Sandwich panels consist of a lightweight core material bonded between two outer layers, offering superior strength-to-weight ratio and excellent thermal insulation. Laminates are created by bonding multiple layers of similar or different materials, providing enhanced durability and resistance to wear and impact. Choosing between sandwich panels and laminates depends on specific application requirements such as structural performance, weight constraints, and environmental resistance.

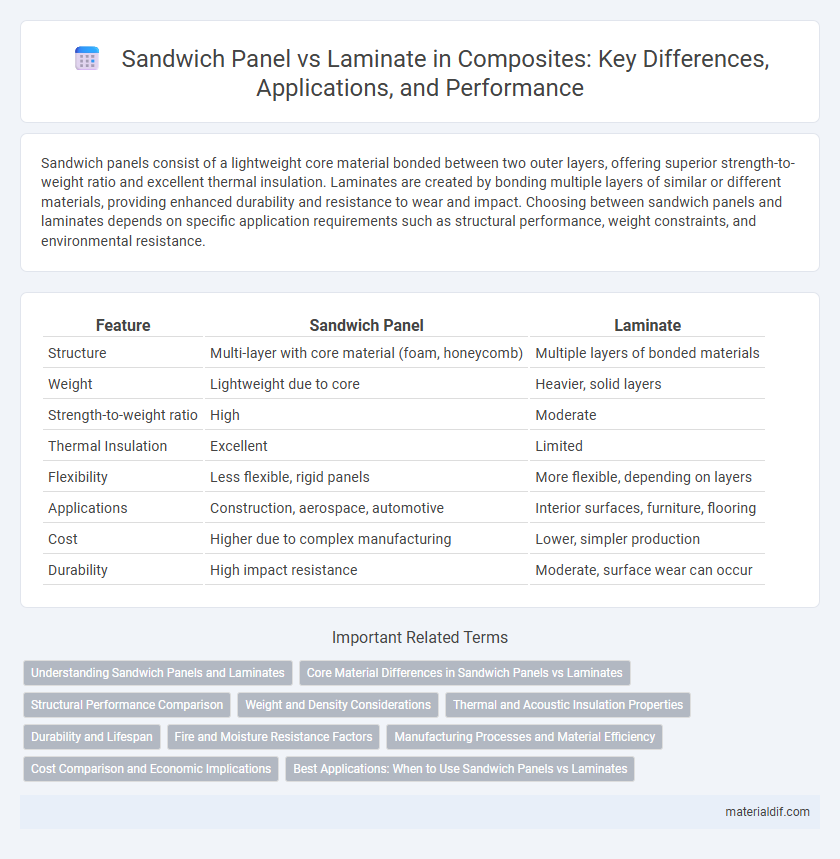

Table of Comparison

| Feature | Sandwich Panel | Laminate |

|---|---|---|

| Structure | Multi-layer with core material (foam, honeycomb) | Multiple layers of bonded materials |

| Weight | Lightweight due to core | Heavier, solid layers |

| Strength-to-weight ratio | High | Moderate |

| Thermal Insulation | Excellent | Limited |

| Flexibility | Less flexible, rigid panels | More flexible, depending on layers |

| Applications | Construction, aerospace, automotive | Interior surfaces, furniture, flooring |

| Cost | Higher due to complex manufacturing | Lower, simpler production |

| Durability | High impact resistance | Moderate, surface wear can occur |

Understanding Sandwich Panels and Laminates

Sandwich panels consist of two strong outer layers bonded to a lightweight core, offering high stiffness-to-weight ratios ideal for aerospace and construction applications. Laminates are composed of multiple bonded layers of similar or different materials, enhancing strength and flexibility in designs such as automotive components and sports equipment. Understanding these structures' distinct composition and mechanical properties is crucial for selecting the appropriate composite system based on load requirements and environmental conditions.

Core Material Differences in Sandwich Panels vs Laminates

The core material in sandwich panels typically consists of lightweight foams such as polyurethane, polystyrene, or honeycomb structures like aluminum or aramid, providing high stiffness-to-weight ratios and improved thermal insulation. In contrast, laminates generally lack a distinct core, relying instead on multiple bonded composite layers, such as carbon or glass fiber-reinforced polymers, which emphasize surface strength and durability rather than lightweight core properties. This fundamental difference results in sandwich panels offering superior load distribution and energy absorption, whereas laminates are optimized for surface hardness and impact resistance.

Structural Performance Comparison

Sandwich panels exhibit superior structural performance compared to laminates due to their high stiffness-to-weight ratio, achieved by combining lightweight core materials such as foam or honeycomb with strong face sheets. This configuration provides excellent flexural rigidity and impact resistance, making sandwich panels ideal for load-bearing applications where weight reduction is critical. In contrast, laminates, composed of stacked fiber-reinforced layers, offer good strength and durability but generally lack the enhanced bending stiffness and energy absorption capabilities of sandwich constructions.

Weight and Density Considerations

Sandwich panels typically offer superior weight reduction compared to laminates due to their core materials, such as foam or honeycomb, which significantly lower density without compromising structural integrity. Laminate composites have a higher density, as they consist of multiple layers of fiber-reinforced resin matrices, leading to increased weight per unit volume. Choosing sandwich panels over laminates is advantageous in applications requiring lightweight construction combined with high stiffness-to-weight ratios.

Thermal and Acoustic Insulation Properties

Sandwich panels offer superior thermal insulation due to their core materials, such as polyurethane or polystyrene foam, which provide low thermal conductivity, reducing energy loss in buildings. In contrast, laminates generally have higher density and lower insulating properties, making them less effective for thermal regulation. For acoustic insulation, sandwich panels excel by combining rigid face sheets with absorbent core layers, effectively dampening sound transmission compared to traditional laminate materials.

Durability and Lifespan

Sandwich panels exhibit superior durability compared to laminates due to their multi-layered structure, which combines a lightweight core with strong outer skins to resist impact, moisture, and environmental degradation. The lifespan of sandwich panels typically exceeds that of laminates, often lasting 30-40 years in construction applications, while laminates may degrade faster under similar conditions due to their homogeneous composition. Enhanced mechanical properties and improved resistance to wear and corrosion make sandwich panels a preferred choice for long-term performance in building and industrial uses.

Fire and Moisture Resistance Factors

Sandwich panels offer superior fire resistance due to their core materials like mineral wool or fire-retardant foam, which provide effective thermal insulation and slow flame spread. Laminate composites typically show less moisture resistance as they can absorb water through resin cracks or fiber interfaces, leading to delamination and reduced structural integrity. In contrast, sandwich panels feature sealed edges and impermeable outer skins, significantly enhancing moisture resistance and durability in harsh environments.

Manufacturing Processes and Material Efficiency

Sandwich panels feature a core material bonded between two face sheets, typically manufactured through processes like foam or honeycomb core insertion and adhesive bonding, optimizing material usage by combining lightweight cores with high-strength skins. Laminate composites are produced by layering fiber-reinforced plies, often employing techniques such as hand lay-up, vacuum bagging, or automated fiber placement to maximize fiber alignment and resin distribution, enhancing mechanical properties and minimizing waste. Sandwich panels generally achieve superior material efficiency in structural applications by reducing weight while maintaining rigidity, whereas laminates offer versatility in thickness and shape with precise fiber orientation control.

Cost Comparison and Economic Implications

Sandwich panels generally offer a more cost-effective solution compared to laminates due to their lightweight core materials like foam or honeycomb, which reduce material usage and transportation expenses. Laminate composites often require more expensive resins and fiber reinforcements, increasing upfront costs and limiting scalability for large projects. Evaluating long-term economic implications, sandwich panels also contribute to lower installation and maintenance costs, making them preferable for budget-sensitive applications requiring structural efficiency.

Best Applications: When to Use Sandwich Panels vs Laminates

Sandwich panels are ideal for applications requiring high strength-to-weight ratios and thermal insulation, such as aerospace, automotive, and construction industries. Laminates excel in environments demanding superior surface finish, durability, and electrical insulation, commonly used in electronics and decorative surfaces. Choosing between sandwich panels and laminates depends on structural requirements, weight constraints, and specific environmental conditions.

Sandwich Panel vs Laminate Infographic

materialdif.com

materialdif.com