Nano-composite PET materials exhibit significantly enhanced mechanical strength, barrier properties, and thermal stability compared to micro-composite PET due to the uniform dispersion of nanoparticles at the molecular scale. The nano-sized fillers increase the surface area and improve interfacial interactions within the polymer matrix, leading to superior performance in packaging and automotive applications. In contrast, micro-composite PET tends to have less consistent property improvements because larger filler particles result in poorer dispersion and weaker bonding with the polymer matrix.

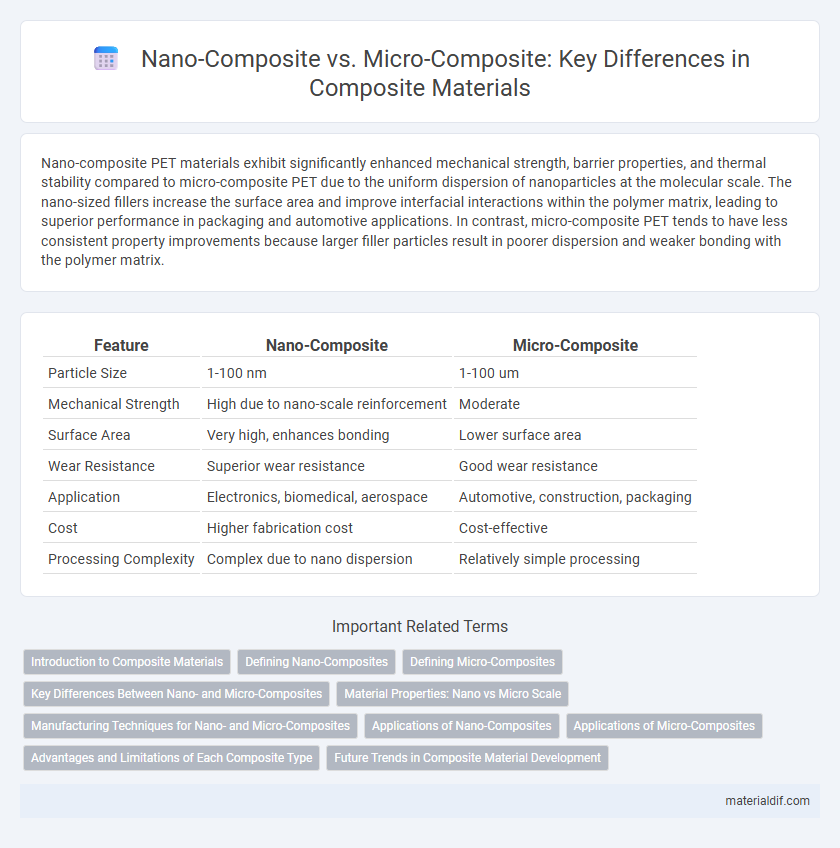

Table of Comparison

| Feature | Nano-Composite | Micro-Composite |

|---|---|---|

| Particle Size | 1-100 nm | 1-100 um |

| Mechanical Strength | High due to nano-scale reinforcement | Moderate |

| Surface Area | Very high, enhances bonding | Lower surface area |

| Wear Resistance | Superior wear resistance | Good wear resistance |

| Application | Electronics, biomedical, aerospace | Automotive, construction, packaging |

| Cost | Higher fabrication cost | Cost-effective |

| Processing Complexity | Complex due to nano dispersion | Relatively simple processing |

Introduction to Composite Materials

Nano-composites and micro-composites differ primarily in the scale of their reinforcing particles, with nano-composites incorporating fillers at the nanometer scale, typically less than 100 nanometers, while micro-composites use micron-sized particles ranging from 1 to 100 micrometers. Nano-composite materials exhibit superior mechanical, thermal, and barrier properties due to the high surface area and enhanced interfacial interaction between the nano-fillers and the matrix. These advanced composites are increasingly utilized in aerospace, automotive, and electronics industries for their improved strength-to-weight ratio and multifunctional capabilities compared to traditional micro-composites.

Defining Nano-Composites

Nano-composites are advanced materials composed of a matrix embedded with particles sized below 100 nanometers, leading to significantly enhanced mechanical, thermal, and electrical properties compared to traditional micro-composites. The nanoscale fillers, such as carbon nanotubes, graphene, or nanoclays, create a large surface area-to-volume ratio, facilitating improved interfacial bonding and load transfer within the composite. This nanoscale structuring results in superior strength, stiffness, and durability, making nano-composites ideal for cutting-edge applications in aerospace, electronics, and biomedical engineering.

Defining Micro-Composites

Micro-composites are composite materials consisting of a matrix embedded with reinforcing fillers measuring between 1 and 100 micrometers in size. These materials enhance mechanical properties such as stiffness, strength, and thermal stability by utilizing microscale particles or fibers like glass or carbon fibers. Micro-composites differ from nano-composites primarily in filler size, where nano-composites incorporate fillers below 100 nanometers, resulting in distinct interfacial and property enhancements.

Key Differences Between Nano- and Micro-Composites

Nano-composites feature filler particles typically less than 100 nanometers in size, resulting in significantly enhanced mechanical, thermal, and barrier properties due to increased surface area and interfacial interaction. Micro-composites contain larger filler particles, usually in the micrometer range, which provide reinforcement but with less pronounced improvements in strength and durability compared to nano-composites. The key differences include particle size, surface-to-volume ratio, and the resulting impact on composite performance attributes such as stiffness, toughness, and thermal stability.

Material Properties: Nano vs Micro Scale

Nano-composites exhibit significantly enhanced mechanical properties, such as increased tensile strength and improved fracture toughness, due to their high surface area-to-volume ratio, which promotes better interfacial bonding between the matrix and the nano-scale fillers. Micro-composites generally show lower improvements in stiffness and strength, as the larger filler particles create stress concentration points and less effective load transfer. The nano-scale reinforcement in nano-composites also contributes to superior thermal stability and improved barrier properties compared to micro-composites.

Manufacturing Techniques for Nano- and Micro-Composites

Manufacturing techniques for nano-composites often involve methods such as sol-gel processing, electrospinning, and in-situ polymerization to achieve uniform nanoparticle dispersion and enhanced interfacial bonding. Micro-composites typically utilize conventional manufacturing processes like mechanical mixing, melt blending, and compression molding, which are optimized for larger filler particles but may result in less homogeneous distribution. Advanced techniques like high-shear mixing and ultrasonic dispersion are critical in nano-composite fabrication to prevent agglomeration and improve mechanical, thermal, and electrical properties.

Applications of Nano-Composites

Nano-composites exhibit superior mechanical strength, thermal stability, and electrical conductivity compared to micro-composites, making them ideal for advanced applications such as aerospace components, automotive parts, and electronic devices. The high surface area to volume ratio of nanoparticles enhances interfacial bonding, resulting in improved wear resistance and durability in coatings and structural materials. Nano-composites are increasingly utilized in medical implants, sensors, and energy storage systems due to their enhanced functional properties at the nanoscale.

Applications of Micro-Composites

Micro-composites find extensive applications in automotive and aerospace industries due to their enhanced mechanical strength and thermal stability compared to conventional composites. Their larger filler size compared to nano-composites enables cost-effective production of structural components, such as automotive body panels and aircraft interior parts. Industrial applications also include electronic housings and construction materials where improved rigidity and durability are crucial.

Advantages and Limitations of Each Composite Type

Nano-composites offer superior mechanical strength, improved thermal stability, and enhanced barrier properties due to the high surface area of nanoparticles, making them ideal for applications requiring lightweight and high-performance materials. However, they face challenges in uniform dispersion, potential agglomeration, and higher production costs compared to micro-composites. Micro-composites provide easier processing, better dimensional stability, and cost-effectiveness but typically lack the advanced performance characteristics and surface interactions seen in nano-composites.

Future Trends in Composite Material Development

Nano-composites exhibit enhanced mechanical strength, thermal stability, and electrical conductivity compared to micro-composites, driven by the nanoscale reinforcement particles' high surface area to volume ratio. Future trends highlight the integration of multifunctional nanomaterials, such as graphene and carbon nanotubes, enabling advanced composites with superior performance in aerospace, automotive, and electronics industries. Emerging fabrication techniques like additive manufacturing and self-healing nanocomposites promise to revolutionize customizable composite materials with improved durability and environmental sustainability.

Nano-composite vs Micro-composite Infographic

materialdif.com

materialdif.com