Hybrid composites combine two or more different materials to enhance mechanical properties, offering improved strength, durability, and resistance compared to monolithic composites composed of a single material. The combination of fibers and matrix materials in hybrid composites allows for tailored performance characteristics, optimizing weight and cost efficiency for specific applications. Monolithic composites, while simpler to manufacture, often lack the versatility and enhanced performance found in hybrid composites, limiting their use in advanced engineering fields.

Table of Comparison

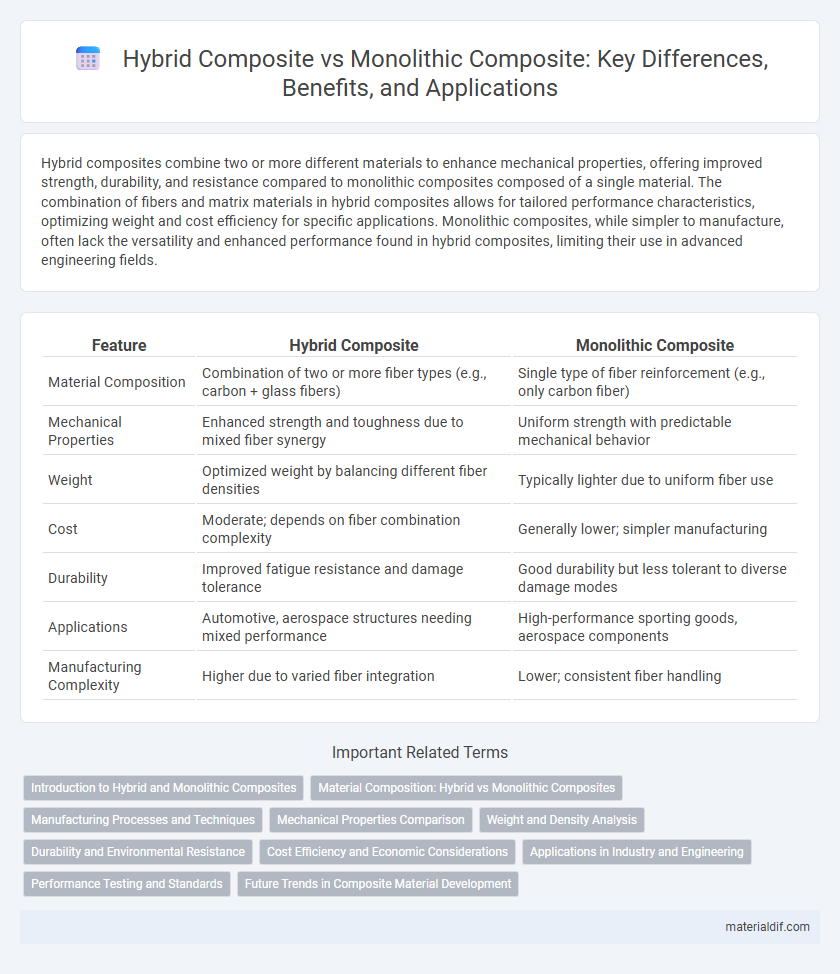

| Feature | Hybrid Composite | Monolithic Composite |

|---|---|---|

| Material Composition | Combination of two or more fiber types (e.g., carbon + glass fibers) | Single type of fiber reinforcement (e.g., only carbon fiber) |

| Mechanical Properties | Enhanced strength and toughness due to mixed fiber synergy | Uniform strength with predictable mechanical behavior |

| Weight | Optimized weight by balancing different fiber densities | Typically lighter due to uniform fiber use |

| Cost | Moderate; depends on fiber combination complexity | Generally lower; simpler manufacturing |

| Durability | Improved fatigue resistance and damage tolerance | Good durability but less tolerant to diverse damage modes |

| Applications | Automotive, aerospace structures needing mixed performance | High-performance sporting goods, aerospace components |

| Manufacturing Complexity | Higher due to varied fiber integration | Lower; consistent fiber handling |

Introduction to Hybrid and Monolithic Composites

Hybrid composites combine two or more different fiber types or matrix materials to optimize mechanical properties such as strength, stiffness, and impact resistance, offering tailored performance for diverse engineering applications. Monolithic composites consist of a single fiber and matrix combination, providing uniform characteristics but often lacking the multifunctional capabilities seen in hybrids. Understanding the distinctions in material composition and structural behavior is crucial for selecting the appropriate composite type in aerospace, automotive, and construction industries.

Material Composition: Hybrid vs Monolithic Composites

Hybrid composites combine two or more distinct fiber types or matrix materials within a single structure, optimizing mechanical properties such as strength, stiffness, and impact resistance by leveraging the advantages of each constituent. Monolithic composites consist of a single type of fiber and matrix material, offering uniformity in composition but potentially limited performance adaptability compared to hybrid systems. The diverse material composition in hybrid composites enables tailored properties for specific applications, improving durability and functionality beyond the capabilities of monolithic composites.

Manufacturing Processes and Techniques

Hybrid composites combine two or more different types of fibers or matrices, utilizing diverse manufacturing processes such as hand lay-up, resin transfer molding (RTM), and filament winding to optimize material properties and reduce weight. Monolithic composites typically rely on a single fiber-matrix combination and are produced using standardized techniques like autoclave curing and compression molding, emphasizing uniformity and strength. Advanced manufacturing techniques for hybrid composites enable tailored mechanical performance by precisely controlling fiber orientation, layering sequence, and resin infusion patterns, surpassing the flexibility of monolithic composite fabrication.

Mechanical Properties Comparison

Hybrid composites exhibit superior mechanical properties compared to monolithic composites due to the synergistic combination of different fiber types, resulting in enhanced tensile strength, impact resistance, and fatigue performance. Monolithic composites, while often lighter and simpler to manufacture, typically possess lower fracture toughness and reduced damage tolerance compared to hybrid variants. The tailored fiber orientation and matrix compatibility in hybrid composites enable improved stiffness and durability under complex loading conditions.

Weight and Density Analysis

Hybrid composites exhibit lower weight and optimized density compared to monolithic composites due to their combination of different fiber and matrix materials, achieving enhanced strength-to-weight ratios. The density of hybrid composites can be precisely tailored by adjusting fiber volume fractions, resulting in lighter structures without compromising mechanical performance. Monolithic composites typically have higher density and weight, limiting their application in weight-sensitive industries such as aerospace and automotive sectors.

Durability and Environmental Resistance

Hybrid composites exhibit superior durability compared to monolithic composites due to their combined fiber matrices, which enhance impact resistance and fatigue life. Environmental resistance in hybrid composites is significantly higher, as the integration of diverse materials improves resistance to moisture, UV radiation, and chemical degradation. Monolithic composites, while simpler in structure, often lack the multi-faceted protective qualities that hybrid composites leverage for prolonged performance in harsh conditions.

Cost Efficiency and Economic Considerations

Hybrid composites offer cost efficiency by combining materials to optimize performance while reducing overall material expenses compared to monolithic composites, which often require costly high-purity fibers or matrices. Economic considerations favor hybrid composites in large-scale applications due to their balanced mechanical properties and lower production costs, enabling manufacturers to meet budget constraints without compromising strength or durability. Lifecycle cost analysis shows hybrid composites typically result in better return on investment by minimizing maintenance and replacement frequency relative to monolithic counterparts.

Applications in Industry and Engineering

Hybrid composites combine two or more different fiber types, such as carbon and glass fibers, enhancing mechanical properties like strength, stiffness, and impact resistance compared to monolithic composites made from a single fiber type. In aerospace, automotive, and marine industries, hybrid composites are favored for structural components requiring tailored performance and damage tolerance, while monolithic composites are prevalent in applications demanding uniform properties and lower cost. Industrial engineering utilizes hybrid composites in load-bearing parts and protective gear, leveraging their optimized balance of weight, durability, and fatigue resistance.

Performance Testing and Standards

Hybrid composites demonstrate superior performance testing outcomes compared to monolithic composites, showing enhanced strength-to-weight ratio and impact resistance due to their multi-material reinforcement. Standards such as ASTM D3039 for tensile testing and ASTM D7136 for impact testing are critical in evaluating these materials, ensuring consistency and reliability in performance metrics. Hybrid composites meet or exceed these standardized criteria more effectively by combining the advantageous properties of different fibers and matrices.

Future Trends in Composite Material Development

Hybrid composites combine two or more distinct materials, offering tailored properties like enhanced strength-to-weight ratio and improved damage tolerance compared to monolithic composites, which consist of a single material phase. Future trends in composite material development emphasize multifunctional hybrid composites integrated with smart sensors for real-time structural health monitoring and adaptive response capabilities. Advances in nanotechnology and additive manufacturing are expected to accelerate the design of next-generation hybrid composites with superior mechanical performance and sustainability.

Hybrid composite vs Monolithic composite Infographic

materialdif.com

materialdif.com