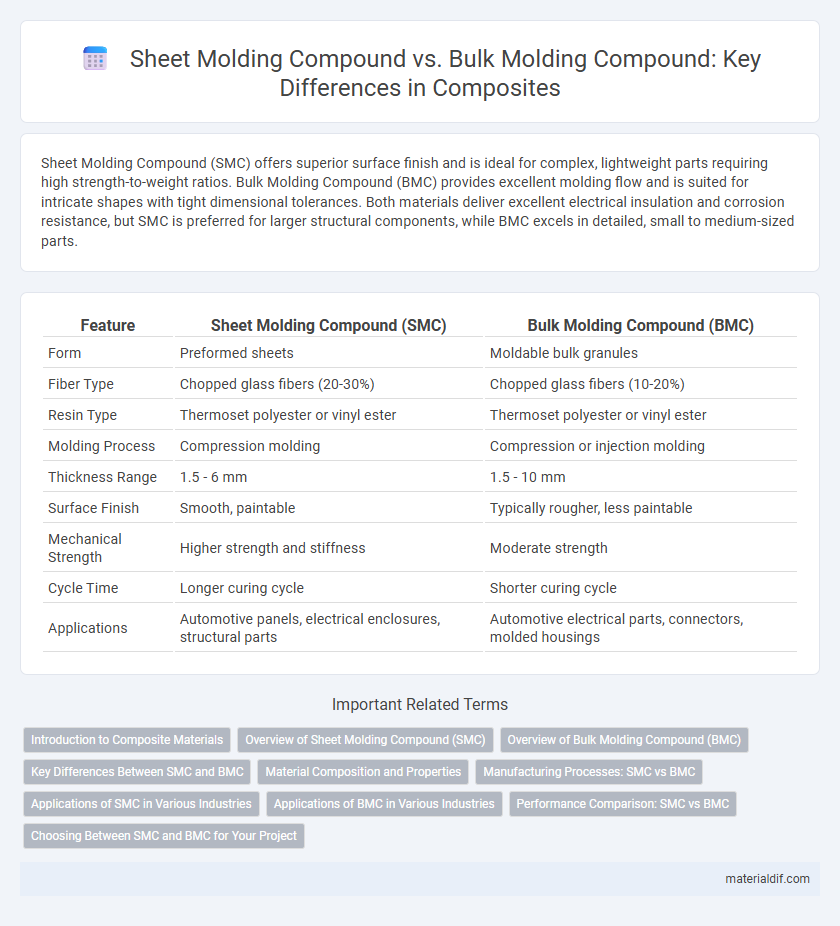

Sheet Molding Compound (SMC) offers superior surface finish and is ideal for complex, lightweight parts requiring high strength-to-weight ratios. Bulk Molding Compound (BMC) provides excellent molding flow and is suited for intricate shapes with tight dimensional tolerances. Both materials deliver excellent electrical insulation and corrosion resistance, but SMC is preferred for larger structural components, while BMC excels in detailed, small to medium-sized parts.

Table of Comparison

| Feature | Sheet Molding Compound (SMC) | Bulk Molding Compound (BMC) |

|---|---|---|

| Form | Preformed sheets | Moldable bulk granules |

| Fiber Type | Chopped glass fibers (20-30%) | Chopped glass fibers (10-20%) |

| Resin Type | Thermoset polyester or vinyl ester | Thermoset polyester or vinyl ester |

| Molding Process | Compression molding | Compression or injection molding |

| Thickness Range | 1.5 - 6 mm | 1.5 - 10 mm |

| Surface Finish | Smooth, paintable | Typically rougher, less paintable |

| Mechanical Strength | Higher strength and stiffness | Moderate strength |

| Cycle Time | Longer curing cycle | Shorter curing cycle |

| Applications | Automotive panels, electrical enclosures, structural parts | Automotive electrical parts, connectors, molded housings |

Introduction to Composite Materials

Sheet Molding Compound (SMC) and Bulk Molding Compound (BMC) are both widely used composite materials consisting of a polymer matrix reinforced with glass fibers, offering high strength-to-weight ratios and excellent corrosion resistance. SMC is characterized by its ready-to-mold sheet form, allowing for uniform fiber distribution and superior surface finish, which is ideal for complex, high-volume automotive and aerospace parts. BMC, in contrast, is a moldable, dough-like material suited for smaller, intricate components and provides excellent electrical insulation and thermal stability.

Overview of Sheet Molding Compound (SMC)

Sheet Molding Compound (SMC) is a fiber-reinforced composite material composed of chopped glass fibers, thermosetting resins, fillers, and additives, offering high strength-to-weight ratio and excellent surface finish. Widely used in automotive, electrical, and aerospace industries, SMC provides superior dimensional stability and corrosion resistance compared to conventional bulk molding compounds (BMC). The manufacturing process of SMC involves compression molding, enabling intricate shapes with tight tolerances and consistent mechanical properties.

Overview of Bulk Molding Compound (BMC)

Bulk Molding Compound (BMC) is a ready-to-mold glass fiber-reinforced polyester material known for its excellent electrical insulation, high strength, and corrosion resistance, making it ideal for automotive, electrical, and industrial applications. BMC consists of short glass fibers, thermosetting resin, fillers, and additives uniformly mixed to achieve consistent performance and ease of molding complex shapes with high dimensional stability. Its bulk form allows precise dosing and reduced waste in compression molding processes, providing superior surface finish and mechanical properties compared to other composite materials.

Key Differences Between SMC and BMC

Sheet Molding Compound (SMC) features a thin, layered structure with longer glass fibers, offering superior surface finish and higher mechanical strength compared to Bulk Molding Compound (BMC), which contains shorter fibers in a bulkier form. SMC provides better dimensional stability and is ideal for large, complex parts requiring detailed surface aesthetics, whereas BMC excels in molding smaller, intricate components with faster cycle times due to its higher filler content. The key differences lie in fiber length, form factor, mechanical properties, and suitability for specific applications in automotive, electrical, and industrial sectors.

Material Composition and Properties

Sheet Molding Compound (SMC) consists of chopped glass fibers, thermosetting resin, fillers, and additives uniformly distributed in a sheet form, providing excellent surface finish and high strength-to-weight ratio. Bulk Molding Compound (BMC) contains a similar composition but is supplied as a thick, dough-like material with randomly oriented fibers, resulting in better moldability and complex shape formation. SMC offers superior mechanical properties and corrosion resistance due to its controlled fiber orientation, while BMC excels in rapid production and intricate part details.

Manufacturing Processes: SMC vs BMC

Sheet Molding Compound (SMC) manufacturing involves layering resin, fillers, and fibers into a sheet form, which is then cured under heat and pressure in a compression molding process for precise part shapes and surface finish. Bulk Molding Compound (BMC) production mixes resin, fillers, and chopped fibers into a homogeneous dough-like consistency, which is directly injected or compression molded into molds, enabling complex geometries with shorter cycle times. The key distinction in processes is SMC's use of pre-formed sheets for enhanced surface quality versus BMC's bulk mixture accommodating faster molding and intricate component designs.

Applications of SMC in Various Industries

Sheet Molding Compound (SMC) is widely used in automotive, aerospace, and electrical industries due to its high strength-to-weight ratio, corrosion resistance, and versatility in complex shapes. Its applications include manufacturing automotive body panels, aerospace components, and electrical housings where dimensional stability and surface finish are critical. The ability of SMC to be molded into large, intricate parts makes it ideal for high-volume production in diverse industrial sectors.

Applications of BMC in Various Industries

Bulk Molding Compound (BMC) is extensively utilized across automotive, electrical, and consumer goods industries due to its excellent electrical insulation properties, high strength, and resistance to heat and corrosion. In the automotive sector, BMC is preferred for manufacturing complex parts like housings, connectors, and panels, while in the electrical industry, it is used for circuit breakers, switchgear components, and insulators. The versatility and cost-effectiveness of BMC make it an ideal material for mass production in household appliances and industrial equipment, where durability and precision are crucial.

Performance Comparison: SMC vs BMC

Sheet Molding Compound (SMC) offers superior surface finish and dimensional stability compared to Bulk Molding Compound (BMC), making it ideal for visible automotive panels and structural components. SMC typically exhibits higher tensile strength and better impact resistance due to its continuous fiber orientation, while BMC provides more isotropic mechanical properties suited for complex, smaller parts. Both materials share excellent corrosion resistance and reduce manufacturing cycle times, but the choice depends on the balance between mechanical performance and geometric complexity.

Choosing Between SMC and BMC for Your Project

Choosing between Sheet Molding Compound (SMC) and Bulk Molding Compound (BMC) depends on project requirements such as part complexity, surface finish, and mechanical strength. SMC offers superior surface aesthetics and is ideal for large, complex parts requiring high strength and dimensional stability, while BMC is better suited for intricate, smaller components with fine details. Consider factors like molding cycle time, cost efficiency, and thermal resistance to select the optimal composite material for your application.

Sheet Molding Compound vs Bulk Molding Compound Infographic

materialdif.com

materialdif.com