3D weaving integrates fibers in multiple directions, creating complex, thick textile structures that significantly enhance mechanical properties such as strength and impact resistance. Unlike 2D weaving, which produces flat fabrics with fibers predominantly oriented in two directions, 3D woven composites offer superior dimensional stability and damage tolerance. These advancements make 3D woven materials ideal for aerospace, automotive, and protective applications where structural integrity is critical.

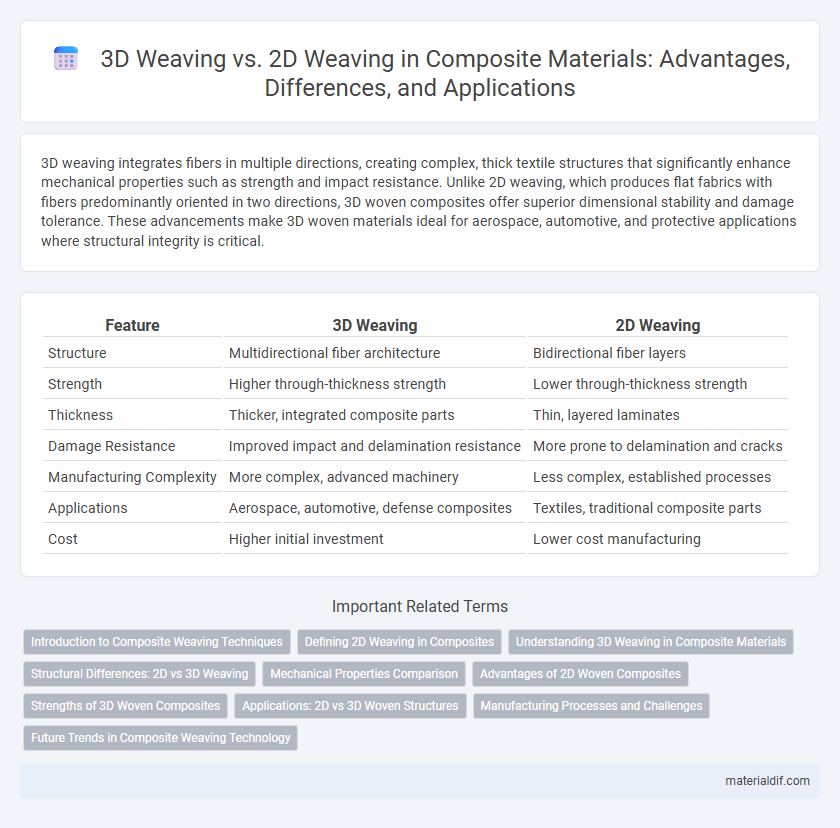

Table of Comparison

| Feature | 3D Weaving | 2D Weaving |

|---|---|---|

| Structure | Multidirectional fiber architecture | Bidirectional fiber layers |

| Strength | Higher through-thickness strength | Lower through-thickness strength |

| Thickness | Thicker, integrated composite parts | Thin, layered laminates |

| Damage Resistance | Improved impact and delamination resistance | More prone to delamination and cracks |

| Manufacturing Complexity | More complex, advanced machinery | Less complex, established processes |

| Applications | Aerospace, automotive, defense composites | Textiles, traditional composite parts |

| Cost | Higher initial investment | Lower cost manufacturing |

Introduction to Composite Weaving Techniques

3D weaving produces integrated fiber architectures by interlacing fibers in three dimensions, enhancing mechanical properties like impact resistance and delamination strength compared to traditional 2D weaving, which interlaces fibers only in two dimensions. The 3D woven composites enable complex shapes and thickness variations, offering superior structural performance for aerospace and automotive applications. Advances in composite weaving techniques have led to optimized fiber volume fractions and improved load distribution, making 3D weaving a vital innovation in composite manufacturing.

Defining 2D Weaving in Composites

2D weaving in composites involves interlacing fibers in two perpendicular directions, typically forming warp and weft layers that provide strength and stability in a flat plane. This method produces fabrics that are primarily designed to resist loads within the fabric plane but offer limited through-thickness reinforcement. Common 2D woven composites are utilized in applications requiring high in-plane mechanical properties, such as automotive panels and aerospace skin structures.

Understanding 3D Weaving in Composite Materials

3D weaving in composite materials integrates fibers in multiple directions, enhancing structural integrity and load distribution compared to traditional 2D weaving, which aligns fibers only in two perpendicular planes. This multidirectional fiber arrangement in 3D woven composites improves resistance to delamination, impact, and fatigue, making them ideal for aerospace, automotive, and defense applications. Advanced 3D weaving techniques enable the production of complex shapes with superior mechanical properties and reduced manufacturing defects.

Structural Differences: 2D vs 3D Weaving

3D weaving integrates fibers in multiple directions, creating a unified, multi-dimensional architecture that significantly enhances mechanical properties such as impact resistance and delamination strength compared to traditional 2D weaving, which layers fibers primarily in two orthogonal directions. Unlike 2D weaving that produces flat textile sheets, 3D weaving utilizes interlacing in the thickness direction, resulting in composite preforms with improved load distribution and structural integrity. These differences enable 3D woven composites to outperform 2D counterparts in aerospace and automotive applications requiring superior strength-to-weight ratios and damage tolerance.

Mechanical Properties Comparison

3D weaving significantly enhances mechanical properties compared to 2D weaving by providing superior through-thickness strength and improved delamination resistance due to its integrated fiber architecture. The interlaced fibers in 3D woven composites distribute loads more evenly, resulting in higher impact toughness and better fatigue performance. In contrast, 2D woven composites primarily exhibit strength and stiffness in plane directions while being prone to weakness in thickness, limiting their structural applications in high-performance composites.

Advantages of 2D Woven Composites

2D woven composites offer enhanced fabric stability and uniform thickness, which results in predictable mechanical performance ideal for aerospace and automotive applications. The simpler manufacturing process of 2D weaving ensures cost-effectiveness and high production speed, benefiting large-scale composite part fabrication. Their excellent in-plane strength and ease of integration with thermoset and thermoplastic matrices make 2D woven composites a versatile choice for structural components.

Strengths of 3D Woven Composites

3D woven composites exhibit superior interlaminar shear strength and enhanced damage tolerance compared to traditional 2D woven composites, due to their integrated fiber architecture that reinforces through-the-thickness properties. Their complex fiber interlacing offers improved impact resistance and resistance to delamination, making them ideal for aerospace and automotive structural applications. The enhanced mechanical performance of 3D woven composites enables lightweight designs with increased durability and reliability in high-stress environments.

Applications: 2D vs 3D Woven Structures

3D woven structures offer enhanced mechanical properties such as improved impact resistance, through-thickness strength, and damage tolerance, making them ideal for aerospace, automotive, and defense applications. In contrast, 2D woven fabrics are commonly used in traditional textile composites where planar strength and stiffness suffice, such as in sporting goods and marine components. The ability of 3D weaving to integrate multiple layers into a single preform optimizes structural integrity and reduces manufacturing complexity compared to separate layering in 2D composites.

Manufacturing Processes and Challenges

3D weaving integrates multiple yarn layers through interlacing in three dimensions, creating seamless composite structures with enhanced mechanical properties, while 2D weaving arranges yarns in two perpendicular planes, resulting in layered fabrics requiring subsequent stacking and bonding. Manufacturing 3D woven composites involves complex loom configurations and precise control of yarn tension, posing challenges in machine design and process optimization. Conversely, 2D weaving benefits from established, simpler machinery but faces limitations in out-of-plane strength and requires additional bonding steps to achieve comparable composite performance.

Future Trends in Composite Weaving Technology

Future trends in composite weaving technology emphasize the advancement of 3D weaving due to its superior mechanical properties and structural integrity compared to traditional 2D weaving. Innovations in multi-axial fiber placement and automated loom technology enable complex geometries and enhanced load distribution within composite materials. These developments drive increased adoption in aerospace, automotive, and sporting goods industries, where lightweight and high-strength components are critical.

3D Weaving vs 2D Weaving Infographic

materialdif.com

materialdif.com