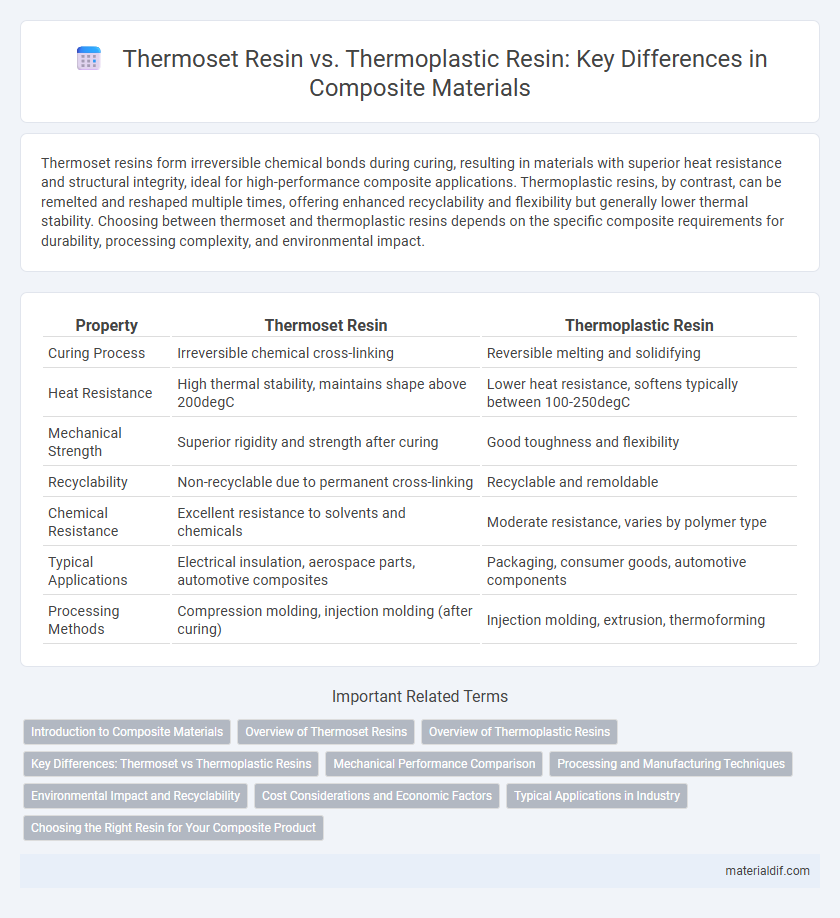

Thermoset resins form irreversible chemical bonds during curing, resulting in materials with superior heat resistance and structural integrity, ideal for high-performance composite applications. Thermoplastic resins, by contrast, can be remelted and reshaped multiple times, offering enhanced recyclability and flexibility but generally lower thermal stability. Choosing between thermoset and thermoplastic resins depends on the specific composite requirements for durability, processing complexity, and environmental impact.

Table of Comparison

| Property | Thermoset Resin | Thermoplastic Resin |

|---|---|---|

| Curing Process | Irreversible chemical cross-linking | Reversible melting and solidifying |

| Heat Resistance | High thermal stability, maintains shape above 200degC | Lower heat resistance, softens typically between 100-250degC |

| Mechanical Strength | Superior rigidity and strength after curing | Good toughness and flexibility |

| Recyclability | Non-recyclable due to permanent cross-linking | Recyclable and remoldable |

| Chemical Resistance | Excellent resistance to solvents and chemicals | Moderate resistance, varies by polymer type |

| Typical Applications | Electrical insulation, aerospace parts, automotive composites | Packaging, consumer goods, automotive components |

| Processing Methods | Compression molding, injection molding (after curing) | Injection molding, extrusion, thermoforming |

Introduction to Composite Materials

Thermoset resins, such as epoxy and polyester, chemically cure into a rigid, infusible network, providing excellent mechanical strength and thermal stability ideal for high-performance composite materials. Thermoplastic resins like polypropylene and nylon soften upon heating, allowing for better impact resistance and recyclability in composite manufacturing. Understanding the distinct curing and physical properties of thermoset and thermoplastic resins is crucial for optimizing composite material performance in applications ranging from aerospace to automotive industries.

Overview of Thermoset Resins

Thermoset resins, including epoxy, polyester, and phenolic types, form irreversible chemical bonds during curing, resulting in a rigid, heat-resistant structure ideal for high-performance composite materials. These resins exhibit excellent dimensional stability, superior mechanical strength, and outstanding resistance to heat, chemicals, and electrical insulation compared to thermoplastics. Common applications span aerospace, automotive, and electrical industries where durability and thermal stability are critical.

Overview of Thermoplastic Resins

Thermoplastic resins are polymers that become pliable or moldable above a specific temperature and solidify upon cooling, enabling repeated reshaping without significant chemical change. Common examples include polyethylene, polypropylene, and polycarbonate, which offer excellent impact resistance, chemical stability, and recyclability. These properties make thermoplastic resins ideal for composite applications requiring durability, lightweight structure, and efficient manufacturing processes.

Key Differences: Thermoset vs Thermoplastic Resins

Thermoset resins form irreversible chemical bonds during curing, resulting in a rigid and heat-resistant composite, whereas thermoplastic resins soften upon heating and can be remolded multiple times. Key differences include thermosets' superior thermal stability and mechanical strength compared to the flexibility and recyclability offered by thermoplastics. In composite manufacturing, thermoset resins are ideal for high-performance, durable applications, while thermoplastic resins enable faster processing and repairability.

Mechanical Performance Comparison

Thermoset resins exhibit superior mechanical strength and thermal stability compared to thermoplastic resins, making them ideal for high-load structural applications. Their rigid cross-linked polymer networks provide enhanced resistance to deformation and creep under stress, while thermoplastics offer greater flexibility and impact resistance due to their linear molecular chains. This fundamental difference results in thermosets outperforming thermoplastics in stiffness, hardness, and dimensional stability within composite materials.

Processing and Manufacturing Techniques

Thermoset resins undergo irreversible curing through heat or chemical reactions, resulting in a rigid and heat-resistant composite, ideal for high-strength structural applications. Thermoplastic resins melt upon heating and can be repeatedly reshaped and solidified, enabling processes like injection molding, extrusion, and thermoforming for faster and more flexible manufacturing. Manufacturing techniques for thermoset composites typically involve hand lay-up, compression molding, and resin transfer molding, while thermoplastic composites benefit from automated processes such as automated fiber placement and hot pressing.

Environmental Impact and Recyclability

Thermoset resins, commonly used in composites, have a cross-linked molecular structure that makes them difficult to recycle and results in longer degradation times in the environment. Thermoplastic resins offer better recyclability due to their ability to be melted and reformed multiple times, reducing landfill waste and environmental pollution. The environmental impact of thermoplastics is generally lower, as their recyclability supports circular economy initiatives and decreases reliance on virgin raw materials.

Cost Considerations and Economic Factors

Thermoset resins generally incur higher initial tooling and curing costs due to irreversible cross-linking, leading to longer production cycles and increased labor expenses compared to thermoplastic resins. Thermoplastics offer cost advantages in high-volume manufacturing with faster cycle times and recyclability, reducing material waste and lowering overall production expenses. Economic factors such as lifecycle cost analysis favor thermoplastics for applications requiring cost-effective mass production, while thermosets justify expense through superior thermal stability and mechanical properties in specialty composite parts.

Typical Applications in Industry

Thermoset resin is widely used in aerospace, automotive, and electrical industries due to its excellent heat resistance, mechanical strength, and dimensional stability in components like circuit boards, insulation, and structural parts. Thermoplastic resin finds typical applications in packaging, consumer goods, and automotive interiors, offering benefits such as recyclability, impact resistance, and ease of molding in products like containers, toys, and dashboards. The choice between thermoset and thermoplastic resins depends on performance requirements, with thermosets favored for high-temperature and high-strength applications and thermoplastics preferred for flexible, lightweight, and cost-effective manufacturing.

Choosing the Right Resin for Your Composite Product

Thermoset resins, such as epoxy and phenolic, offer superior heat resistance and dimensional stability, making them ideal for high-performance composite products requiring structural integrity under extreme conditions. Thermoplastic resins like polypropylene and polycarbonate provide excellent impact resistance and recyclability, suitable for applications needing toughness and reprocessing capabilities. Selecting the right resin depends on factors including mechanical properties, thermal stability, manufacturing process, and end-use requirements of the composite product.

Thermoset Resin vs Thermoplastic Resin Infographic

materialdif.com

materialdif.com