Unidirectional fiber composites offer superior strength and stiffness along a single axis, making them ideal for applications requiring targeted load-bearing capabilities. Woven fabric composites provide multidirectional strength and improved impact resistance due to their interlaced fiber structure, enhancing overall durability. Selecting between unidirectional fibers and woven fabrics depends on the specific mechanical performance and flexibility required for the composite application.

Table of Comparison

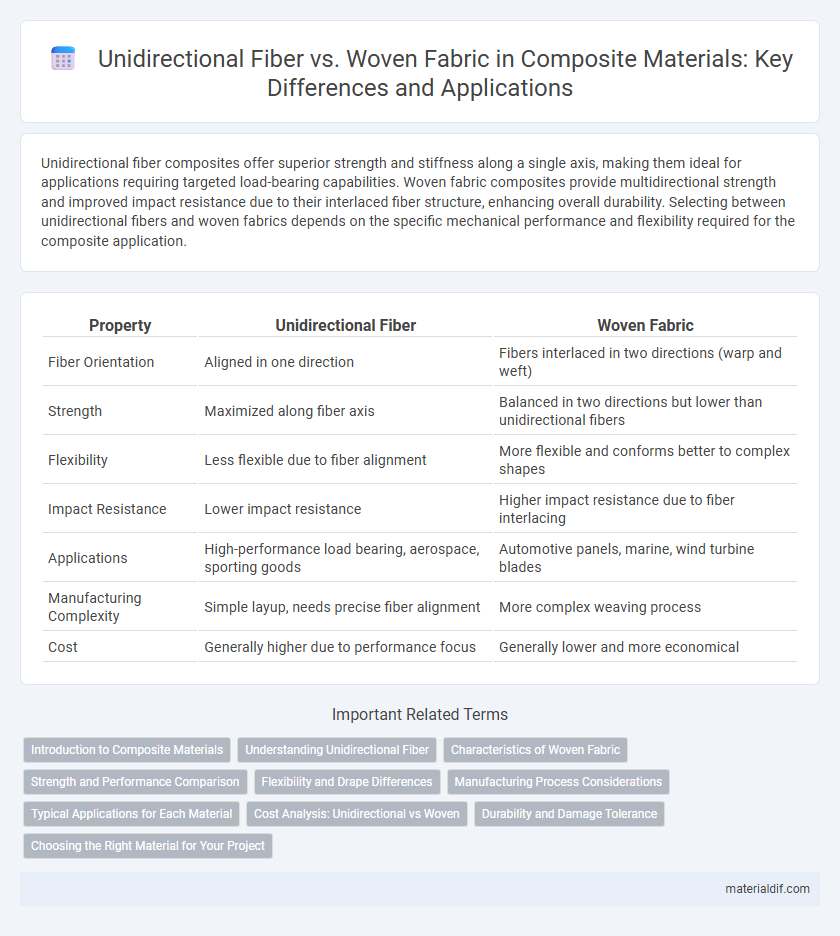

| Property | Unidirectional Fiber | Woven Fabric |

|---|---|---|

| Fiber Orientation | Aligned in one direction | Fibers interlaced in two directions (warp and weft) |

| Strength | Maximized along fiber axis | Balanced in two directions but lower than unidirectional fibers |

| Flexibility | Less flexible due to fiber alignment | More flexible and conforms better to complex shapes |

| Impact Resistance | Lower impact resistance | Higher impact resistance due to fiber interlacing |

| Applications | High-performance load bearing, aerospace, sporting goods | Automotive panels, marine, wind turbine blades |

| Manufacturing Complexity | Simple layup, needs precise fiber alignment | More complex weaving process |

| Cost | Generally higher due to performance focus | Generally lower and more economical |

Introduction to Composite Materials

Unidirectional fiber composites offer high strength and stiffness along a single axis, making them ideal for applications requiring directional load-bearing capabilities. Woven fabric composites provide balanced mechanical properties in multiple directions due to their interlaced fiber architecture, enhancing impact resistance and damage tolerance. Both fiber orientations play crucial roles in tailoring composite materials for aerospace, automotive, and sporting goods industries.

Understanding Unidirectional Fiber

Unidirectional fiber composites consist of fibers aligned in a single direction, providing maximum strength and stiffness along that axis, which is ideal for load-bearing applications. These fibers exhibit high tensile strength and stiffness, making them suitable for aerospace and automotive components where directional load resistance is critical. Unlike woven fabrics, unidirectional fibers lack the crimp and flexibility, resulting in superior mechanical performance along the fiber direction but reduced resistance to multi-directional stresses.

Characteristics of Woven Fabric

Woven fabric in composites features interlaced fibers arranged at right angles, providing enhanced dimensional stability and resistance to deformation. This structure allows for superior impact resistance and balanced mechanical properties in multiple directions compared to unidirectional fibers. The crimp in woven fabric fibers may reduce tensile strength but improves damage tolerance and handling during manufacturing.

Strength and Performance Comparison

Unidirectional fiber composites exhibit superior tensile strength and stiffness along the fiber direction, making them ideal for applications requiring high load-bearing capacity in a single axis. Woven fabric composites provide enhanced multi-directional strength and improved damage tolerance due to their interlaced fiber architecture, offering balanced performance under complex loading conditions. The choice between unidirectional and woven fabric composites depends on specific strength requirements and loading environments, with unidirectional fibers excelling in directional performance and woven fabrics delivering overall durability and impact resistance.

Flexibility and Drape Differences

Unidirectional fiber composites exhibit superior strength along the fiber axis but offer limited flexibility and poor drape due to the rigid alignment of fibers. In contrast, woven fabric composites provide enhanced flexibility and excellent draping capabilities because the interlaced fibers distribute stress more evenly and conform better to complex shapes. This difference makes unidirectional fibers ideal for high-strength, linear applications, while woven fabrics excel in molded or curved structures requiring greater adaptability.

Manufacturing Process Considerations

Unidirectional fiber composites feature fibers aligned in a single direction, allowing precise control during layup and ensuring high tensile strength along the fiber axis, making manufacturing simpler and faster with less fabric handling. Woven fabric composites involve interlaced fibers in multiple directions, which enhances dimensional stability and impact resistance but increases complexity due to fabric crimp and more intricate alignment during molding. Manufacturing processes for unidirectional fibers often include automated tape placement and filament winding, while woven fabrics typically require careful cutting and nesting to optimize material usage and minimize defects.

Typical Applications for Each Material

Unidirectional fiber composites are predominantly used in aerospace components, high-performance sporting goods, and wind turbine blades due to their exceptional strength and stiffness along a single axis. Woven fabric composites find typical applications in automotive body panels, marine structures, and protective gear where multi-directional strength and impact resistance are crucial. Selecting between unidirectional fiber and woven fabric depends heavily on the load distribution and performance requirements of the specific application.

Cost Analysis: Unidirectional vs Woven

Unidirectional fiber composites typically incur higher raw material costs due to the precise fiber alignment required, but offer superior strength-to-weight ratios that can reduce overall system expenses. Woven fabrics present lower upfront material costs and easier handling during manufacturing, resulting in reduced labor and processing time. Cost analysis must balance the higher price of unidirectional fibers against the efficiency gains and performance benefits they deliver compared to the more economical yet heavier woven fabric options.

Durability and Damage Tolerance

Unidirectional fiber composites offer superior tensile strength along the fiber direction but exhibit lower damage tolerance and durability when subjected to multidirectional stresses or impact. Woven fabric composites provide enhanced damage tolerance and durability due to their interlaced fiber architecture, which distributes loads more evenly and resists crack propagation. The choice between unidirectional fiber and woven fabric depends on application requirements prioritizing either directional strength or overall durability.

Choosing the Right Material for Your Project

Unidirectional fiber composites offer superior tensile strength and stiffness along a single axis, making them ideal for applications requiring high load-bearing capacity in one direction. Woven fabric composites provide multidirectional strength and better impact resistance due to their interlaced fiber structure, suitable for components subjected to complex stress patterns. Selecting the right material depends on the mechanical performance needed, with unidirectional fibers favored for directional strength and woven fabrics chosen for enhanced durability and flexibility.

Unidirectional Fiber vs Woven Fabric Infographic

materialdif.com

materialdif.com