Vacuum bagging offers superior consolidation and resin distribution compared to hand lay-up, resulting in stronger, lighter composite parts with fewer voids. While hand lay-up is simpler and more cost-effective for small-scale projects, vacuum bagging enhances component quality by applying uniform pressure during curing. This method reduces excess resin and improves fiber-to-resin ratio, critical for high-performance composite applications.

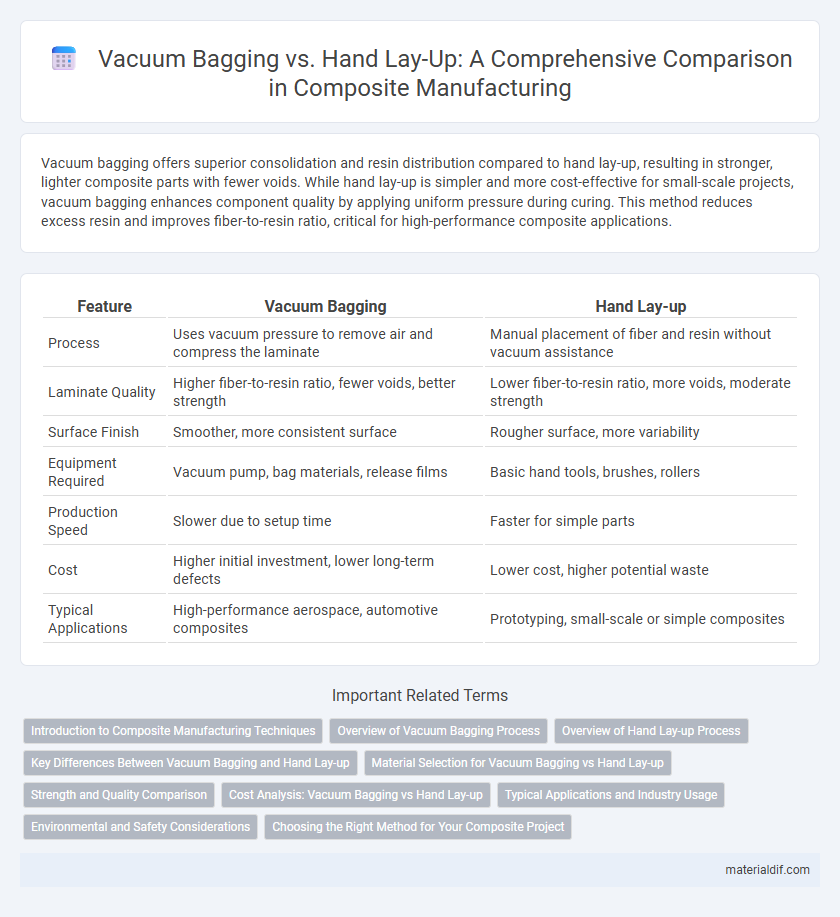

Table of Comparison

| Feature | Vacuum Bagging | Hand Lay-up |

|---|---|---|

| Process | Uses vacuum pressure to remove air and compress the laminate | Manual placement of fiber and resin without vacuum assistance |

| Laminate Quality | Higher fiber-to-resin ratio, fewer voids, better strength | Lower fiber-to-resin ratio, more voids, moderate strength |

| Surface Finish | Smoother, more consistent surface | Rougher surface, more variability |

| Equipment Required | Vacuum pump, bag materials, release films | Basic hand tools, brushes, rollers |

| Production Speed | Slower due to setup time | Faster for simple parts |

| Cost | Higher initial investment, lower long-term defects | Lower cost, higher potential waste |

| Typical Applications | High-performance aerospace, automotive composites | Prototyping, small-scale or simple composites |

Introduction to Composite Manufacturing Techniques

Vacuum bagging enhances composite manufacturing by applying uniform pressure to layers, improving fiber-to-resin ratio and reducing voids compared to hand lay-up. Hand lay-up involves manually placing fibers and resin, making it simpler but often resulting in lower strength and quality. This method suits small-scale or prototype production, while vacuum bagging is preferred for high-performance, structurally critical components.

Overview of Vacuum Bagging Process

Vacuum bagging is a composite manufacturing process that uses a vacuum to compress layers of fiber and resin, ensuring uniform laminate thickness and improved fiber-to-resin ratio. The process involves placing the composite lay-up inside a sealed bag, then applying vacuum pressure to remove air and excess resin, enhancing consolidation and reducing voids. Vacuum bagging offers superior mechanical properties and surface finish compared to hand lay-up, making it ideal for high-performance composite structures.

Overview of Hand Lay-up Process

The hand lay-up process involves manually placing reinforcement fibers into a mold and applying resin to create composite structures. This method allows precise control over fiber orientation and resin distribution, making it suitable for producing large, complex shapes. Although labor-intensive and slower than vacuum bagging, hand lay-up remains cost-effective for low-volume or prototype composites manufacturing.

Key Differences Between Vacuum Bagging and Hand Lay-up

Vacuum bagging uses a sealed bag and vacuum pressure to compact composite layers, resulting in superior fiber-to-resin ratios and reduced voids. Hand lay-up relies on manual resin application and air pressure, often leading to lower structural integrity and higher variability. Vacuum bagging offers enhanced mechanical properties and consistent quality compared to the more labor-intensive, less precise hand lay-up process.

Material Selection for Vacuum Bagging vs Hand Lay-up

Vacuum bagging typically requires compatible materials such as peel ply, breather fabric, and vacuum bags designed to withstand pressure and temperature variations, enhancing resin flow and consolidation. Hand lay-up allows for more flexibility in material choice, often using basic release films and less specialized fabrics, making it suitable for lower precision applications but with less control over resin distribution. Selecting materials specifically engineered for vacuum bagging improves composite strength and consistency compared to the more manual approach in hand lay-up processes.

Strength and Quality Comparison

Vacuum bagging produces composite parts with higher fiber-to-resin ratios, resulting in superior strength and improved mechanical properties compared to hand lay-up. The controlled pressure during vacuum bagging eliminates air voids, enhancing laminate quality and reducing defects commonly found in hand lay-up methods. Consequently, vacuum bagging offers more consistent and durable composite structures ideal for aerospace and automotive applications.

Cost Analysis: Vacuum Bagging vs Hand Lay-up

Vacuum bagging typically incurs higher upfront costs due to specialized equipment such as vacuum pumps, bags, and sealants, but it offers superior resin control and reduced waste, which can lower overall material expenses. In contrast, hand lay-up requires minimal tooling investment and labor costs are variable depending on skill level, making it more cost-effective for small-scale or low-volume production. Long-term cost efficiency favors vacuum bagging as it enhances composite quality, reduces rework, and accelerates curing times, leading to better return on investment in larger production runs.

Typical Applications and Industry Usage

Vacuum bagging is widely used in aerospace and marine industries for high-performance composite parts, offering superior resin control and reduced void content critical for structural integrity. Hand lay-up remains prevalent in automotive prototypes and small-scale manufacturing due to its cost-effectiveness and suitability for simple geometries. Both methods serve distinct industry needs, with vacuum bagging preferred for demanding applications requiring high strength-to-weight ratios and hand lay-up favored for rapid, low-volume production.

Environmental and Safety Considerations

Vacuum bagging significantly reduces volatile organic compound (VOC) emissions by minimizing resin exposure compared to hand lay-up, enhancing workplace air quality and environmental safety. This technique lowers the risk of operator contact with hazardous chemicals, decreasing potential skin irritation and respiratory issues prevalent in traditional hand lay-up methods. The sealed environment in vacuum bagging also limits waste generation and disposal challenges associated with excess resin and consumables, promoting a more sustainable composite manufacturing process.

Choosing the Right Method for Your Composite Project

Vacuum bagging offers superior consolidation and reduced void content, making it ideal for high-performance composite projects requiring enhanced strength and surface finish. Hand lay-up provides a cost-effective and versatile option suited for simpler shapes and lower production volumes. Selecting the right method depends on project complexity, budget constraints, and desired mechanical properties.

Vacuum Bagging vs Hand Lay-up Infographic

materialdif.com

materialdif.com