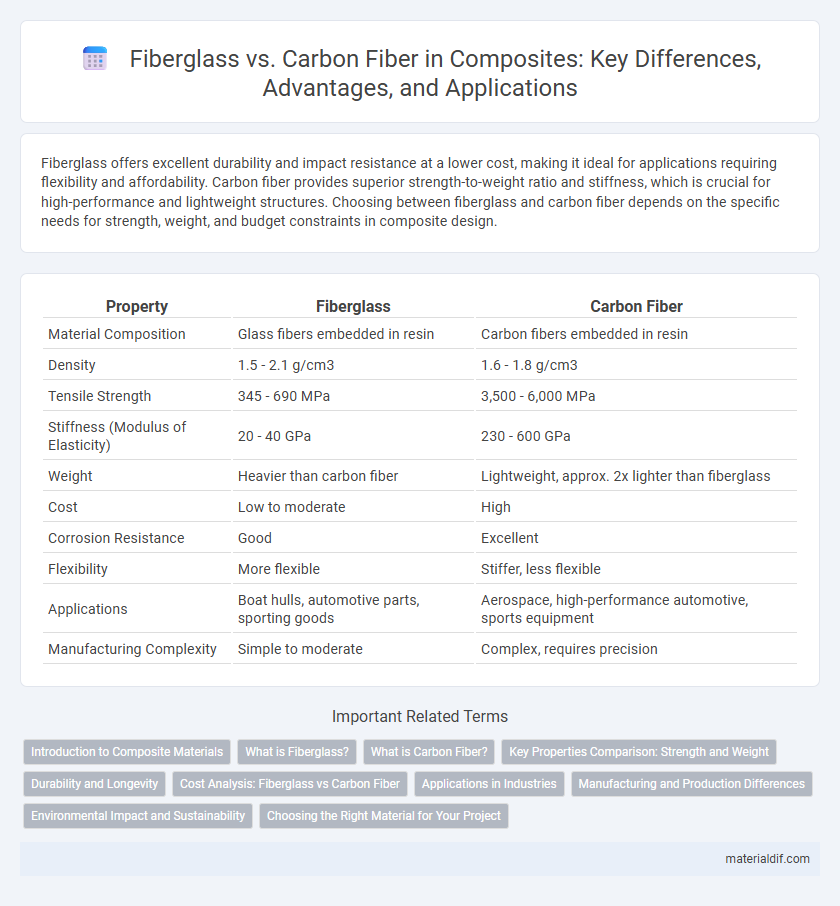

Fiberglass offers excellent durability and impact resistance at a lower cost, making it ideal for applications requiring flexibility and affordability. Carbon fiber provides superior strength-to-weight ratio and stiffness, which is crucial for high-performance and lightweight structures. Choosing between fiberglass and carbon fiber depends on the specific needs for strength, weight, and budget constraints in composite design.

Table of Comparison

| Property | Fiberglass | Carbon Fiber |

|---|---|---|

| Material Composition | Glass fibers embedded in resin | Carbon fibers embedded in resin |

| Density | 1.5 - 2.1 g/cm3 | 1.6 - 1.8 g/cm3 |

| Tensile Strength | 345 - 690 MPa | 3,500 - 6,000 MPa |

| Stiffness (Modulus of Elasticity) | 20 - 40 GPa | 230 - 600 GPa |

| Weight | Heavier than carbon fiber | Lightweight, approx. 2x lighter than fiberglass |

| Cost | Low to moderate | High |

| Corrosion Resistance | Good | Excellent |

| Flexibility | More flexible | Stiffer, less flexible |

| Applications | Boat hulls, automotive parts, sporting goods | Aerospace, high-performance automotive, sports equipment |

| Manufacturing Complexity | Simple to moderate | Complex, requires precision |

Introduction to Composite Materials

Composite materials combine two or more distinct substances to create a material with superior properties, such as enhanced strength, stiffness, and lightweight characteristics. Fiberglass consists of fine glass fibers embedded in a resin matrix, offering excellent durability and cost-effectiveness. Carbon fiber composites provide higher tensile strength and stiffness compared to fiberglass, making them ideal for high-performance applications in aerospace, automotive, and sporting goods.

What is Fiberglass?

Fiberglass is a composite material consisting of fine glass fibers woven into a fabric and bonded with a resin matrix, typically polyester or epoxy. It offers excellent strength-to-weight ratio, corrosion resistance, and electrical insulation, making it ideal for automotive, marine, and construction applications. Compared to carbon fiber, fiberglass is more cost-effective and easier to work with, but it has lower stiffness and tensile strength.

What is Carbon Fiber?

Carbon fiber is a lightweight, high-strength material composed of thin, strong crystalline filaments of carbon tightly woven and bonded with resin to form a composite. It offers superior stiffness, tensile strength, and resistance to fatigue compared to fiberglass, making it ideal for aerospace, automotive, and sporting goods applications. The material's low weight and exceptional mechanical properties enable enhanced performance and fuel efficiency in advanced engineering designs.

Key Properties Comparison: Strength and Weight

Fiberglass offers a tensile strength of approximately 3450 MPa and weighs around 2.5 g/cm3, making it durable and moderately lightweight for many applications. Carbon fiber exhibits superior strength with tensile values reaching up to 6000 MPa while maintaining a lower density near 1.6 g/cm3, resulting in a stronger yet lighter composite. The significant weight advantage and high strength-to-weight ratio of carbon fiber make it preferable for high-performance designs requiring maximum structural efficiency.

Durability and Longevity

Fiberglass offers high durability with excellent resistance to impact and corrosion, making it suitable for applications requiring long-lasting performance under harsh conditions. Carbon fiber excels in longevity due to its superior tensile strength and fatigue resistance, maintaining structural integrity over extended use without significant degradation. Selecting between the two depends on specific durability requirements and environmental exposure in composite materials.

Cost Analysis: Fiberglass vs Carbon Fiber

Fiberglass offers a cost-effective solution with raw material prices significantly lower than carbon fiber, often costing around $2 to $6 per pound compared to carbon fiber's $10 to $20 per pound. Manufacturing processes for fiberglass are less complex and require less specialized equipment, reducing production expenses. Despite higher upfront costs, carbon fiber's superior strength-to-weight ratio can lead to long-term savings in applications demanding performance and durability.

Applications in Industries

Fiberglass is widely used in automotive and marine industries due to its cost-effectiveness, corrosion resistance, and ease of molding into complex shapes. Carbon fiber dominates aerospace and high-performance sports equipment sectors because of its superior strength-to-weight ratio and rigidity. Both materials find applications in wind energy for turbine blades, balancing durability and weight requirements based on specific engineering demands.

Manufacturing and Production Differences

Fiberglass manufacturing relies on a relatively low-cost, straightforward process involving weaving glass fibers into mats or cloths before impregnation with resin, enabling mass production with flexible mold compatibility. Carbon fiber production involves complex steps such as polyacrylonitrile (PAN) precursor stabilization, carbonization at high temperatures, and surface treatment, resulting in higher material costs and longer production cycles. The distinct thermal curing requirements and automation levels create significant variability in scalability and repeatability between fiberglass and carbon fiber composite fabrication.

Environmental Impact and Sustainability

Fiberglass production consumes more energy and generates higher levels of airborne pollutants compared to carbon fiber, which is partially offset by its longer lifespan and recyclability options. Carbon fiber offers superior strength-to-weight ratio leading to enhanced fuel efficiency in transportation applications, indirectly reducing carbon emissions. Both materials face challenges in end-of-life recycling, but recent advancements in recycling carbon fiber composites promote improved sustainability outcomes.

Choosing the Right Material for Your Project

Fiberglass offers excellent impact resistance, affordability, and ease of fabrication, making it ideal for projects requiring durability and cost-efficiency. Carbon fiber provides superior strength-to-weight ratio, stiffness, and fatigue resistance, suited for high-performance applications like aerospace and automotive industries. Selecting the right material depends on balancing factors such as budget, mechanical properties, weight considerations, and project-specific requirements.

Fiberglass vs Carbon Fiber Infographic

materialdif.com

materialdif.com