical performance. Chopped strand mats face challenges in achieving uniform fiber distribution, which can result in inconsistent strength and increased resin consumption. Both materials require careful process control to mitigate issues such as fiber misalignment and resin voids that impact overall composite durability.

Cost Analysis and Market Trends

Woven mats, known for their higher tensile strength and durability, typically command a premium price compared to chopped strand mats, which offer cost-effective solutions for budget-conscious composite manufacturing. Market trends indicate increasing demand for chopped strand mats in automotive and marine industries due to their lightweight properties and ease of use, while woven mats maintain strong presence in aerospace and high-performance applications. Cost analysis reveals that although woven mats involve higher material and processing expenses, their enhanced mechanical properties provide long-term value in structural composite components.

Choosing the Right Mat for Your Project

Selecting the right mat for composite projects depends on performance requirements and application specifics. Woven mats provide superior strength and stiffness due to their interlaced fibers, ideal for structural components and load-bearing parts. Chopped strand mats offer better conformability and ease of application for complex shapes, making them suitable for molds and curved surfaces where uniform reinforcement is needed.

Woven Mat vs Chopped Strand Mat Infographic

materialdif.com

materialdif.com