The open mold process involves layering composite materials in an open cavity, allowing for easy customization but often resulting in higher emissions and less consistent part quality. The closed mold process encloses the composite materials between two molds, providing better control of resin flow, improved surface finish, and reduced environmental impact. Choosing between these methods depends on production volume, part complexity, and quality requirements.

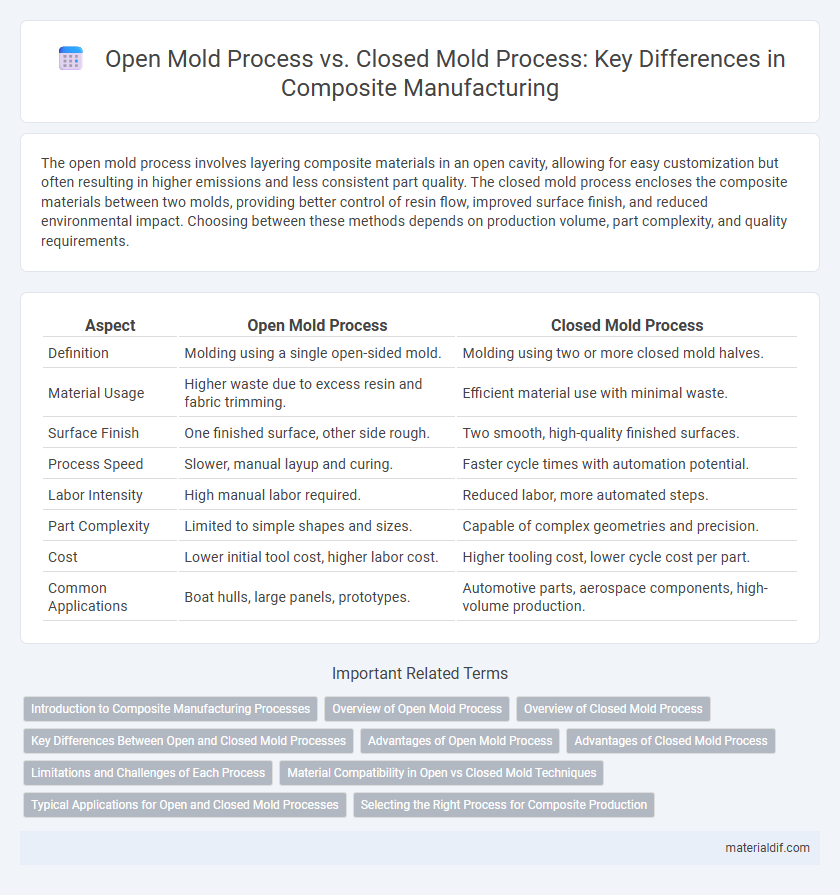

Table of Comparison

| Aspect | Open Mold Process | Closed Mold Process |

|---|---|---|

| Definition | Molding using a single open-sided mold. | Molding using two or more closed mold halves. |

| Material Usage | Higher waste due to excess resin and fabric trimming. | Efficient material use with minimal waste. |

| Surface Finish | One finished surface, other side rough. | Two smooth, high-quality finished surfaces. |

| Process Speed | Slower, manual layup and curing. | Faster cycle times with automation potential. |

| Labor Intensity | High manual labor required. | Reduced labor, more automated steps. |

| Part Complexity | Limited to simple shapes and sizes. | Capable of complex geometries and precision. |

| Cost | Lower initial tool cost, higher labor cost. | Higher tooling cost, lower cycle cost per part. |

| Common Applications | Boat hulls, large panels, prototypes. | Automotive parts, aerospace components, high-volume production. |

Introduction to Composite Manufacturing Processes

Open mold process in composite manufacturing involves layering reinforcement materials over an open tool and manually applying resin, enabling lower tooling costs and flexibility for large or complex shapes. Closed mold process encapsulates the reinforcement materials within two matched molds, allowing better control over resin distribution, improved surface finish, and higher structural integrity in the final composite part. Each process offers distinct advantages depending on requirements like production volume, mechanical properties, and cost efficiency in composite manufacturing.

Overview of Open Mold Process

The Open Mold Process involves fabricating composite parts by layering reinforcement materials directly onto a single mold surface exposed to the environment, facilitating easy access for manual fabrication and inspection. This method typically uses hand lay-up or spray-up techniques, making it cost-effective and suitable for large, simple geometries with lower production volumes. The open mold approach allows for flexibility in material placement but may result in inconsistent surface finishes and higher emissions due to exposure of resins and catalysts to air.

Overview of Closed Mold Process

Closed mold process involves injecting or placing resin into a sealed mold cavity, ensuring precise control over resin distribution and minimizing defects such as air entrapment and voids. This method enhances fiber wet-out, improves surface finish quality, and offers higher repeatability compared to open mold techniques. Common closed mold processes include resin transfer molding (RTM), compression molding, and vacuum infusion, widely used in high-performance composite manufacturing.

Key Differences Between Open and Closed Mold Processes

Open mold processes involve shaping composites in an exposed mold surface where excess resin can escape, resulting in higher emissions but easier mold access for large parts. Closed mold processes encapsulate the reinforcement between two matched mold halves, offering better control over resin flow, lower emissions, and improved surface finish on both sides. Key differences include environmental impact, resin containment, surface quality, and suitability for high-volume production.

Advantages of Open Mold Process

Open mold processes offer significant advantages including lower initial tooling costs and greater design flexibility, making them ideal for low to medium production volumes. They provide easier access for manual intervention, allowing for faster prototypes and custom parts with intricate shapes. Enhanced ventilation in open molds improves curing control and reduces the risk of trapped air, resulting in higher-quality composite parts.

Advantages of Closed Mold Process

The closed mold process offers superior control over resin distribution, resulting in improved part consistency and reduced material waste. This method also enhances worker safety by minimizing emissions and exposure to volatile organic compounds (VOCs). Higher production rates and better surface finishes are achieved due to the enclosed environment, making it ideal for high-volume composite manufacturing.

Limitations and Challenges of Each Process

Open mold processes face limitations such as lower surface finish quality, increased risk of environmental contamination, and higher labor intensity due to manual layup, which can lead to inconsistent part thickness and defects. Closed mold processes encounter challenges including higher initial tooling costs, complexity in designing effective molds for resin flow and venting, and potential trapping of air causing voids that affect structural integrity. Both methods struggle with controlling fiber orientation uniformly, impacting mechanical performance and repeatability in composite part manufacturing.

Material Compatibility in Open vs Closed Mold Techniques

Open mold processes typically utilize thermoset resins such as polyester, vinyl ester, and epoxy, which are compatible with reinforcements like fiberglass and carbon fiber, offering flexibility in material selection. Closed mold techniques, including resin transfer molding (RTM) and vacuum infusion, require resins with specific viscosity and cure characteristics to ensure proper flow and consolidation within the mold cavity, often favoring epoxy and advanced thermosetting systems. Material compatibility in closed molds enhances mechanical properties and surface finish quality, while open molds provide ease of repair and adaptability for varied composite structures.

Typical Applications for Open and Closed Mold Processes

Open mold processes are commonly utilized in manufacturing large composite structures such as boat hulls, automotive body panels, and wind turbine blades due to their cost-effectiveness and flexibility. Closed mold processes, including resin transfer molding (RTM) and compression molding, are preferred for high-volume production of automotive components, aerospace parts, and industrial equipment where precision, surface finish, and fiber alignment are critical. Both methods serve diverse industries, with open molding excelling in large, less complex parts and closed molding suited for high-precision, repeatable composite components.

Selecting the Right Process for Composite Production

Selecting the right process for composite production requires evaluating factors such as production volume, part complexity, and cost constraints. Open mold processes, like hand lay-up, suit low-volume, large, or complex parts but often result in higher labor costs and variability. Closed mold processes, including resin transfer molding and compression molding, enable higher consistency, faster cycle times, and better environmental control, making them ideal for high-volume and precision composite manufacturing.

Open Mold Process vs Closed Mold Process Infographic

materialdif.com

materialdif.com