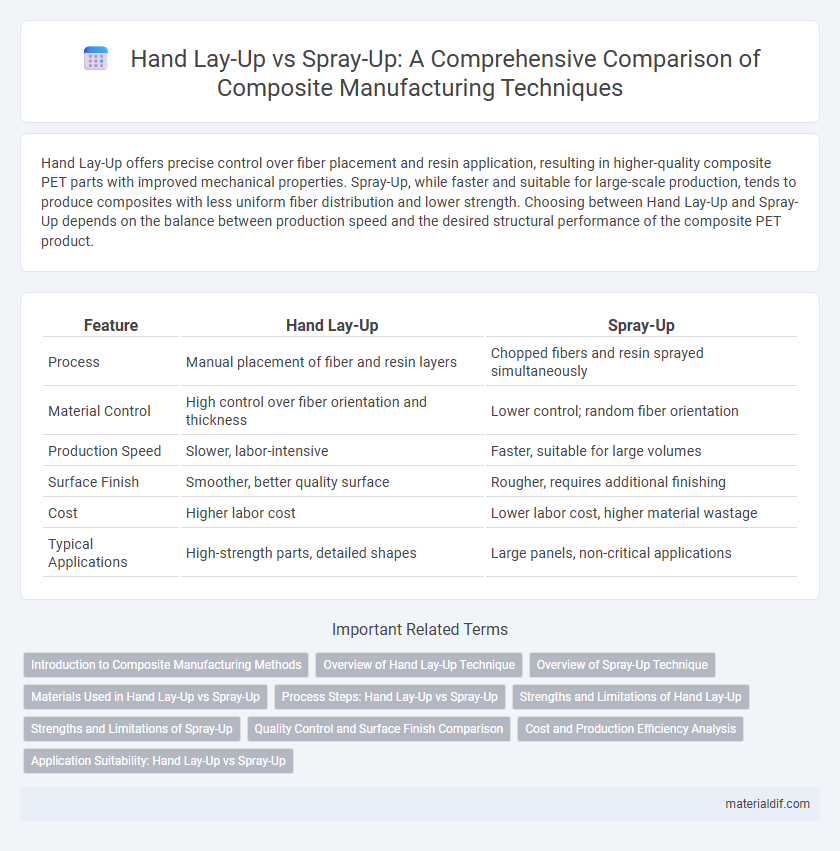

Hand Lay-Up offers precise control over fiber placement and resin application, resulting in higher-quality composite PET parts with improved mechanical properties. Spray-Up, while faster and suitable for large-scale production, tends to produce composites with less uniform fiber distribution and lower strength. Choosing between Hand Lay-Up and Spray-Up depends on the balance between production speed and the desired structural performance of the composite PET product.

Table of Comparison

| Feature | Hand Lay-Up | Spray-Up |

|---|---|---|

| Process | Manual placement of fiber and resin layers | Chopped fibers and resin sprayed simultaneously |

| Material Control | High control over fiber orientation and thickness | Lower control; random fiber orientation |

| Production Speed | Slower, labor-intensive | Faster, suitable for large volumes |

| Surface Finish | Smoother, better quality surface | Rougher, requires additional finishing |

| Cost | Higher labor cost | Lower labor cost, higher material wastage |

| Typical Applications | High-strength parts, detailed shapes | Large panels, non-critical applications |

Introduction to Composite Manufacturing Methods

Hand Lay-Up and Spray-Up are fundamental composite manufacturing methods used to create fiber-reinforced polymer structures. Hand Lay-Up involves manually placing reinforcement fibers and applying resin layer by layer, offering precision and control over fiber orientation and thickness. Spray-Up uses a spray gun to simultaneously apply chopped fibers and resin, enabling faster production but with less fiber alignment and lower structural performance compared to Hand Lay-Up.

Overview of Hand Lay-Up Technique

Hand lay-up is a fundamental composite manufacturing technique involving the manual placement of reinforcement fibers onto a mold, followed by the application of resin to saturate the fibers. This process allows precise control over fiber orientation and resin distribution, leading to tailored mechanical properties in the finished composite part. Commonly used for low-volume production and large, complex shapes, hand lay-up offers cost-effective tooling and versatility compared to automated methods like spray-up.

Overview of Spray-Up Technique

Spray-up is a composite fabrication process where chopped glass fibers and resin are simultaneously sprayed onto a mold using a pneumatic spray gun, allowing for rapid application and forming of complex shapes. This technique offers greater production speed and flexibility for large or intricate parts compared to hand lay-up, but may result in lower fiber content and mechanical strength. Spray-up is commonly used in marine, automotive, and architectural industries where moderate strength and cost efficiency are prioritized.

Materials Used in Hand Lay-Up vs Spray-Up

Hand lay-up primarily uses woven reinforcing fibers such as fiberglass or carbon fiber mats combined with polyester, vinyl ester, or epoxy resins, allowing precise fiber orientation and thickness control. Spray-up employs chopped fiberglass strands mixed with resin, applied via spray guns, which accelerates production but may result in lower fiber volume fraction and weaker mechanical properties. Material selection in hand lay-up favors high-performance applications requiring strength and durability, while spray-up suits large, less structurally demanding components.

Process Steps: Hand Lay-Up vs Spray-Up

Hand lay-up involves manually placing reinforcement fibers into a mold and applying resin with brushes or rollers, allowing precise control over fiber orientation and resin distribution. Spray-up utilizes a chopper gun to cut and spray fibers and resin simultaneously onto the mold surface, enabling faster application but with less control over fiber alignment. Both processes require careful mold preparation, curing, and post-curing steps to ensure optimal composite strength and finish quality.

Strengths and Limitations of Hand Lay-Up

Hand lay-up offers superior control over fiber orientation and resin distribution, resulting in higher structural integrity and improved mechanical strength for composite parts. Its main limitation lies in labor intensity and slower production rates compared to spray-up, making it less suitable for large-scale manufacturing. This method is ideal for prototype development and low-volume, high-quality applications where precision is critical.

Strengths and Limitations of Spray-Up

Spray-up offers rapid application and cost efficiency for large-scale composite parts, making it ideal for bulk production with moderate structural requirements. Its limitations include lower fiber control and reduced structural strength compared to hand lay-up, resulting in less consistent fiber distribution and potential voids. Spray-up is best suited for non-structural components where speed outweighs the need for high mechanical performance.

Quality Control and Surface Finish Comparison

Hand lay-up offers superior quality control due to precise manual placement of fibers and resin, resulting in fewer voids and better laminate consistency compared to spray-up. Spray-up typically produces a rougher surface finish with higher potential for surface defects, while hand lay-up achieves a smoother, more uniform finish ideal for cosmetic and structural applications. Effective quality control in hand lay-up involves meticulous inspection and curing processes, whereas spray-up relies more on post-process treatments to improve surface quality.

Cost and Production Efficiency Analysis

Hand lay-up involves manually placing reinforcement fibers and resin, resulting in lower initial equipment costs but slower production rates. Spray-up uses choppers and spray guns to accelerate resin and fiber deposition, increasing production efficiency but requiring higher capital investment. Cost analysis shows hand lay-up is more economical for small batches, while spray-up excels in high-volume manufacturing due to faster cycle times and reduced labor expenses.

Application Suitability: Hand Lay-Up vs Spray-Up

Hand lay-up offers superior precision and control, making it ideal for complex, low-volume composite parts requiring high strength and detailed finishes. Spray-up is better suited for large-scale, less intricate applications where speed and coverage are prioritized over fine detail and mechanical properties. Choosing between hand lay-up and spray-up depends on factors such as part size, complexity, production volume, and desired surface quality.

Hand Lay-Up vs Spray-Up Infographic

materialdif.com

materialdif.com