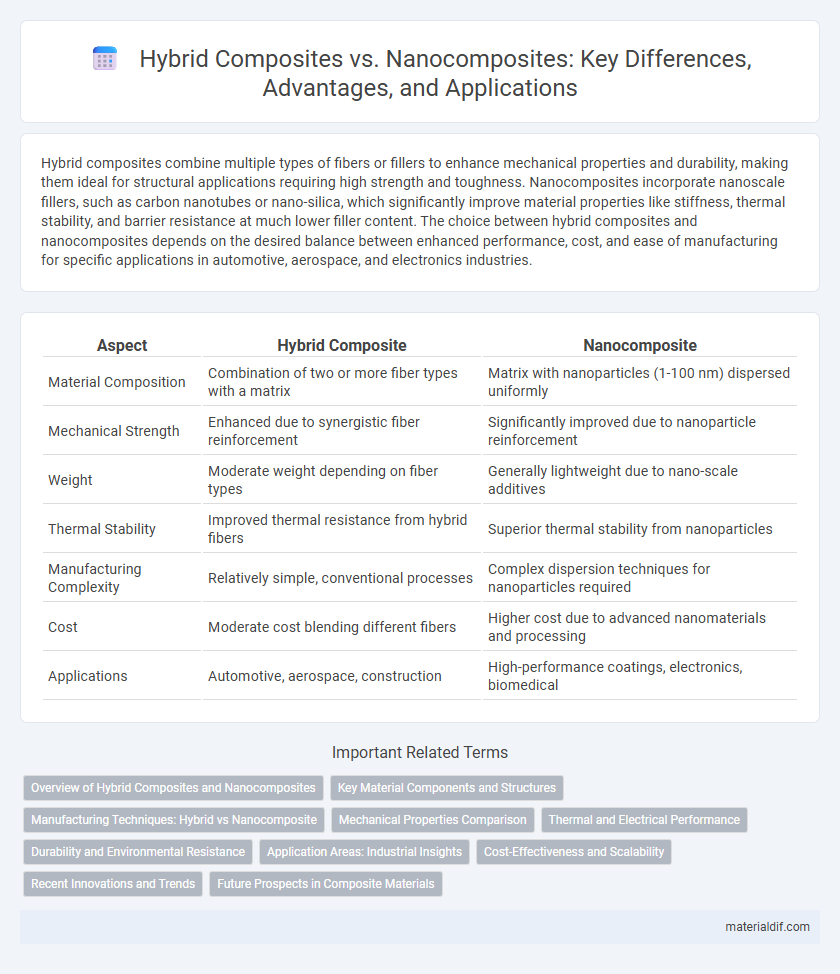

Hybrid composites combine multiple types of fibers or fillers to enhance mechanical properties and durability, making them ideal for structural applications requiring high strength and toughness. Nanocomposites incorporate nanoscale fillers, such as carbon nanotubes or nano-silica, which significantly improve material properties like stiffness, thermal stability, and barrier resistance at much lower filler content. The choice between hybrid composites and nanocomposites depends on the desired balance between enhanced performance, cost, and ease of manufacturing for specific applications in automotive, aerospace, and electronics industries.

Table of Comparison

| Aspect | Hybrid Composite | Nanocomposite |

|---|---|---|

| Material Composition | Combination of two or more fiber types with a matrix | Matrix with nanoparticles (1-100 nm) dispersed uniformly |

| Mechanical Strength | Enhanced due to synergistic fiber reinforcement | Significantly improved due to nanoparticle reinforcement |

| Weight | Moderate weight depending on fiber types | Generally lightweight due to nano-scale additives |

| Thermal Stability | Improved thermal resistance from hybrid fibers | Superior thermal stability from nanoparticles |

| Manufacturing Complexity | Relatively simple, conventional processes | Complex dispersion techniques for nanoparticles required |

| Cost | Moderate cost blending different fibers | Higher cost due to advanced nanomaterials and processing |

| Applications | Automotive, aerospace, construction | High-performance coatings, electronics, biomedical |

Overview of Hybrid Composites and Nanocomposites

Hybrid composites combine two or more distinct reinforcing materials such as fibers and particles to optimize mechanical, thermal, and chemical properties, achieving enhanced performance compared to conventional composites. Nanocomposites incorporate nanoscale fillers like carbon nanotubes, graphene, or nanoclays to significantly improve strength, stiffness, thermal stability, and electrical conductivity at low filler contents. Both hybrid composites and nanocomposites represent advanced material systems designed to overcome limitations of single-phase composites by leveraging synergistic effects between different reinforcement types.

Key Material Components and Structures

Hybrid composites integrate multiple fiber types such as glass, carbon, and Kevlar within a polymer matrix, optimizing mechanical strength, stiffness, and impact resistance through layered or intertwined fiber architectures. Nanocomposites incorporate nanoscale fillers like carbon nanotubes, graphene, or nanoclays dispersed within the matrix, enhancing material properties by increasing surface area and interfacial bonding at the atomic or molecular level. The key structural difference lies in hybrid composites' macroscale fiber reinforcements versus nanocomposites' nanoscale filler distribution, resulting in distinct performance enhancements tailored to specific applications.

Manufacturing Techniques: Hybrid vs Nanocomposite

Manufacturing techniques for hybrid composites often involve layering multiple fiber types with thermoset or thermoplastic matrices using processes such as hand lay-up, compression molding, or resin transfer molding, optimizing mechanical performance and cost-effectiveness. Nanocomposite fabrication typically requires advanced methods like in situ polymerization, sol-gel processing, or melt blending to uniformly disperse nanoparticles such as carbon nanotubes or nanosilica within polymer matrices, enhancing properties at the nanoscale. Control over nanoparticle distribution and interfacial bonding is critical in nanocomposites, while hybrid composites rely more on strategic fiber arrangement and matrix selection for tailored mechanical and thermal characteristics.

Mechanical Properties Comparison

Hybrid composites combine multiple types of reinforcement materials, such as glass and carbon fibers, enhancing tensile strength and impact resistance compared to single-fiber composites. Nanocomposites incorporate nanoscale fillers like carbon nanotubes or graphene, significantly improving mechanical properties such as stiffness, hardness, and fracture toughness at lower filler loadings. While hybrid composites excel in balancing strength and toughness over larger scales, nanocomposites offer superior mechanical enhancements at the nanoscale, leading to improved durability and performance in advanced engineering applications.

Thermal and Electrical Performance

Hybrid composites combine two or more different types of fillers to enhance thermal conductivity and electrical performance, achieving balanced properties suitable for advanced electronic applications. Nanocomposites, enriched with nanoscale fillers like carbon nanotubes or graphene, exhibit superior electrical conductivity and thermal management due to their high surface area and improved interfacial bonding. Thermal conductivity in hybrid composites typically ranges from 1 to 8 W/mK, whereas nanocomposites can exceed 10 W/mK, making nanocomposites more effective for high-performance thermal and electrical applications.

Durability and Environmental Resistance

Hybrid composites exhibit enhanced durability by combining fibers such as glass and carbon, offering improved impact resistance and fatigue life compared to conventional composites. Nanocomposites, infused with nanoparticles like carbon nanotubes or nanoclays, provide superior environmental resistance through increased barrier properties against moisture, UV radiation, and chemical degradation. Both materials advance composite technology, but nanocomposites typically deliver better long-term performance in harsh environmental conditions due to their nanoscale reinforcement.

Application Areas: Industrial Insights

Hybrid composites combine multiple fiber types like glass and carbon, enhancing mechanical strength and impact resistance for aerospace and automotive applications. Nanocomposites integrate nanoparticles such as carbon nanotubes or graphene, improving electrical conductivity and thermal stability, crucial for electronics and energy storage industries. Industrial applications leverage hybrid composites for structural components, while nanocomposites excel in sensors, coatings, and lightweight conductive materials.

Cost-Effectiveness and Scalability

Hybrid composites offer superior cost-effectiveness compared to nanocomposites due to the use of conventional fibers combined with nanoparticles, reducing raw material expenses and processing complexity. Scalability of hybrid composites is enhanced by established manufacturing techniques like resin transfer molding and filament winding, enabling large-scale production with consistent quality. Nanocomposites, while providing exceptional mechanical and thermal properties, face higher costs and scalability challenges because of specialized nanoparticle synthesis and dispersion requirements.

Recent Innovations and Trends

Recent innovations in hybrid composites focus on combining different fiber types, such as carbon and glass, to enhance mechanical properties and reduce weight in aerospace and automotive applications. Nanocomposites incorporate nanoscale fillers like carbon nanotubes or graphene, improving electrical conductivity, thermal stability, and strength at lower filler contents. Emerging trends emphasize eco-friendly bio-based matrices and multifunctional hybrid-nanocomposite systems for enhanced durability and smart material applications in advanced engineering.

Future Prospects in Composite Materials

Hybrid composites integrate multiple fiber types to enhance mechanical performance and cost-efficiency, while nanocomposites leverage nanoscale fillers to achieve superior strength, thermal stability, and multifunctionality. Future prospects in composite materials emphasize the development of hybrid-nanocomposite hybrids, combining macro- and nanoscale reinforcements for unprecedented property customization. Advancements in fabrication techniques and computational modeling are expected to accelerate innovations, enabling lightweight, high-performance composites for aerospace, automotive, and renewable energy sectors.

Hybrid composite vs Nanocomposite Infographic

materialdif.com

materialdif.com