Balsa core offers superior strength-to-weight ratio and excellent impact resistance, making it ideal for high-performance composite structures. Foam core, while lighter and easier to shape, often lacks the durability and stiffness provided by balsa, which can limit its use in demanding applications. Choosing between balsa core and foam core depends on balancing weight savings with mechanical performance requirements.

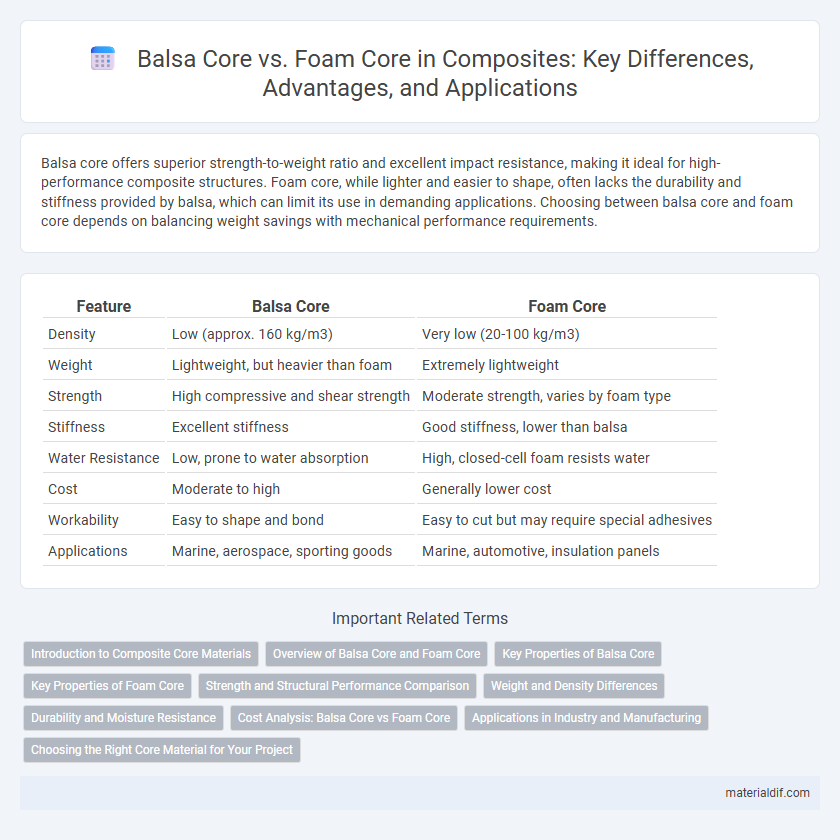

Table of Comparison

| Feature | Balsa Core | Foam Core |

|---|---|---|

| Density | Low (approx. 160 kg/m3) | Very low (20-100 kg/m3) |

| Weight | Lightweight, but heavier than foam | Extremely lightweight |

| Strength | High compressive and shear strength | Moderate strength, varies by foam type |

| Stiffness | Excellent stiffness | Good stiffness, lower than balsa |

| Water Resistance | Low, prone to water absorption | High, closed-cell foam resists water |

| Cost | Moderate to high | Generally lower cost |

| Workability | Easy to shape and bond | Easy to cut but may require special adhesives |

| Applications | Marine, aerospace, sporting goods | Marine, automotive, insulation panels |

Introduction to Composite Core Materials

Balsa core and foam core are fundamental composite core materials used to enhance strength-to-weight ratios in various applications, including aerospace and marine industries. Balsa core offers high stiffness and excellent compressive strength due to its natural cellular structure, while foam core provides superior impact resistance and consistent density with lightweight properties. Selection between balsa and foam cores depends on specific performance requirements such as load-bearing capacity, durability, and environmental conditions.

Overview of Balsa Core and Foam Core

Balsa core is a natural wood material valued for its high strength-to-weight ratio, excellent stiffness, and superior compressive properties, making it ideal for aerospace and marine composite applications. Foam core, typically made from materials like PVC or polyurethane, offers lightweight characteristics, good thermal insulation, and ease of shaping but generally provides lower mechanical strength compared to balsa. Both cores serve as essential sandwich materials in composites, balancing weight reduction with structural integrity based on application-specific requirements.

Key Properties of Balsa Core

Balsa core offers exceptional strength-to-weight ratio, making it a preferred choice in composite sandwich structures for aerospace and marine applications. Its natural cellular structure provides superior compressive strength, stiffness, and excellent impact resistance compared to foam cores. Balsa also boasts superior moisture resistance and thermal stability, enhancing durability in harsh environments.

Key Properties of Foam Core

Foam core offers exceptional lightweight strength and excellent thermal insulation, making it ideal for composite sandwich panels in aerospace and marine applications. Its uniform density and closed-cell structure provide superior moisture resistance and dimensional stability compared to traditional balsa core. Foam core materials such as PVC, PET, and SAN allow for customized mechanical properties, enhancing impact resistance and ease of fabrication in advanced composite manufacturing.

Strength and Structural Performance Comparison

Balsa core offers superior strength-to-weight ratio and exceptional stiffness, making it ideal for high-performance composite structures requiring enhanced load-bearing capabilities. Foam core, while lighter and easier to shape, generally provides lower compressive strength and reduced structural rigidity compared to balsa, limiting its effectiveness in demanding mechanical applications. Engineers select balsa core when maximizing structural performance and impact resistance is critical, whereas foam core suits applications prioritizing weight savings and cost efficiency.

Weight and Density Differences

Balsa core offers a higher strength-to-weight ratio with a typical density of 160-320 kg/m3, making it lighter yet more durable compared to foam core materials like PVC or PMI, which usually range from 30-200 kg/m3. Foam cores are less dense and absorb less water but often require thicker sections to match the mechanical properties of balsa, resulting in increased weight. The choice between balsa and foam cores significantly impacts the overall composite structure's stiffness, durability, and weight efficiency in applications such as marine and aerospace industries.

Durability and Moisture Resistance

Balsa core offers superior durability in composite structures due to its high strength-to-weight ratio and natural resistance to impact damage, making it ideal for load-bearing applications. Foam core, while lighter, generally exhibits lower durability and can be more susceptible to compression and puncture under stress. In terms of moisture resistance, foam core typically outperforms balsa, as it is less prone to water absorption and swelling, which is critical for marine and humid environment applications.

Cost Analysis: Balsa Core vs Foam Core

Balsa core offers a higher strength-to-weight ratio but typically comes at a higher material cost compared to foam core, making it a premium option for high-performance composites. Foam cores, such as PVC or PET, usually present lower initial expenses and easier machining, providing cost-effective solutions for less demanding applications. When evaluating total project costs, including labor and material waste, foam cores often reduce overall expenses despite lower structural performance versus balsa cores.

Applications in Industry and Manufacturing

Balsa core offers exceptional strength-to-weight ratio and superior impact resistance, making it ideal for aerospace, marine, and high-performance automotive applications where durability and weight savings are critical. Foam core, including PVC and PET variants, provides cost-effective, lightweight solutions favored in wind energy blade manufacturing and architectural panels due to its ease of shaping and thermal insulation properties. Both materials are extensively chosen in composite sandwich structures, with balsa preferred for load-bearing demands and foam core selected for applications requiring moisture resistance and design flexibility.

Choosing the Right Core Material for Your Project

Balsa core offers superior strength-to-weight ratio and excellent compressive strength, making it ideal for aerospace and marine composites where durability is critical. Foam core provides excellent insulation properties and cost-effectiveness, suitable for lightweight applications such as wind turbine blades and automotive panels. Select balsa for high-performance structural needs and foam for projects prioritizing thermal insulation and budget constraints.

Balsa Core vs Foam Core Infographic

materialdif.com

materialdif.com