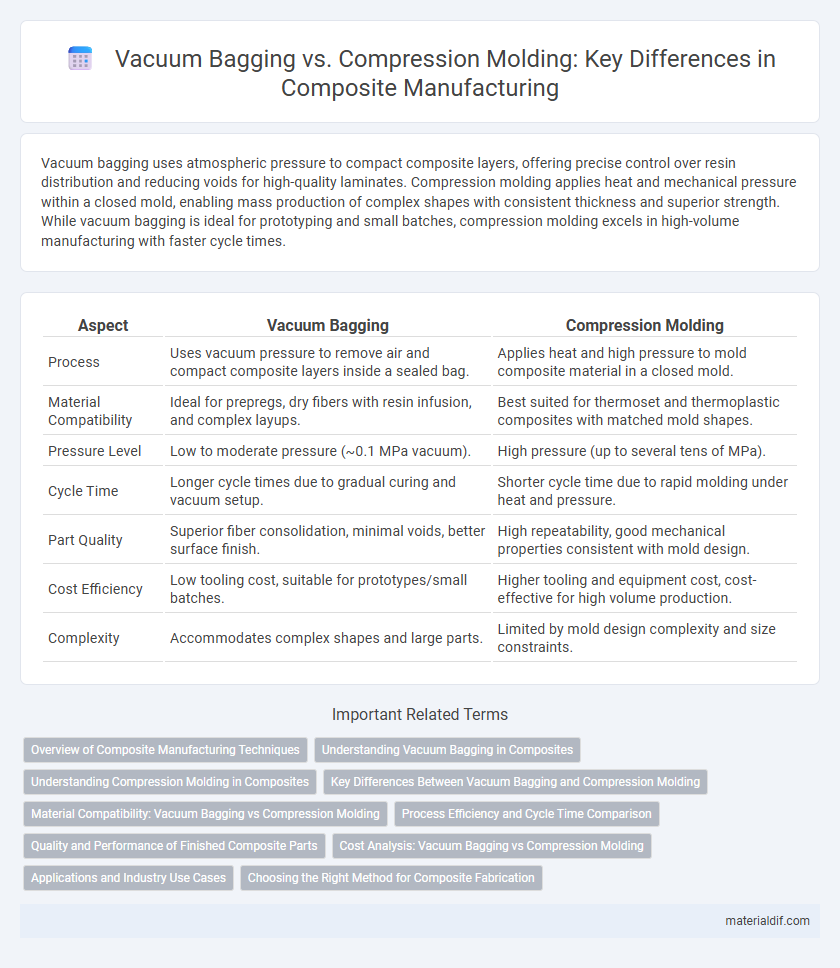

Vacuum bagging uses atmospheric pressure to compact composite layers, offering precise control over resin distribution and reducing voids for high-quality laminates. Compression molding applies heat and mechanical pressure within a closed mold, enabling mass production of complex shapes with consistent thickness and superior strength. While vacuum bagging is ideal for prototyping and small batches, compression molding excels in high-volume manufacturing with faster cycle times.

Table of Comparison

| Aspect | Vacuum Bagging | Compression Molding |

|---|---|---|

| Process | Uses vacuum pressure to remove air and compact composite layers inside a sealed bag. | Applies heat and high pressure to mold composite material in a closed mold. |

| Material Compatibility | Ideal for prepregs, dry fibers with resin infusion, and complex layups. | Best suited for thermoset and thermoplastic composites with matched mold shapes. |

| Pressure Level | Low to moderate pressure (~0.1 MPa vacuum). | High pressure (up to several tens of MPa). |

| Cycle Time | Longer cycle times due to gradual curing and vacuum setup. | Shorter cycle time due to rapid molding under heat and pressure. |

| Part Quality | Superior fiber consolidation, minimal voids, better surface finish. | High repeatability, good mechanical properties consistent with mold design. |

| Cost Efficiency | Low tooling cost, suitable for prototypes/small batches. | Higher tooling and equipment cost, cost-effective for high volume production. |

| Complexity | Accommodates complex shapes and large parts. | Limited by mold design complexity and size constraints. |

Overview of Composite Manufacturing Techniques

Vacuum bagging and compression molding are prominent composite manufacturing techniques used to enhance material properties and structural integrity. Vacuum bagging employs atmospheric pressure to consolidate resin-impregnated fibers, producing high-strength, lightweight components with excellent fiber-to-resin ratios. Compression molding utilizes heat and pressure within a mold cavity to shape and cure thermoset or thermoplastic composites rapidly, ideal for high-volume production with consistent dimensional accuracy.

Understanding Vacuum Bagging in Composites

Vacuum bagging in composites enhances resin distribution and fiber consolidation by applying uniform atmospheric pressure over the laminate, resulting in improved void reduction and increased mechanical properties. This technique uses a sealed bag and vacuum pump to remove air and excess resin, ensuring a lightweight and high-strength composite part. Compared to compression molding, vacuum bagging offers precise control over laminate thickness and resin content, making it ideal for aerospace and automotive composite applications.

Understanding Compression Molding in Composites

Compression molding in composites involves placing a pre-measured amount of resin and reinforcing fibers into a heated mold cavity, where pressure is applied to shape and cure the material. This process enables high production rates and consistent part quality, making it ideal for complex geometries and high-volume manufacturing. The controlled heat and pressure ensure enhanced fiber-resin adhesion, resulting in strong, lightweight composite components with excellent dimensional stability.

Key Differences Between Vacuum Bagging and Compression Molding

Vacuum bagging uses atmospheric pressure to compact composite layers within a sealed bag, creating uniform pressure ideal for complex shapes and reducing voids. Compression molding applies heat and high pressure through a mold to shape and cure composites rapidly, offering superior surface finish and high production rates. Key differences include vacuum bagging's lower pressure and longer cure times versus compression molding's higher pressure, faster cycle times, and suitability for mass production.

Material Compatibility: Vacuum Bagging vs Compression Molding

Vacuum bagging accommodates a wider range of thermoset and thermoplastic composite materials, including carbon fiber, fiberglass, and epoxy resins, due to its low-pressure process that preserves delicate fiber architectures. Compression molding requires materials with higher flow characteristics, such as prepregs and sheet molding compounds, optimized for heat and pressure to achieve dense, void-free parts. Material compatibility in vacuum bagging favors complex, large parts with variable thickness, whereas compression molding excels in high-volume production of uniform, geometrically consistent components.

Process Efficiency and Cycle Time Comparison

Vacuum bagging offers greater process efficiency for low-volume, complex composite parts due to its ability to uniformly distribute pressure and reduce void content, resulting in higher quality laminates. Compression molding excels in shorter cycle times for high-volume production, as it uses preheated molds and automated presses to rapidly cure thermoset resins under heat and pressure. Comparing both, vacuum bagging suits prototypes and small runs with longer cycles, while compression molding delivers fast throughput and consistent quality in large-scale manufacturing.

Quality and Performance of Finished Composite Parts

Vacuum bagging delivers superior surface finish and reduced void content by evenly distributing resin under controlled pressure, enhancing composite part quality. Compression molding offers consistent dimensional accuracy and high fiber volume fraction, leading to improved mechanical performance and structural integrity. Choosing between these methods depends on balancing the need for optimal surface aesthetics with the requirement for robust mechanical properties in composite manufacturing.

Cost Analysis: Vacuum Bagging vs Compression Molding

Vacuum bagging offers lower initial investment costs compared to compression molding, as it requires less expensive tooling and equipment. Compression molding, while demanding higher upfront expenses for molds and presses, benefits from faster cycle times and higher production volumes, leading to lower per-part costs in large manufacturing runs. For small to medium batch sizes, vacuum bagging remains a cost-effective option, whereas compression molding becomes more economical with scale due to its efficiency in mass production.

Applications and Industry Use Cases

Vacuum bagging is widely used in aerospace and marine industries for producing high-strength, lightweight composites with complex geometries, such as aircraft components and boat hulls, where precision and reduced void content are critical. Compression molding is favored in automotive and mass production sectors for manufacturing high-volume, durable composite parts like body panels and structural components, offering faster cycle times and consistent quality. Both methods support advanced materials like carbon fiber and fiberglass but are chosen based on application demands, production scale, and mechanical property requirements.

Choosing the Right Method for Composite Fabrication

Vacuum bagging offers precise control over fiber-to-resin ratio and is ideal for producing high-strength, lightweight composite parts with minimal void content. Compression molding excels in high-volume production, ensuring consistent part thickness and rapid cycle times, making it cost-effective for large-scale manufacturing. Selecting the right method depends on factors like production volume, part complexity, and mechanical property requirements.

Vacuum Bagging vs Compression Molding Infographic

materialdif.com

materialdif.com