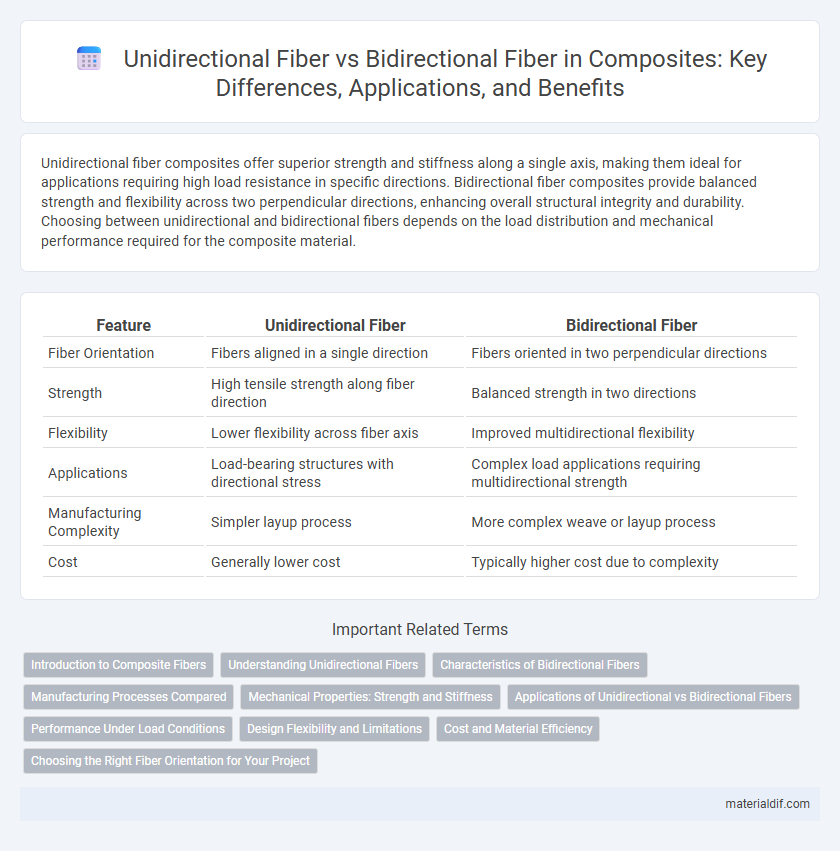

Unidirectional fiber composites offer superior strength and stiffness along a single axis, making them ideal for applications requiring high load resistance in specific directions. Bidirectional fiber composites provide balanced strength and flexibility across two perpendicular directions, enhancing overall structural integrity and durability. Choosing between unidirectional and bidirectional fibers depends on the load distribution and mechanical performance required for the composite material.

Table of Comparison

| Feature | Unidirectional Fiber | Bidirectional Fiber |

|---|---|---|

| Fiber Orientation | Fibers aligned in a single direction | Fibers oriented in two perpendicular directions |

| Strength | High tensile strength along fiber direction | Balanced strength in two directions |

| Flexibility | Lower flexibility across fiber axis | Improved multidirectional flexibility |

| Applications | Load-bearing structures with directional stress | Complex load applications requiring multidirectional strength |

| Manufacturing Complexity | Simpler layup process | More complex weave or layup process |

| Cost | Generally lower cost | Typically higher cost due to complexity |

Introduction to Composite Fibers

Unidirectional fiber composites consist of fibers aligned in a single direction, providing exceptional strength and stiffness along that axis, making them ideal for load-bearing applications. Bidirectional fiber composites feature fibers woven or arranged in two perpendicular directions, offering balanced mechanical properties and enhanced resistance to shear forces. Both fiber orientations are essential in composite manufacturing, allowing engineers to optimize material performance based on specific structural demands.

Understanding Unidirectional Fibers

Unidirectional fibers in composites are aligned parallel in a single direction, providing exceptional strength and stiffness along that axis, which is ideal for load-bearing applications requiring high tensile performance. These fibers optimize mechanical properties by maximizing strength-to-weight ratio and enhancing fatigue resistance in the specific fiber direction. Understanding their behavior is crucial for designing lightweight, high-strength composite structures used in aerospace, automotive, and sporting goods industries.

Characteristics of Bidirectional Fibers

Bidirectional fibers exhibit enhanced mechanical performance by offering balanced strength and stiffness along both warp and weft directions, improving load distribution in composite materials. Their interlaced structure provides superior damage tolerance and resistance to delamination compared to unidirectional fibers. This multidirectional reinforcement makes bidirectional fibers ideal for applications requiring complex load-bearing capabilities and dimensional stability.

Manufacturing Processes Compared

Unidirectional fiber composites are manufactured by aligning fibers in a single direction, which simplifies the lay-up process and ensures maximum strength along the fiber axis. Bidirectional fiber composites involve weaving or layering fibers in two perpendicular directions, resulting in enhanced multidirectional strength but requiring more complex fabrication steps such as weaving or cross-ply lamination. Manufacturing bidirectional composites often demands precise control over fiber orientation and resin impregnation to achieve optimal mechanical properties.

Mechanical Properties: Strength and Stiffness

Unidirectional fibers exhibit superior tensile strength and stiffness along the fiber direction due to continuous fiber alignment, making them ideal for load-bearing applications requiring high strength-to-weight ratios. Bidirectional fibers enhance in-plane mechanical properties by providing balanced strength and stiffness in two perpendicular directions, improving resistance to shear and impact loads. The choice between unidirectional and bidirectional fibers depends on the mechanical demands and load orientation in composite design.

Applications of Unidirectional vs Bidirectional Fibers

Unidirectional fibers are extensively used in aerospace and automotive industries where high strength and stiffness are required along a single axis, such as in wing spars and drive shafts. Bidirectional fibers provide enhanced strength and stability in multiple directions, making them ideal for applications like pressure vessels, boat hulls, and sports equipment where multi-axial loads occur. The choice between unidirectional and bidirectional fibers directly impacts the mechanical performance and durability of composite structures in specific engineering applications.

Performance Under Load Conditions

Unidirectional fiber composites exhibit superior tensile strength along the fiber axis, making them highly efficient under uniaxial loading conditions. Bidirectional fiber composites provide balanced mechanical properties with enhanced shear strength and better resistance to multi-axial stresses, improving overall structural integrity. Performance under load conditions depends on the alignment of fibers with the principal load direction, where unidirectional fibers excel in stiffness and strength along one axis, while bidirectional fibers offer more isotropic load distribution.

Design Flexibility and Limitations

Unidirectional fiber composites offer high strength and stiffness primarily along one axis, making them ideal for load-bearing components requiring directional reinforcement but limiting design flexibility due to anisotropic properties. Bidirectional fiber composites enhance multidirectional strength and stiffness, allowing greater design adaptability by distributing loads more evenly across two axes, yet they may result in lower peak mechanical performance compared to unidirectional fibers. Designers must balance the trade-offs between optimized directional strength in unidirectional fibers and the versatile load distribution in bidirectional composites to meet specific structural and functional requirements.

Cost and Material Efficiency

Unidirectional fiber composites typically offer greater material efficiency and lower costs due to their simplified manufacturing process and focused fiber alignment, which maximizes strength along a single axis. Bidirectional fiber composites incorporate fibers woven in two directions, enhancing multidirectional strength but increasing material usage and production complexity, thus elevating costs. Selecting between unidirectional and bidirectional fibers depends on the application requirements for load-bearing directions and budget constraints.

Choosing the Right Fiber Orientation for Your Project

Selecting the appropriate fiber orientation in composite materials significantly impacts mechanical performance and durability. Unidirectional fibers provide superior strength and stiffness along a single axis, ideal for applications requiring high tensile load capacity in one direction. Bidirectional fibers offer balanced strength and improved dimensional stability across two directions, making them suitable for components subjected to multi-axial stresses and complex load conditions.

Unidirectional Fiber vs Bidirectional Fiber Infographic

materialdif.com

materialdif.com