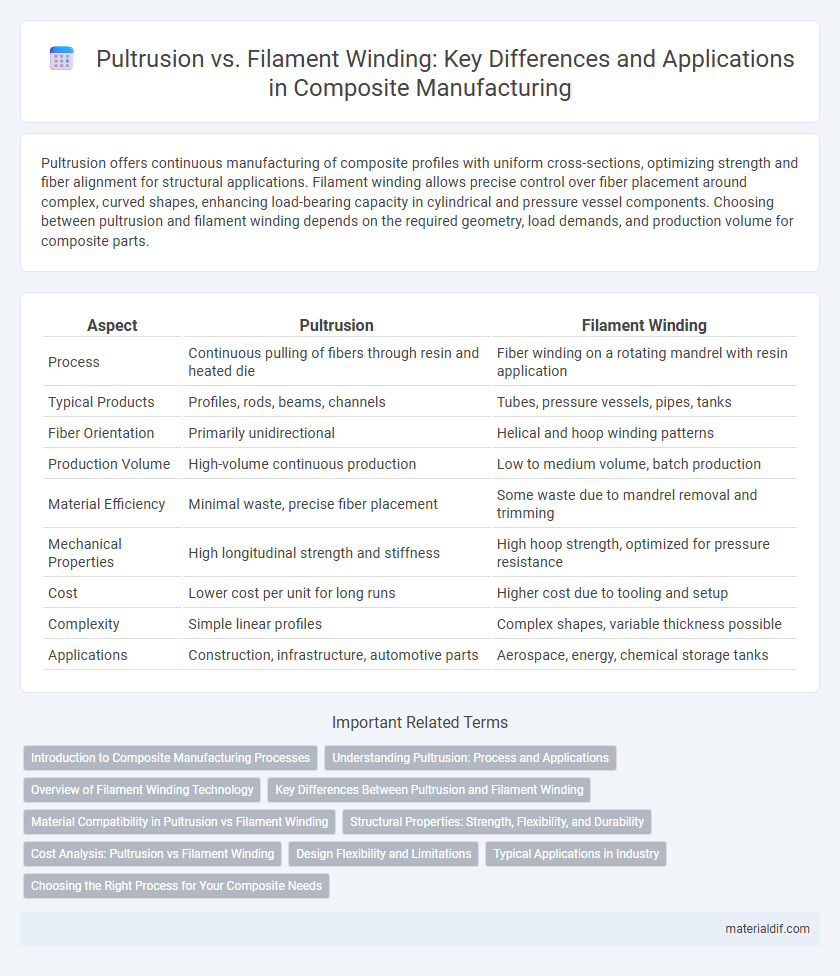

Pultrusion offers continuous manufacturing of composite profiles with uniform cross-sections, optimizing strength and fiber alignment for structural applications. Filament winding allows precise control over fiber placement around complex, curved shapes, enhancing load-bearing capacity in cylindrical and pressure vessel components. Choosing between pultrusion and filament winding depends on the required geometry, load demands, and production volume for composite parts.

Table of Comparison

| Aspect | Pultrusion | Filament Winding |

|---|---|---|

| Process | Continuous pulling of fibers through resin and heated die | Fiber winding on a rotating mandrel with resin application |

| Typical Products | Profiles, rods, beams, channels | Tubes, pressure vessels, pipes, tanks |

| Fiber Orientation | Primarily unidirectional | Helical and hoop winding patterns |

| Production Volume | High-volume continuous production | Low to medium volume, batch production |

| Material Efficiency | Minimal waste, precise fiber placement | Some waste due to mandrel removal and trimming |

| Mechanical Properties | High longitudinal strength and stiffness | High hoop strength, optimized for pressure resistance |

| Cost | Lower cost per unit for long runs | Higher cost due to tooling and setup |

| Complexity | Simple linear profiles | Complex shapes, variable thickness possible |

| Applications | Construction, infrastructure, automotive parts | Aerospace, energy, chemical storage tanks |

Introduction to Composite Manufacturing Processes

Pultrusion and filament winding are key composite manufacturing processes used to create high-strength, lightweight components. Pultrusion involves pulling continuous fibers through a resin bath and shaping them in a heated die for constant cross-section profiles, ideal for structural parts with uniform geometry. Filament winding wraps resin-impregnated fibers around a rotating mandrel, producing hollow, cylindrical structures with excellent strength-to-weight ratios for pressure vessels and pipes.

Understanding Pultrusion: Process and Applications

Pultrusion is a continuous manufacturing process that pulls fibers through a resin bath and into a heated die, creating strong, lightweight composite profiles with consistent cross-sections. Common applications include structural components in construction, automotive parts, and electrical insulators due to its high fiber volume fraction and excellent mechanical properties. This process offers precise dimensional control and cost efficiency ideal for high-volume production of standardized composite shapes.

Overview of Filament Winding Technology

Filament winding technology involves the precise application of continuous fibers, such as carbon or glass, impregnated with resin, onto a rotating mandrel to form strong, lightweight composite structures. This automated process enables high fiber volume fractions and optimized fiber orientation, resulting in superior mechanical properties ideal for pressure vessels, pipes, and aerospace components. Compared to pultrusion, filament winding offers greater flexibility in producing complex shapes and varying thicknesses, enhancing design versatility and performance in composite manufacturing.

Key Differences Between Pultrusion and Filament Winding

Pultrusion produces continuous, constant cross-section profiles by pulling fibers through a resin bath and heated die, while filament winding wraps resin-impregnated fibers around a rotating mandrel layer by layer to form hollow, cylindrical shapes. Pultrusion offers high production speed and dimensional accuracy for flat or linear parts, whereas filament winding excels in creating complex, hollow structures with superior fiber orientation control. Pultrusion is ideal for structural profiles like beams and rods, while filament winding is preferred for pressure vessels, pipes, and tanks requiring high strength-to-weight ratios.

Material Compatibility in Pultrusion vs Filament Winding

Pultrusion is highly compatible with continuous fiber reinforcements like glass, carbon, and aramid fibers, allowing precise control over fiber alignment for enhanced mechanical properties. Filament winding excels in wrapping fibers around complex geometries using materials such as glass, carbon, and hybrid fibers, optimizing strength and stiffness in cylindrical or round composite structures. Material compatibility in pultrusion favors linear fiber arrangements, while filament winding supports diverse fiber orientations to meet specific structural requirements.

Structural Properties: Strength, Flexibility, and Durability

Pultrusion offers superior tensile strength and consistent cross-sectional profiles ideal for load-bearing structural components, while filament winding excels in creating high-strength, lightweight cylindrical shapes with enhanced fiber orientation control. Pultruded composites provide excellent rigidity and dimensional stability, making them suitable for applications requiring stiffness, whereas filament-wound composites demonstrate greater flexibility and impact resistance due to their layered fiber architecture. Both methods deliver exceptional durability, but filament winding typically achieves better fatigue resistance and corrosion protection, essential for demanding structural environments.

Cost Analysis: Pultrusion vs Filament Winding

Pultrusion offers lower initial tooling and setup costs compared to filament winding, making it more cost-effective for high-volume production of constant cross-section composite profiles. Filament winding involves higher labor and equipment expenses due to its complex, customizable process but provides superior strength-to-weight ratios for cylindrical components. While pultrusion minimizes material waste through continuous processing, filament winding's variable material application can lead to higher raw material consumption and costs.

Design Flexibility and Limitations

Pultrusion offers high precision for constant cross-section profiles but limits design flexibility due to its linear process and fixed tooling. Filament winding allows complex, variable geometry parts with excellent fiber orientation control, ideal for cylindrical or curved structures. However, filament winding's intricate setup and slower production rates restrict its suitability for high-volume, uniform cross-section components.

Typical Applications in Industry

Pultrusion is commonly used in producing structural components such as ladder rails, window frames, and electrical insulators due to its ability to create constant cross-section profiles with high fiber volume. Filament winding excels in manufacturing cylindrical or spherical shapes like pressure vessels, pipes, and aerospace fuel tanks because it provides superior strength through controlled fiber orientation. Both processes serve critical roles in aerospace, automotive, and construction industries, with pultrusion offering cost-effective linear parts and filament winding delivering high-performance rotational components.

Choosing the Right Process for Your Composite Needs

Pultrusion offers high production rates and consistent cross-sectional profiles ideal for structural applications requiring uniform strength and rigidity. Filament winding excels in creating complex, cylindrical shapes with superior fiber alignment, maximizing strength-to-weight ratios in pressure vessels and pipes. Selecting between pultrusion and filament winding depends on product geometry, mechanical performance requirements, and production volume constraints to ensure optimal composite material performance.

Pultrusion vs Filament Winding Infographic

materialdif.com

materialdif.com