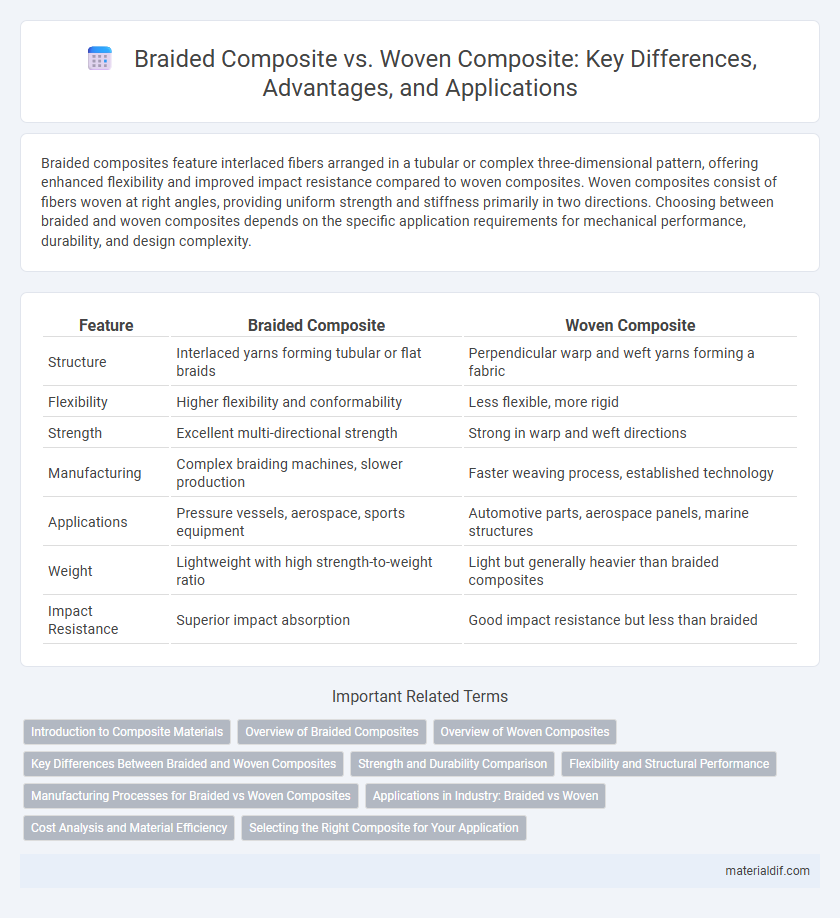

Braided composites feature interlaced fibers arranged in a tubular or complex three-dimensional pattern, offering enhanced flexibility and improved impact resistance compared to woven composites. Woven composites consist of fibers woven at right angles, providing uniform strength and stiffness primarily in two directions. Choosing between braided and woven composites depends on the specific application requirements for mechanical performance, durability, and design complexity.

Table of Comparison

| Feature | Braided Composite | Woven Composite |

|---|---|---|

| Structure | Interlaced yarns forming tubular or flat braids | Perpendicular warp and weft yarns forming a fabric |

| Flexibility | Higher flexibility and conformability | Less flexible, more rigid |

| Strength | Excellent multi-directional strength | Strong in warp and weft directions |

| Manufacturing | Complex braiding machines, slower production | Faster weaving process, established technology |

| Applications | Pressure vessels, aerospace, sports equipment | Automotive parts, aerospace panels, marine structures |

| Weight | Lightweight with high strength-to-weight ratio | Light but generally heavier than braided composites |

| Impact Resistance | Superior impact absorption | Good impact resistance but less than braided |

Introduction to Composite Materials

Braided composites feature interlaced fibers arranged in a diagonal pattern, offering enhanced flexibility and damage tolerance compared to woven composites, which consist of orthogonally interwoven fibers providing higher in-plane strength and stiffness. The choice between braided and woven composites depends on application-specific mechanical requirements and manufacturing processes. Understanding fiber architecture in composite materials is essential for optimizing performance in aerospace, automotive, and sporting goods industries.

Overview of Braided Composites

Braided composites consist of fibers interlaced in a diagonal pattern, offering enhanced torsional strength and three-dimensional reinforcement compared to woven composites. This structure improves damage tolerance and impact resistance, making braided composites ideal for aerospace, automotive, and sporting goods applications. The continuous fiber architecture within braided composites provides superior load distribution and structural durability under dynamic stresses.

Overview of Woven Composites

Woven composites consist of interlaced fibers arranged in specific patterns such as plain, twill, or satin weaves, offering enhanced isotropic properties compared to unidirectional composites. They provide high damage tolerance, better drapability, and improved impact resistance, making them suitable for aerospace, automotive, and sporting goods applications. The fiber architecture in woven composites allows for balanced mechanical properties in multiple directions, contributing to structural integrity and performance under complex loading conditions.

Key Differences Between Braided and Woven Composites

Braided composites feature interlaced fibers arranged in a diagonal pattern, enhancing toughness and impact resistance, while woven composites have fibers woven at perpendicular angles, providing superior dimensional stability and strength. Braided structures offer more flexibility and better damage tolerance, making them ideal for complex shapes and dynamic loading conditions compared to the relatively rigid woven composites. The differences in fiber architecture significantly influence mechanical properties, with braided composites excelling in shear and torsional strength, whereas woven composites perform better under tensile and compressive loads.

Strength and Durability Comparison

Braided composites exhibit superior impact resistance and damage tolerance due to their interlaced fiber architecture, which enhances load distribution and energy absorption. Woven composites provide higher dimensional stability and tensile strength along the fiber directions, making them ideal for applications requiring precise shape retention under stress. The trade-off between the two lies in braided composites offering better toughness and fatigue resistance, while woven composites excel in stiffness and structural integrity over prolonged use.

Flexibility and Structural Performance

Braided composites offer superior flexibility and enhanced damage tolerance due to their interlaced fiber architecture, making them ideal for complex shapes and dynamic loading conditions. Woven composites provide higher stiffness and dimensional stability thanks to their orthogonal fiber arrangement, which enhances load distribution and structural integrity. The choice between braided and woven composites depends on specific application requirements, balancing flexibility demands and structural performance criteria.

Manufacturing Processes for Braided vs Woven Composites

Braided composites are manufactured through a process where fibers are interlaced in a diagonal pattern, creating a three-dimensional structure that enhances impact resistance and flexibility. Woven composites, on the other hand, are produced by interlacing fibers at right angles using weaving machinery, resulting in a two-dimensional fabric with high tensile strength and stiffness. The braiding process allows for more complex shapes and near-net shaping, while weaving is better suited for flat or slightly curved surfaces and offers uniform fiber distribution.

Applications in Industry: Braided vs Woven

Braided composites offer superior tensile strength and impact resistance, making them ideal for aerospace components, automotive drive shafts, and sports equipment where complex load-bearing and flexibility are required. Woven composites excel in applications demanding uniform mechanical properties and dimensional stability, such as in marine hulls, wind turbine blades, and industrial piping. The choice between braided and woven composites depends on performance criteria, manufacturing complexity, and specific stress distributions in industrial applications.

Cost Analysis and Material Efficiency

Braided composites offer superior material efficiency by enabling precise fiber placement and reducing resin waste, leading to lower overall production costs compared to woven composites. The complexity of braided manufacturing can increase initial setup expenses, but long-term savings are realized through reduced material usage and improved structural performance. Woven composites generally have lower upfront costs but may result in higher waste and less optimal fiber alignment, affecting cost-effectiveness in large-scale or high-performance applications.

Selecting the Right Composite for Your Application

Braided composites offer superior impact resistance and fatigue strength due to their interlaced fiber architecture, making them ideal for applications requiring high durability and flexural performance. Woven composites provide enhanced dimensional stability and uniform load distribution, which suits structural components exposed to consistent mechanical stress. Selecting the right composite involves analyzing application-specific demands such as load orientation, environmental exposure, and weight constraints to leverage the distinct mechanical properties of braided or woven composites effectively.

Braided Composite vs Woven Composite Infographic

materialdif.com

materialdif.com