Resin Transfer Molding (RTM) offers superior precision and consistency compared to hand layup, producing composites with higher strength-to-weight ratios and less porosity. Hand layup remains popular for its low cost and simplicity in small-scale or custom applications, despite higher labor intensity and variability in part quality. RTM automation enhances repeatability and reduces waste, making it ideal for high-volume manufacturing of complex composite components.

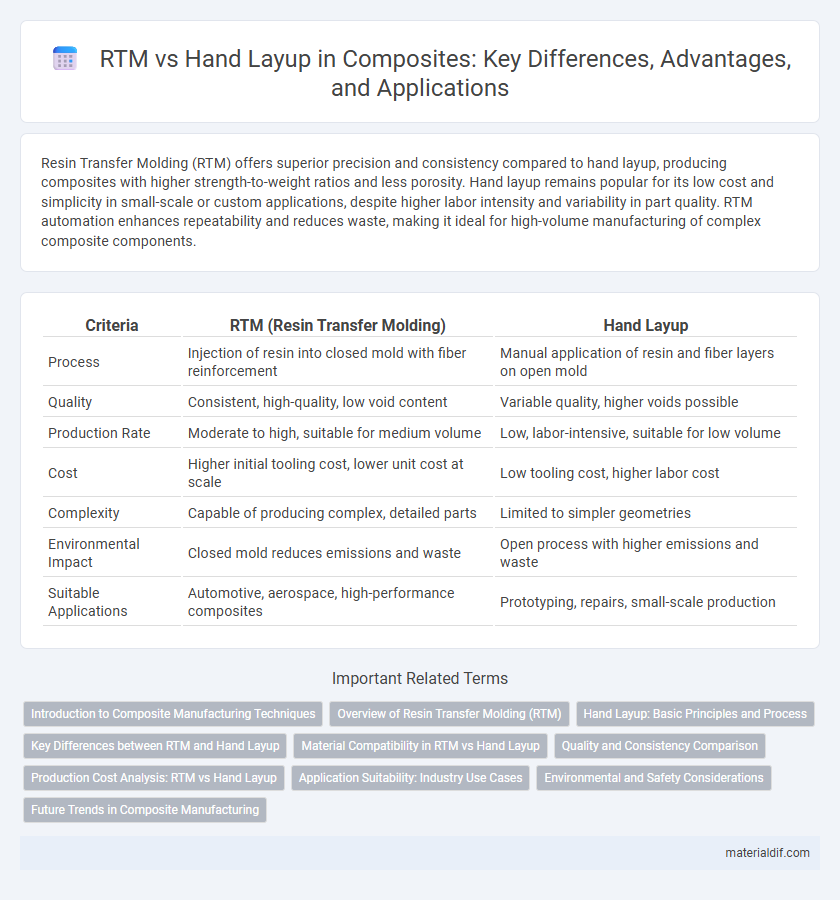

Table of Comparison

| Criteria | RTM (Resin Transfer Molding) | Hand Layup |

|---|---|---|

| Process | Injection of resin into closed mold with fiber reinforcement | Manual application of resin and fiber layers on open mold |

| Quality | Consistent, high-quality, low void content | Variable quality, higher voids possible |

| Production Rate | Moderate to high, suitable for medium volume | Low, labor-intensive, suitable for low volume |

| Cost | Higher initial tooling cost, lower unit cost at scale | Low tooling cost, higher labor cost |

| Complexity | Capable of producing complex, detailed parts | Limited to simpler geometries |

| Environmental Impact | Closed mold reduces emissions and waste | Open process with higher emissions and waste |

| Suitable Applications | Automotive, aerospace, high-performance composites | Prototyping, repairs, small-scale production |

Introduction to Composite Manufacturing Techniques

Resin Transfer Molding (RTM) and Hand Layup are prominent composite manufacturing techniques used for producing high-strength, lightweight components. RTM offers precise fiber placement and resin infusion within a closed mold, resulting in superior surface finish and reduced void content compared to the more labor-intensive Hand Layup process. Hand Layup remains popular for low-volume production and prototyping due to its simplicity and minimal equipment requirements.

Overview of Resin Transfer Molding (RTM)

Resin Transfer Molding (RTM) is a closed-mold composite manufacturing process where resin is injected into a mold containing a fiber preform, ensuring high precision and repeatability. Compared to hand layup, RTM offers superior surface finish, dimensional accuracy, and reduced volatile emissions due to its controlled environment. This process is widely used for producing complex, high-performance composite parts with enhanced mechanical properties and consistent quality.

Hand Layup: Basic Principles and Process

Hand layup is a fundamental composite manufacturing technique involving the manual layering of reinforcement fibers, such as fiberglass or carbon fiber, onto a mold surface followed by the application of resin. This process ensures precise control over fiber orientation and resin distribution, enhancing the structural integrity and surface finish of the final part. Typically used for low-volume production and large, complex shapes, hand layup offers cost-effective flexibility compared to Resin Transfer Molding (RTM) techniques.

Key Differences between RTM and Hand Layup

RTM (Resin Transfer Molding) offers higher precision and repeatability compared to Hand Layup, which relies on manual application and can result in variable quality. RTM provides superior resin control and reduces porosity, leading to stronger, more consistent composite parts, while Hand Layup is labor-intensive with longer curing times. RTM's closed mold process enhances surface finish and environmental safety, unlike the open mold technique used in Hand Layup.

Material Compatibility in RTM vs Hand Layup

Resin Transfer Molding (RTM) offers superior material compatibility by enabling precise control over resin flow and fiber impregnation, resulting in consistent composite quality and reduced void content compared to Hand Layup. Hand Layup often struggles with uniform resin distribution, making it less suitable for complex or high-performance materials that require exact resin-to-fiber ratios. RTM's closed mold environment also minimizes contamination and allows for a wider range of thermosetting and thermoplastic resins to be effectively processed.

Quality and Consistency Comparison

RTM (Resin Transfer Molding) offers superior quality and consistency compared to hand layup due to its closed mold process, which ensures uniform resin distribution and minimizes voids. The controlled environment in RTM reduces human error and enhances repeatability, leading to higher structural integrity and surface finish quality. Hand layup, being labor-intensive and open to environmental variables, often results in greater variability in fiber placement and resin content, affecting overall part strength and consistency.

Production Cost Analysis: RTM vs Hand Layup

Resin Transfer Molding (RTM) significantly reduces production costs compared to Hand Layup by minimizing material waste and enabling faster cycle times. RTM's closed mold process lowers labor expenses and enhances repeatability, resulting in consistent quality and decreased rework. In contrast, Hand Layup demands higher manual labor intensity and material usage, driving up overall manufacturing costs.

Application Suitability: Industry Use Cases

Resin Transfer Molding (RTM) is ideal for high-volume automotive and aerospace components due to its precision and repeatability, enabling complex shapes with superior mechanical properties. Hand Layup excels in low-volume marine and custom fabrication projects where flexibility and cost-effectiveness for small batches are critical. RTM's controlled process suits industrial applications requiring tight tolerances, whereas Hand Layup supports prototyping and repair work across diverse industries.

Environmental and Safety Considerations

RTM (Resin Transfer Molding) offers superior environmental benefits compared to hand layup by reducing volatile organic compound (VOC) emissions and minimizing resin waste through closed molding processes. Hand layup exposes operators to higher levels of hazardous fumes and particulate matter, increasing health risks and necessitating extensive ventilation and personal protective equipment. RTM's controlled environment enhances workplace safety by limiting operator contact with uncured resins and fibers, aligning with stricter environmental regulations and occupational safety standards.

Future Trends in Composite Manufacturing

Resin Transfer Molding (RTM) is increasingly favored over traditional Hand Layup due to its automation potential and superior fiber-to-resin ratio, driving efficiency in composite manufacturing. Future trends highlight the integration of advanced sensors and AI-driven process controls in RTM, enhancing precision and reducing waste. Sustainable materials and faster cycle times are also shaping the shift toward RTM, meeting demand for eco-friendly, high-performance composites in automotive and aerospace industries.

RTM vs Hand Layup Infographic

materialdif.com

materialdif.com