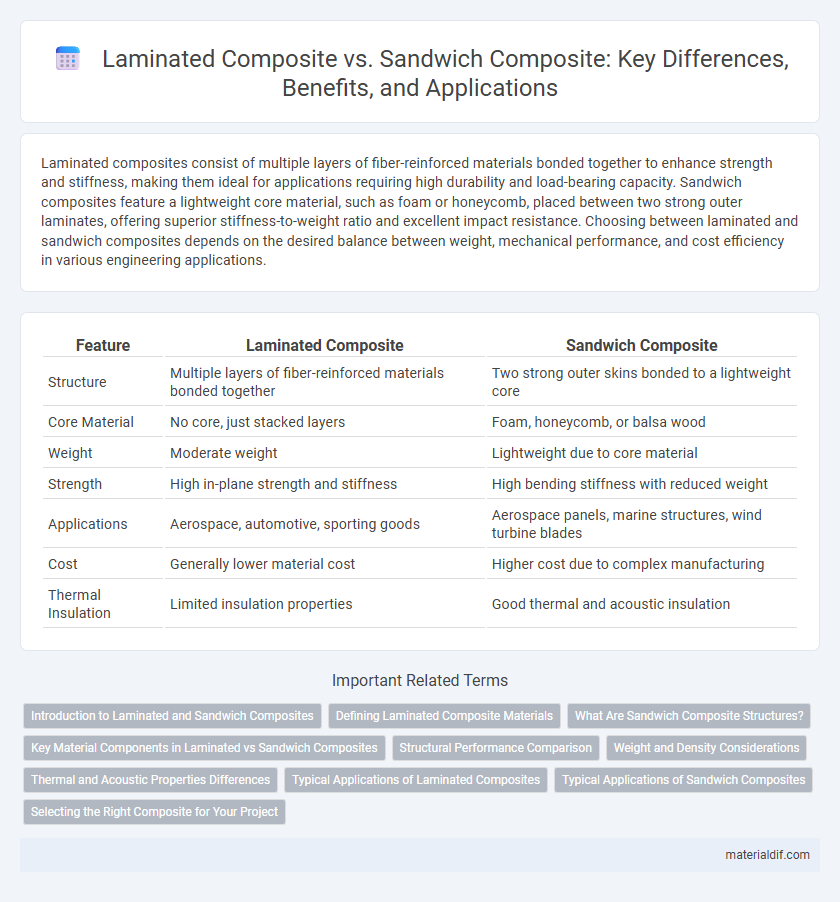

Laminated composites consist of multiple layers of fiber-reinforced materials bonded together to enhance strength and stiffness, making them ideal for applications requiring high durability and load-bearing capacity. Sandwich composites feature a lightweight core material, such as foam or honeycomb, placed between two strong outer laminates, offering superior stiffness-to-weight ratio and excellent impact resistance. Choosing between laminated and sandwich composites depends on the desired balance between weight, mechanical performance, and cost efficiency in various engineering applications.

Table of Comparison

| Feature | Laminated Composite | Sandwich Composite |

|---|---|---|

| Structure | Multiple layers of fiber-reinforced materials bonded together | Two strong outer skins bonded to a lightweight core |

| Core Material | No core, just stacked layers | Foam, honeycomb, or balsa wood |

| Weight | Moderate weight | Lightweight due to core material |

| Strength | High in-plane strength and stiffness | High bending stiffness with reduced weight |

| Applications | Aerospace, automotive, sporting goods | Aerospace panels, marine structures, wind turbine blades |

| Cost | Generally lower material cost | Higher cost due to complex manufacturing |

| Thermal Insulation | Limited insulation properties | Good thermal and acoustic insulation |

Introduction to Laminated and Sandwich Composites

Laminated composites consist of multiple bonded layers of fiber-reinforced materials, offering enhanced strength and stiffness through strategic fiber orientation. Sandwich composites feature a lightweight core material, such as foam or honeycomb, bonded between two thin face sheets, providing superior bending stiffness and impact resistance. Both composite types are widely used in aerospace, automotive, and marine industries for their high strength-to-weight ratios and tailored mechanical properties.

Defining Laminated Composite Materials

Laminated composite materials consist of multiple layers of fiber-reinforced plies bonded together with resin to achieve tailored mechanical properties and enhanced structural performance. Each ply in laminated composites is oriented at specific angles to optimize strength, stiffness, and resistance to delamination under various loading conditions. This layering technique differentiates laminated composites from sandwich composites, which incorporate a lightweight core material between composite face sheets to increase stiffness without significantly adding weight.

What Are Sandwich Composite Structures?

Sandwich composite structures consist of two strong outer face sheets bonded to a lightweight core, providing high strength-to-weight ratio and excellent stiffness. Common core materials include foam, honeycomb, or balsa wood, which effectively resist shear forces while minimizing weight. These composites are widely used in aerospace, automotive, and marine industries due to their enhanced impact resistance and structural efficiency compared to laminated composites.

Key Material Components in Laminated vs Sandwich Composites

Laminated composites primarily consist of multiple layers of fiber-reinforced materials bonded with resin, where fibers like carbon or glass provide strength and stiffness. Sandwich composites feature a lightweight core material such as foam, honeycomb, or balsa wood, sandwiched between two thin laminated composite skins to enhance bending rigidity and reduce weight. The combination of high-strength fiber layers in laminated composites contrasts with the core-skin structure in sandwich composites, optimizing each for different structural performance requirements.

Structural Performance Comparison

Laminated composites exhibit superior stiffness and strength due to their continuous fiber reinforcement layers, making them ideal for load-bearing structural applications. Sandwich composites, composed of two thin, strong face sheets bonded to a lightweight core, offer excellent flexural rigidity and impact resistance while significantly reducing weight. The choice between laminated and sandwich composites depends on balancing the need for high strength-to-weight ratio versus enhanced energy absorption and insulation properties.

Weight and Density Considerations

Laminated composites exhibit higher density due to their solid layered structure, affecting overall weight and load-bearing capacity. Sandwich composites incorporate a lightweight core material bonded between thin face sheets, significantly reducing weight while maintaining stiffness and strength. These differences make sandwich composites preferable in aerospace and automotive applications where minimizing weight is critical without compromising mechanical performance.

Thermal and Acoustic Properties Differences

Laminated composites exhibit superior thermal conductivity due to the continuous fiber layers, allowing efficient heat transfer compared to sandwich composites, which possess a core material that enhances thermal insulation by trapping air pockets. Acoustic performance in sandwich composites is superior as the core material acts as a sound dampener, reducing vibration and noise transmission more effectively than the relatively dense laminated composites. The choice between laminated and sandwich composites depends on the requirement for either enhanced thermal conduction or improved noise reduction in applications.

Typical Applications of Laminated Composites

Laminated composites are widely employed in aerospace structures, automotive components, and sporting goods due to their high strength-to-weight ratio and superior fatigue resistance. Their typical applications include aircraft wings, car body panels, and bicycle frames where durability and stiffness are critical. These composites offer tailored mechanical properties through fiber orientation, making them ideal for load-bearing elements in engineering designs.

Typical Applications of Sandwich Composites

Sandwich composites are widely used in aerospace, marine, and automotive industries due to their high strength-to-weight ratio and excellent energy absorption properties. Typical applications include aircraft fuselage panels, boat hulls, and automotive body structures where lightweight and enhanced stiffness are crucial. These composites also find use in wind turbine blades and sporting goods, benefiting from their superior fatigue resistance and impact absorption.

Selecting the Right Composite for Your Project

When selecting the right composite for your project, laminated composites offer superior strength and stiffness due to their multiple bonded layers of fiber and matrix, ideal for applications requiring high structural integrity. Sandwich composites feature a lightweight core material, such as foam or honeycomb, between two thin laminated skins, providing excellent stiffness-to-weight ratio and energy absorption, making them suitable for aerospace and automotive uses. Evaluating project requirements like load-bearing capacity, weight constraints, and impact resistance ensures optimal composite selection tailored to performance and cost-efficiency.

Laminated Composite vs Sandwich Composite Infographic

materialdif.com

materialdif.com