Unidirectional (UD) composites provide exceptional strength and stiffness along a single axis due to their aligned fiber orientation, making them ideal for load-bearing applications requiring high tensile strength. In contrast, woven roving composites offer balanced mechanical properties in multiple directions, thanks to their interlaced fiber structure, which enhances impact resistance and dimensional stability. Selecting between UD and woven roving depends on the specific structural demands, with UD favored for directional strength and woven roving chosen for balanced performance and flexibility.

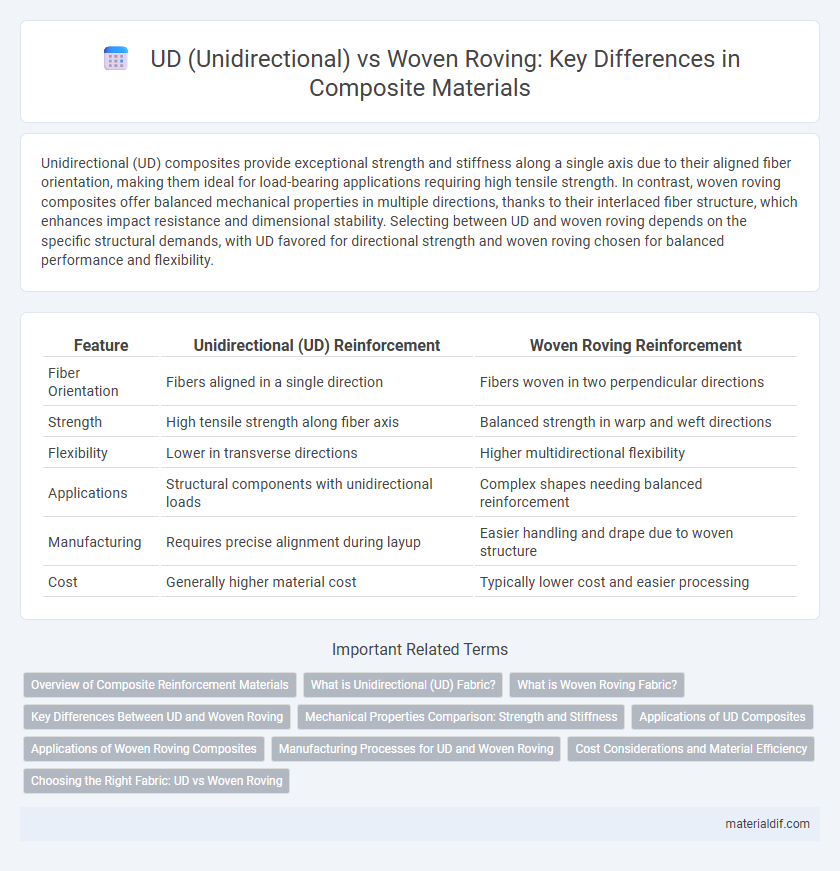

Table of Comparison

| Feature | Unidirectional (UD) Reinforcement | Woven Roving Reinforcement |

|---|---|---|

| Fiber Orientation | Fibers aligned in a single direction | Fibers woven in two perpendicular directions |

| Strength | High tensile strength along fiber axis | Balanced strength in warp and weft directions |

| Flexibility | Lower in transverse directions | Higher multidirectional flexibility |

| Applications | Structural components with unidirectional loads | Complex shapes needing balanced reinforcement |

| Manufacturing | Requires precise alignment during layup | Easier handling and drape due to woven structure |

| Cost | Generally higher material cost | Typically lower cost and easier processing |

Overview of Composite Reinforcement Materials

Unidirectional (UD) composites feature fibers aligned in a single direction, providing maximum strength and stiffness along that axis, ideal for structural components requiring high tensile strength. Woven roving composite reinforcements consist of interlaced fiber bundles in perpendicular directions, offering balanced mechanical properties and enhanced impact resistance due to fiber crimping. The choice between UD and woven roving materials depends on specific load requirements, with UD favored for directional strength and woven roving for multidirectional stress distribution in composite structures.

What is Unidirectional (UD) Fabric?

Unidirectional (UD) fabric consists of continuous fibers aligned in a single direction, maximizing tensile strength along the fiber axis for enhanced structural performance. This fabric type is widely used in composites where high stiffness and strength are critical, such as aerospace and automotive components. Unlike woven roving, UD fabric provides superior load-bearing capacity by minimizing fiber crimp and resin-rich areas, optimizing the composite's mechanical properties.

What is Woven Roving Fabric?

Woven roving fabric consists of continuous glass fibers woven into a reinforcement textile, providing high strength and dimensional stability in composite applications. Unlike unidirectional (UD) fabrics that align fibers in a single direction, woven roving features fibers interlaced in both warp and weft directions, enhancing resistance to multi-directional stress. Its balanced fiber architecture makes woven roving ideal for structures requiring high impact resistance and improved structural integrity.

Key Differences Between UD and Woven Roving

UD (Unidirectional) composites feature fibers aligned in a single direction, offering superior tensile strength and stiffness along that axis, ideal for applications requiring high load-bearing capacity. Woven roving composites consist of fibers interlaced in two perpendicular directions, providing enhanced dimensional stability and balanced mechanical properties suitable for multidirectional stress. The choice between UD and woven roving impacts the composite's strength, flexibility, and resistance to delamination, determining its suitability for specific structural demands in aerospace, automotive, and marine industries.

Mechanical Properties Comparison: Strength and Stiffness

Unidirectional (UD) composites exhibit superior tensile strength and stiffness along the fiber direction due to the continuous alignment of fibers, making them ideal for load-bearing applications requiring maximum mechanical performance. In contrast, woven roving composites provide more balanced strength and stiffness in multiple directions, enhancing impact resistance and dimensional stability but generally offering lower tensile properties compared to UD laminates. The choice between UD and woven roving depends on specific mechanical property requirements such as directional strength or multi-axial durability in composite design.

Applications of UD Composites

UD composites exhibit superior directional strength and stiffness, making them ideal for aerospace components, sporting goods, and high-performance automotive parts where targeted load-bearing capacity is critical. Their unidirectional fiber alignment enables efficient stress transfer along the fiber axis, enhancing fatigue resistance and structural integrity in wind turbine blades and pressure vessels. Compared to woven roving, UD composites offer greater customization in fiber orientation, optimizing mechanical properties for advanced engineering applications requiring precise anisotropic behavior.

Applications of Woven Roving Composites

Woven roving composites are extensively utilized in marine, automotive, and industrial applications due to their superior strength, impact resistance, and dimensional stability compared to unidirectional fabrics. Their balanced fiber orientation enables enhanced multi-directional load distribution, making them ideal for structural components such as boat hulls, vehicle panels, and storage tanks. These properties ensure durability and reliability in environments subject to dynamic stresses and harsh conditions.

Manufacturing Processes for UD and Woven Roving

Unidirectional (UD) composites are manufactured by aligning continuous fibers in a single direction, creating high tensile strength along that axis through processes such as filament winding or tape laying. Woven roving involves interlacing fibers in perpendicular directions using weaving machines, providing balanced strength and improved impact resistance in multiple directions. The manufacturing process for UD emphasizes precise fiber placement to optimize load-bearing capacity, while woven roving focuses on fabric formation that offers structural stability and ease of handling in composite molding.

Cost Considerations and Material Efficiency

Unidirectional (UD) composites typically offer higher material efficiency by aligning fibers in a single direction, resulting in superior strength-to-weight ratios and optimized resin usage, which can lower overall production costs. Woven roving composites, while generally less costly per unit of fabric due to simpler manufacturing processes, often involve higher resin consumption and waste, leading to increased material expenses in large-scale applications. Evaluating project-specific requirements for load-bearing orientation and budget constraints is essential to determine the most cost-effective composite reinforcement choice.

Choosing the Right Fabric: UD vs Woven Roving

Choosing the right composite fabric between UD (Unidirectional) and woven roving depends on specific mechanical properties and application requirements. UD fabrics offer superior tensile strength and stiffness along a single axis, ideal for load-bearing structures, while woven roving provides more balanced, multi-directional strength with enhanced impact resistance. Material engineers prioritize tensile modulus, fiber architecture, and resin compatibility when selecting between UD and woven roving for optimized performance in aerospace, automotive, and marine composites.

UD (Unidirectional) vs Woven Roving Infographic

materialdif.com

materialdif.com