Short fiber composites offer ease of processing and lower manufacturing costs, making them ideal for mass production and complex shapes. Continuous fiber composites exhibit superior mechanical properties, such as higher strength and stiffness, due to the uninterrupted fiber alignment. Choosing between short fiber and continuous fiber composites depends on the application requirements for performance and production efficiency.

Table of Comparison

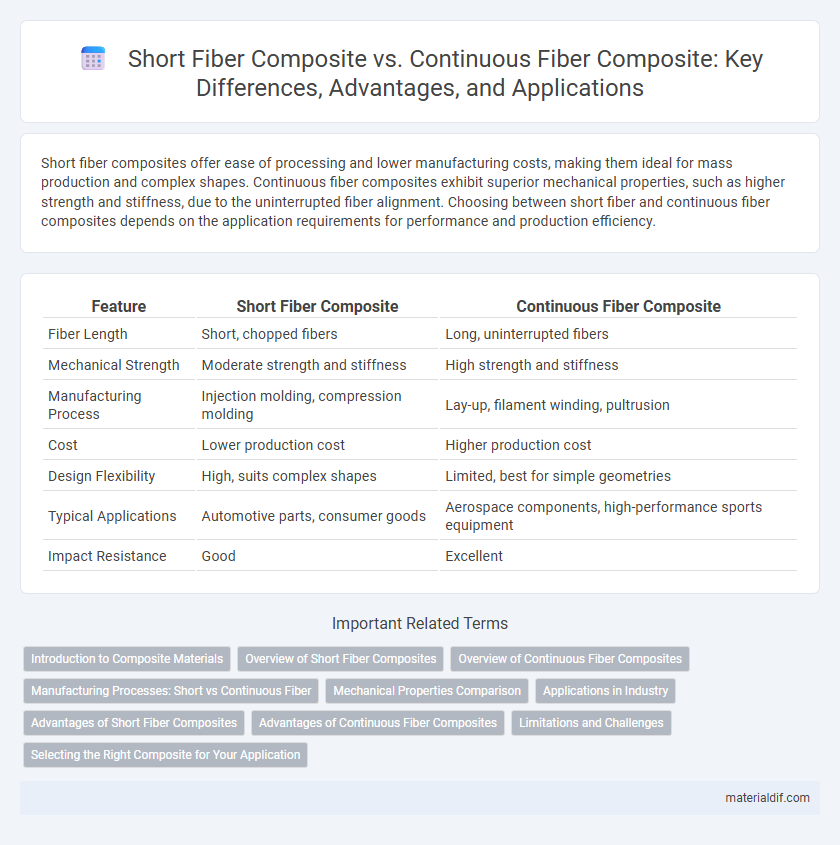

| Feature | Short Fiber Composite | Continuous Fiber Composite |

|---|---|---|

| Fiber Length | Short, chopped fibers | Long, uninterrupted fibers |

| Mechanical Strength | Moderate strength and stiffness | High strength and stiffness |

| Manufacturing Process | Injection molding, compression molding | Lay-up, filament winding, pultrusion |

| Cost | Lower production cost | Higher production cost |

| Design Flexibility | High, suits complex shapes | Limited, best for simple geometries |

| Typical Applications | Automotive parts, consumer goods | Aerospace components, high-performance sports equipment |

| Impact Resistance | Good | Excellent |

Introduction to Composite Materials

Short fiber composites consist of randomly oriented small fibers that enhance isotropic mechanical properties, making them suitable for complex shapes and cost-effective production. Continuous fiber composites feature long, aligned fibers that provide superior strength, stiffness, and directional load-bearing capabilities, ideal for high-performance structural applications. The choice between short and continuous fiber composites depends on the balance between mechanical performance requirements and manufacturing complexity.

Overview of Short Fiber Composites

Short fiber composites consist of discontinuous fibers randomly dispersed within a polymer matrix, offering improved isotropic mechanical properties compared to unreinforced plastics. These composites provide enhanced impact resistance, easier moldability, and lower manufacturing costs, making them suitable for complex shapes and mass production. However, their mechanical strength and stiffness are generally lower than continuous fiber composites due to shorter fiber lengths and limited fiber alignment.

Overview of Continuous Fiber Composites

Continuous fiber composites feature long, unbroken fibers embedded in a matrix, providing exceptional strength and stiffness compared to short fiber composites. These materials exhibit superior load transfer capabilities and enhanced mechanical properties, making them ideal for aerospace, automotive, and sporting goods applications. Common fiber types include carbon, glass, and aramid, which contribute to the composite's high tensile strength and durability.

Manufacturing Processes: Short vs Continuous Fiber

Short fiber composites are typically produced using injection molding or compression molding, allowing for faster cycle times and complex shapes but resulting in lower mechanical properties due to fiber discontinuity. Continuous fiber composites employ processes like filament winding, pultrusion, or layup techniques, which enhance fiber alignment and provide superior strength and stiffness but require longer manufacturing durations and higher labor input. The choice between short and continuous fiber composites hinges on the balance between production efficiency and desired structural performance.

Mechanical Properties Comparison

Short fiber composites exhibit enhanced isotropic mechanical properties with improved impact resistance and ease of fabrication, while continuous fiber composites demonstrate superior tensile strength, stiffness, and load-bearing capacity due to fiber alignment. The mechanical performance of continuous fiber composites surpasses that of short fiber composites in applications requiring high strength-to-weight ratios and fatigue resistance. Short fiber composites provide better damage tolerance and manufacturability but are limited in structural load applications compared to continuous fiber composites.

Applications in Industry

Short fiber composites offer enhanced moldability and cost efficiency, making them ideal for automotive parts, consumer goods, and electronic housings. Continuous fiber composites provide superior strength and stiffness, suited for aerospace structures, wind turbine blades, and high-performance sports equipment. Industrial applications leverage the specific mechanical properties of each composite type to optimize performance and manufacturing processes.

Advantages of Short Fiber Composites

Short fiber composites offer enhanced design flexibility and easier manufacturing processes compared to continuous fiber composites, allowing for complex shapes and cost-effective production. They provide improved impact resistance and isotropic mechanical properties, making them suitable for applications requiring multidirectional strength. Their ability to be processed via injection molding also enables high-volume production, reducing overall material waste and lead times.

Advantages of Continuous Fiber Composites

Continuous fiber composites offer superior mechanical properties, including higher tensile strength and stiffness compared to short fiber composites. Their unidirectional fiber alignment enables more efficient load transfer and improved fatigue resistance, making them ideal for structural applications. These composites also provide enhanced durability and better impact resistance, leading to longer service life in demanding environments.

Limitations and Challenges

Short fiber composites face limitations in achieving high mechanical strength and stiffness due to fiber length and orientation variability, resulting in anisotropic properties and reduced load transfer efficiency. Continuous fiber composites provide superior strength and fatigue resistance but encounter challenges in complex shaping, manufacturing costs, and maintaining fiber alignment during production. Both types struggle with issues like matrix-fiber adhesion, environmental degradation, and repair difficulties, impacting long-term performance and lifecycle sustainability.

Selecting the Right Composite for Your Application

Short fiber composites offer enhanced isotropic strength and ease of molding, making them suitable for complex geometries and high-volume production. Continuous fiber composites provide superior tensile strength and stiffness, ideal for structural applications requiring maximum load-bearing capacity and minimal weight. Selecting the right composite depends on balancing mechanical performance requirements, manufacturing constraints, and cost considerations specific to the intended application.

Short fiber composite vs Continuous fiber composite Infographic

materialdif.com

materialdif.com