Resin infusion offers superior fiber-to-resin ratios, resulting in stronger and lighter composite PET parts compared to traditional hand layup methods. This process reduces air entrapment and minimizes voids, enhancing overall material performance and durability. Hand layup remains cost-effective and versatile but often suffers from inconsistent resin distribution and lower mechanical properties.

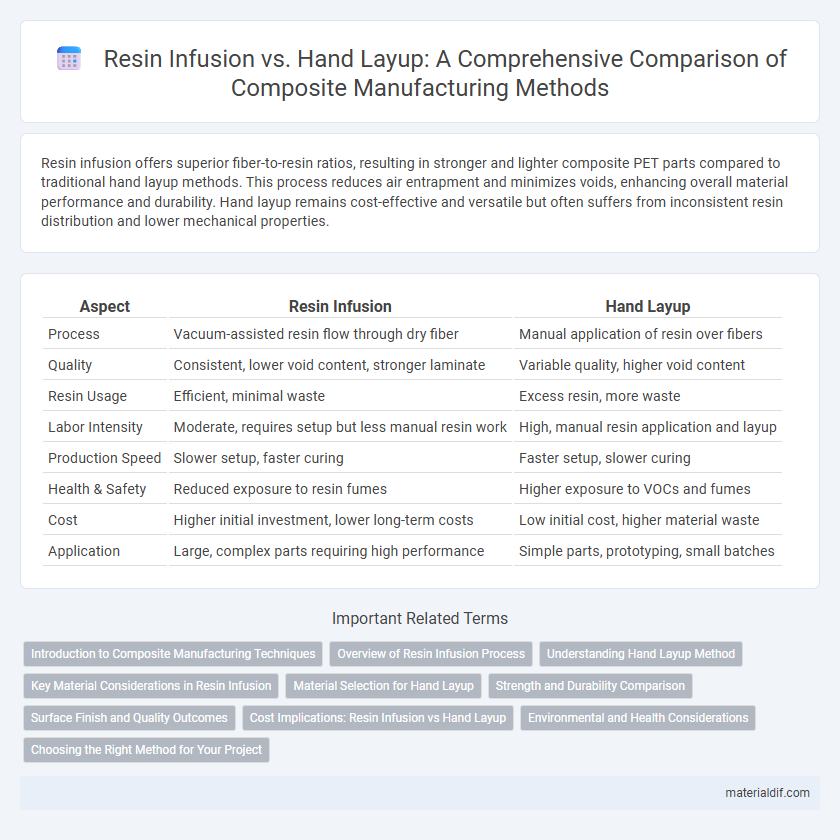

Table of Comparison

| Aspect | Resin Infusion | Hand Layup |

|---|---|---|

| Process | Vacuum-assisted resin flow through dry fiber | Manual application of resin over fibers |

| Quality | Consistent, lower void content, stronger laminate | Variable quality, higher void content |

| Resin Usage | Efficient, minimal waste | Excess resin, more waste |

| Labor Intensity | Moderate, requires setup but less manual resin work | High, manual resin application and layup |

| Production Speed | Slower setup, faster curing | Faster setup, slower curing |

| Health & Safety | Reduced exposure to resin fumes | Higher exposure to VOCs and fumes |

| Cost | Higher initial investment, lower long-term costs | Low initial cost, higher material waste |

| Application | Large, complex parts requiring high performance | Simple parts, prototyping, small batches |

Introduction to Composite Manufacturing Techniques

Resin infusion and hand layup are fundamental composite manufacturing techniques widely used for producing high-strength, lightweight components. Resin infusion offers superior fiber-to-resin ratio and reduced void content by vacuum-sealing dry fibers and drawing resin through the laminate, enhancing mechanical performance and consistency. Hand layup involves manually placing fibers and applying resin, providing flexibility for complex shapes but often resulting in higher voids and less uniformity compared to resin infusion.

Overview of Resin Infusion Process

Resin infusion is an advanced composite manufacturing technique where resin is drawn into dry fiber reinforcement under vacuum pressure, ensuring thorough impregnation and reduced void content. This method enhances laminate quality and mechanical properties, resulting in lightweight, strong composite parts with consistent fiber-to-resin ratios. Unlike hand layup, resin infusion offers improved control over resin distribution, reducing material waste and minimizing defects.

Understanding Hand Layup Method

The hand layup method involves manually placing resin-impregnated fiber layers into a mold to form composite parts, offering cost-effective and flexible production for low-volume applications. This technique requires skilled labor to ensure proper resin distribution and fiber alignment, which directly affect the mechanical properties and surface finish of the final composite structure. Compared to resin infusion, hand layup typically results in higher void content and less consistent resin-to-fiber ratios, impacting the strength and durability of the composite material.

Key Material Considerations in Resin Infusion

Resin infusion requires low-viscosity resin to ensure thorough saturation of dry fiber reinforcements, optimizing fiber-to-resin ratio for enhanced composite strength. The choice of vacuum bag materials and peel ply fabrics directly affects resin flow and air evacuation, crucial for defect-free laminates. Temperature-resistant resins with controlled pot life are preferred to accommodate extended processing times and maintain consistent curing during infusion.

Material Selection for Hand Layup

Material selection for hand layup primarily centers on thermoset resins such as polyester, vinyl ester, and epoxy, chosen for their compatibility with manual application and ambient curing conditions. Reinforcement materials like fiberglass, carbon fiber, or Kevlar are selected based on strength requirements, weight considerations, and cost-effectiveness. Proper resin viscosity and curing profiles are critical to ensure thorough impregnation and adhesion during the hand layup process, directly impacting composite performance and durability.

Strength and Durability Comparison

Resin infusion produces composite parts with superior strength and durability due to its vacuum-driven process, which ensures a higher fiber-to-resin ratio and fewer voids compared to hand layup. The controlled resin flow in resin infusion results in enhanced mechanical properties, making composites more resistant to fatigue and environmental degradation. Hand layup, while simpler, often leads to inconsistent resin distribution and increased porosity, reducing the overall structural integrity of the composite.

Surface Finish and Quality Outcomes

Resin infusion delivers superior surface finish compared to hand layup by minimizing air entrapment and resin-rich areas, resulting in a smoother, more uniform composite surface. The controlled vacuum process in resin infusion ensures higher fiber wet-out and reduced void content, enhancing structural integrity and aesthetic quality. Hand layup, while simpler, often produces inconsistent surface textures and higher variability in resin distribution, affecting overall quality outcomes.

Cost Implications: Resin Infusion vs Hand Layup

Resin infusion typically incurs higher upfront costs due to specialized vacuum equipment and consumables but offers significant material savings and reduced labor expenses in large-scale composite production. Hand layup demands lower initial investment with minimal tooling but often leads to increased labor costs and higher material wastage over time. Evaluating cost implications between resin infusion and hand layup requires analyzing project scale, labor rates, and desired product quality.

Environmental and Health Considerations

Resin infusion reduces volatile organic compound (VOC) emissions compared to hand layup, lowering airborne toxins and improving worker safety. The closed molding process minimizes resin waste and exposure, significantly decreasing environmental pollution and occupational health risks. Hand layup's open exposure to styrene and other harmful chemicals increases respiratory hazards and ecological impact, making resin infusion a more sustainable choice for composite manufacturing.

Choosing the Right Method for Your Project

Resin infusion offers superior strength-to-weight ratios and reduced void content, making it ideal for high-performance composite parts and large, complex structures. Hand layup provides greater flexibility and lower initial costs, suitable for small-scale projects or prototypes with simpler geometries. Selecting the right method depends on factors like part size, production volume, required mechanical properties, and budget constraints.

Resin Infusion vs Hand Layup Infographic

materialdif.com

materialdif.com