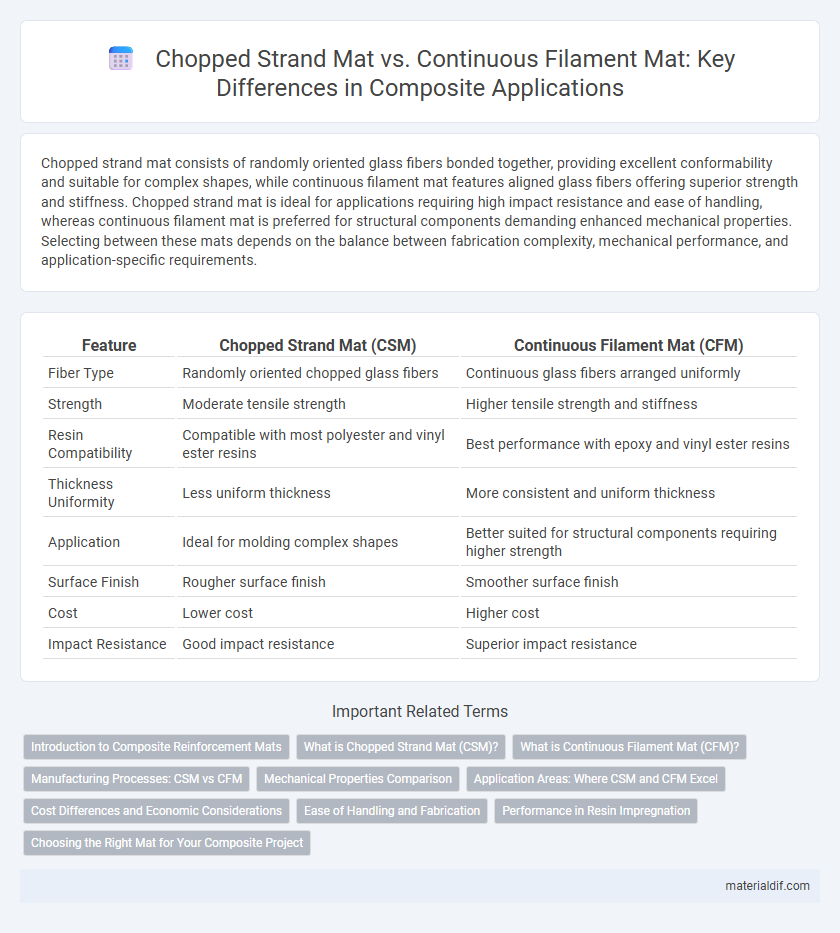

Chopped strand mat consists of randomly oriented glass fibers bonded together, providing excellent conformability and suitable for complex shapes, while continuous filament mat features aligned glass fibers offering superior strength and stiffness. Chopped strand mat is ideal for applications requiring high impact resistance and ease of handling, whereas continuous filament mat is preferred for structural components demanding enhanced mechanical properties. Selecting between these mats depends on the balance between fabrication complexity, mechanical performance, and application-specific requirements.

Table of Comparison

| Feature | Chopped Strand Mat (CSM) | Continuous Filament Mat (CFM) |

|---|---|---|

| Fiber Type | Randomly oriented chopped glass fibers | Continuous glass fibers arranged uniformly |

| Strength | Moderate tensile strength | Higher tensile strength and stiffness |

| Resin Compatibility | Compatible with most polyester and vinyl ester resins | Best performance with epoxy and vinyl ester resins |

| Thickness Uniformity | Less uniform thickness | More consistent and uniform thickness |

| Application | Ideal for molding complex shapes | Better suited for structural components requiring higher strength |

| Surface Finish | Rougher surface finish | Smoother surface finish |

| Cost | Lower cost | Higher cost |

| Impact Resistance | Good impact resistance | Superior impact resistance |

Introduction to Composite Reinforcement Mats

Chopped Strand Mat (CSM) consists of randomly oriented short glass fibers held together by a binder, providing isotropic strength ideal for molding complex shapes in composites. Continuous Filament Mat (CFM) features continuous glass fibers aligned in specific directions, offering superior tensile strength and stiffness along those axes. Both reinforcement mats enhance composite performance by improving mechanical properties, durability, and dimensional stability in applications such as automotive, marine, and construction industries.

What is Chopped Strand Mat (CSM)?

Chopped Strand Mat (CSM) is a type of reinforcement in composite materials made from randomly oriented glass fiber strands bound together with a binder, primarily used to enhance strength and impact resistance in fiberglass laminates. Its isotropic properties ensure uniform strength distribution, making it ideal for applications requiring consistent mechanical performance, such as boat hulls, automotive panels, and corrosion-resistant tanks. Compared to Continuous Filament Mat, CSM offers easier handling and better conformity to complex shapes, though with slightly lower tensile strength and stiffness.

What is Continuous Filament Mat (CFM)?

Continuous Filament Mat (CFM) is a type of reinforcing material used in composite manufacturing, consisting of long, unbroken glass fibers arranged in a random or oriented pattern to enhance strength and durability. Unlike Chopped Strand Mat, which uses short glass fibers, CFM offers improved mechanical properties and better resin distribution due to its continuous fibers. This makes CFM ideal for applications requiring high tensile strength, impact resistance, and excellent surface finish in composites such as automotive parts, boat hulls, and aerospace components.

Manufacturing Processes: CSM vs CFM

Chopped Strand Mat (CSM) manufacturing involves randomly orienting short fiberglass strands, which are chopped and sprayed onto a carrier to form a quick wet-out mat ideal for molding complex shapes. Continuous Filament Mat (CFM) production utilizes longer, continuous glass fibers aligned within the mat, creating improved mechanical properties and better resin flow control during composite fabrication. The differences in strand length and fiber orientation between CSM and CFM directly impact drapability, mechanical strength, and the resin infusion process efficiency.

Mechanical Properties Comparison

Chopped Strand Mat (CSM) offers improved impact resistance and better conformability to complex shapes compared to Continuous Filament Mat (CFM), which provides superior tensile strength and stiffness due to its aligned fibers. CSM composites generally exhibit lower tensile and flexural modulus but higher elongation at break, making them suitable for applications requiring toughness rather than rigidity. The mechanical properties of CFM reinforce superior load transfer and fatigue resistance, ideal for structural components demanding high performance and durability.

Application Areas: Where CSM and CFM Excel

Chopped Strand Mat (CSM) excels in applications requiring isotropic strength and rapid molding, such as boat hulls, automotive parts, and surfboards, where its random fiber orientation enhances impact resistance. Continuous Filament Mat (CFM) is preferred in areas demanding higher tensile strength and structural integrity, including wind turbine blades, aerospace components, and high-performance sporting goods. The choice between CSM and CFM hinges on the specific mechanical properties needed and the complexity of the composite's shape.

Cost Differences and Economic Considerations

Chopped strand mat is generally more cost-effective than continuous filament mat due to its simpler manufacturing process and lower raw material expenses. Continuous filament mat offers higher strength and durability, which can lead to long-term economic benefits in structural applications despite its higher initial price. Evaluating total lifecycle costs and application requirements is crucial for making an informed economic decision between the two composite reinforcements.

Ease of Handling and Fabrication

Chopped Strand Mat (CSM) offers superior ease of handling due to its loose, non-woven structure that conforms readily to complex shapes, making it ideal for quick and flexible fabrication processes. Continuous Filament Mat (CFM), composed of aligned fiber strands, provides enhanced mechanical properties but requires more precise handling and cutting techniques, increasing fabrication complexity. Manufacturers often prefer CSM for rapid, less labor-intensive applications, while CFM is selected when structural integrity and strength dictate fabrication priorities.

Performance in Resin Impregnation

Chopped Strand Mat offers faster resin impregnation due to its open and random fiber structure, promoting superior wet-out and reduced air entrapment. Continuous Filament Mat, with aligned fibers, provides higher mechanical strength but requires longer resin flow times for full saturation, potentially impacting production speed. Optimizing resin viscosity and processing parameters is crucial to balance impregnation quality and performance benefits for each mat type in composite manufacturing.

Choosing the Right Mat for Your Composite Project

Choosing the right mat for your composite project depends on the desired strength and surface finish. Chopped strand mat offers excellent uniformity and is ideal for complex shapes, providing good mechanical properties and ease of handling. Continuous filament mat delivers higher tensile strength and improved impact resistance, making it suitable for applications requiring superior durability and structural performance.

Chopped Strand Mat vs Continuous Filament Mat Infographic

materialdif.com

materialdif.com