Carbon Fiber Reinforced Polymer (CFRP) offers superior strength-to-weight ratio and stiffness compared to Glass Fiber Reinforced Polymer (GFRP), making it ideal for high-performance applications requiring lightweight durability. GFRP is more cost-effective and provides good corrosion resistance, suitable for less demanding structural uses and environments where budget constraints are critical. Both composites exhibit excellent resistance to fatigue and environmental degradation, but CFRP typically outperforms GFRP in mechanical properties and thermal stability.

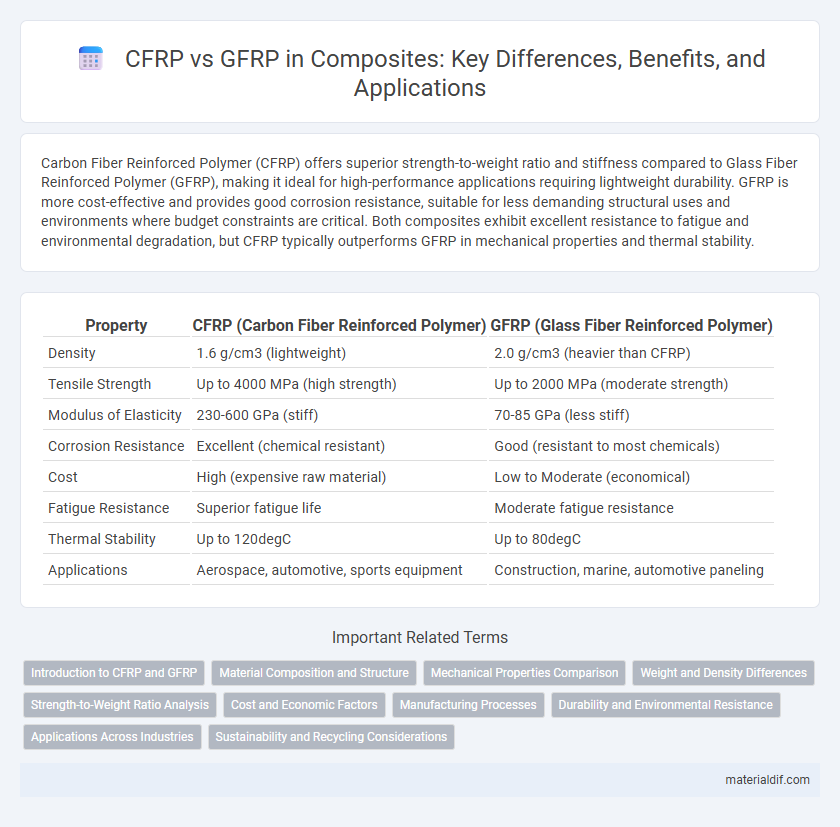

Table of Comparison

| Property | CFRP (Carbon Fiber Reinforced Polymer) | GFRP (Glass Fiber Reinforced Polymer) |

|---|---|---|

| Density | 1.6 g/cm3 (lightweight) | 2.0 g/cm3 (heavier than CFRP) |

| Tensile Strength | Up to 4000 MPa (high strength) | Up to 2000 MPa (moderate strength) |

| Modulus of Elasticity | 230-600 GPa (stiff) | 70-85 GPa (less stiff) |

| Corrosion Resistance | Excellent (chemical resistant) | Good (resistant to most chemicals) |

| Cost | High (expensive raw material) | Low to Moderate (economical) |

| Fatigue Resistance | Superior fatigue life | Moderate fatigue resistance |

| Thermal Stability | Up to 120degC | Up to 80degC |

| Applications | Aerospace, automotive, sports equipment | Construction, marine, automotive paneling |

Introduction to CFRP and GFRP

Carbon Fiber Reinforced Polymer (CFRP) consists of carbon fibers embedded in a polymer matrix, offering exceptional strength-to-weight ratio and high stiffness, making it ideal for aerospace and automotive applications. Glass Fiber Reinforced Polymer (GFRP) uses glass fibers in a polymer matrix, providing good corrosion resistance and cost-effectiveness with moderate mechanical properties suitable for construction and marine industries. Both composites improve structural performance by combining fiber reinforcement with polymer matrices, but CFRP typically outperforms GFRP in strength and rigidity.

Material Composition and Structure

Carbon Fiber Reinforced Polymer (CFRP) consists of carbon fibers embedded within a polymer matrix, offering high tensile strength, stiffness, and lightweight properties due to the strong covalent bonding in carbon fibers. Glass Fiber Reinforced Polymer (GFRP) incorporates glass fibers in a polymer matrix, providing excellent corrosion resistance and cost-effectiveness but lower strength and stiffness compared to CFRP. The microstructure of CFRP features aligned carbon fibers ensuring superior mechanical performance, while GFRP's randomly orientated glass fibers yield more isotropic properties and greater impact resistance.

Mechanical Properties Comparison

Carbon Fiber Reinforced Polymer (CFRP) exhibits significantly higher tensile strength and stiffness compared to Glass Fiber Reinforced Polymer (GFRP), making it ideal for high-performance structural applications. CFRP's superior fatigue resistance and lower density also enhance its mechanical efficiency, while GFRP offers better impact resistance and cost-effectiveness. The choice between CFRP and GFRP depends on the specific mechanical property requirements such as strength-to-weight ratio, durability, and environmental conditions.

Weight and Density Differences

Carbon Fiber Reinforced Polymer (CFRP) exhibits a significantly lower density, approximately 1.6 g/cm3, compared to Glass Fiber Reinforced Polymer (GFRP), which has a density around 2.0 g/cm3, making CFRP notably lighter for equivalent volume. This weight advantage translates into enhanced strength-to-weight ratios for CFRP, favoring aerospace and automotive applications demanding high performance and fuel efficiency. GFRP, while denser, offers cost-effective solutions and acceptable weight characteristics for structural applications where budget constraints dominate over minimal weight savings.

Strength-to-Weight Ratio Analysis

Carbon Fiber Reinforced Polymer (CFRP) exhibits a significantly higher strength-to-weight ratio compared to Glass Fiber Reinforced Polymer (GFRP), making it ideal for applications demanding maximum strength with minimal weight. The tensile strength of CFRP can reach up to 600 MPa while maintaining a density around 1.6 g/cm3, whereas GFRP typically offers tensile strength near 300 MPa with a higher density of about 2.0 g/cm3. This superior strength-to-weight efficiency allows CFRP to outperform GFRP in aerospace, automotive, and sporting goods where performance and weight savings are critical.

Cost and Economic Factors

Carbon Fiber Reinforced Polymer (CFRP) typically incurs higher initial costs compared to Glass Fiber Reinforced Polymer (GFRP) due to the expensive raw materials and complex manufacturing processes involved. Despite the premium price, CFRP offers superior strength-to-weight ratio and durability, which can lead to reduced maintenance expenses and longer service life, potentially offsetting upfront investments in high-performance applications. In contrast, GFRP provides a more cost-effective solution for projects with budget constraints, albeit with lower mechanical properties and shorter lifespan, influencing economic decisions based on application requirements and lifecycle cost analysis.

Manufacturing Processes

CFRP (Carbon Fiber Reinforced Polymer) manufacturing involves complex processes such as autoclave curing, resin transfer molding, and prepreg layup to achieve high strength-to-weight ratios, whereas GFRP (Glass Fiber Reinforced Polymer) manufacturing commonly utilizes vacuum infusion and hand layup techniques, offering more cost-effective and flexible production. The curing process for CFRP typically requires higher temperatures and pressure, resulting in superior mechanical properties and durability compared to GFRP, which cures at lower temperatures under ambient or slight pressure conditions. Manufacturing efficiency for GFRP is generally higher, making it suitable for large-scale applications, while CFRP demands more precise control and specialized equipment for high-performance parts.

Durability and Environmental Resistance

Carbon Fiber Reinforced Polymer (CFRP) exhibits superior durability and environmental resistance compared to Glass Fiber Reinforced Polymer (GFRP) due to its high tensile strength and chemical stability. CFRP resists moisture, UV radiation, and corrosion more effectively, making it ideal for harsh environments like marine and aerospace applications. GFRP, while cost-effective, tends to degrade faster under prolonged exposure to UV and moisture, compromising its structural integrity over time.

Applications Across Industries

Carbon Fiber Reinforced Polymer (CFRP) is extensively used in aerospace, automotive, and high-performance sports equipment due to its superior strength-to-weight ratio and stiffness. Glass Fiber Reinforced Polymer (GFRP) finds widespread application in construction, marine, and infrastructure industries, favored for its cost-effectiveness and corrosion resistance. The choice between CFRP and GFRP heavily depends on specific performance requirements, budget constraints, and environmental exposure.

Sustainability and Recycling Considerations

Carbon Fiber Reinforced Polymer (CFRP) offers high strength-to-weight ratios but poses significant challenges in recycling due to the energy-intensive processes and limited recovery options. Glass Fiber Reinforced Polymer (GFRP) exhibits more favorable sustainability profiles, with easier recycling methods such as mechanical shredding and reuse in cementitious materials. Innovations in chemical recycling and thermal treatments are advancing for both CFRP and GFRP, aiming to improve circular economy outcomes in composite manufacturing.

CFRP vs GFRP Infographic

materialdif.com

materialdif.com