Autoclave curing applies heat and pressure simultaneously, resulting in superior composite material consolidation, reduced void content, and enhanced mechanical properties compared to oven curing. Oven curing relies solely on heat, often leading to longer cycle times and potentially higher void content within the composite structure. Choosing autoclave curing improves composite performance in critical aerospace and automotive applications where strength and durability are paramount.

Table of Comparison

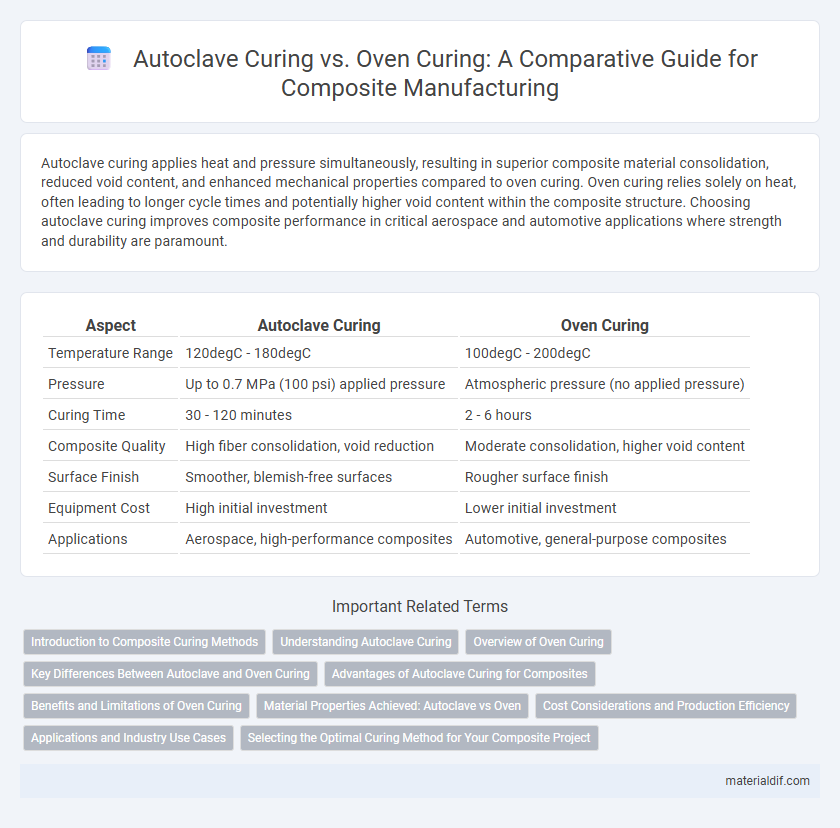

| Aspect | Autoclave Curing | Oven Curing |

|---|---|---|

| Temperature Range | 120degC - 180degC | 100degC - 200degC |

| Pressure | Up to 0.7 MPa (100 psi) applied pressure | Atmospheric pressure (no applied pressure) |

| Curing Time | 30 - 120 minutes | 2 - 6 hours |

| Composite Quality | High fiber consolidation, void reduction | Moderate consolidation, higher void content |

| Surface Finish | Smoother, blemish-free surfaces | Rougher surface finish |

| Equipment Cost | High initial investment | Lower initial investment |

| Applications | Aerospace, high-performance composites | Automotive, general-purpose composites |

Introduction to Composite Curing Methods

Composite curing methods primarily include autoclave curing and oven curing, each offering distinct advantages in manufacturing quality and performance. Autoclave curing utilizes high pressure and temperature to enhance fiber consolidation and resin flow, resulting in superior mechanical properties and reduced void content. Oven curing operates under atmospheric pressure, providing a cost-effective solution with adequate curing performance for less critical composite applications.

Understanding Autoclave Curing

Autoclave curing utilizes high pressure and heat to enhance composite material consolidation, improving fiber-matrix bonding and reducing void content. This process operates typically at temperatures between 120degC and 180degC with pressures up to 7 bar, resulting in superior mechanical properties and dimensional stability compared to oven curing. Autoclave curing is essential for aerospace-grade composites where performance and reliability are critical.

Overview of Oven Curing

Oven curing is a thermal process used to harden composite materials by applying controlled heat in a sealed chamber, typically ranging from 120degC to 180degC. This method promotes chemical cross-linking in thermosetting resins, enhancing mechanical properties and structural integrity without the pressure constraints found in autoclave curing. Oven curing is favored for its cost-effectiveness and scalability in manufacturing composite parts with consistent quality, especially for larger components where autoclave capacity is limited.

Key Differences Between Autoclave and Oven Curing

Autoclave curing applies elevated pressure and temperature simultaneously, enhancing composite part consolidation and reducing void content, while oven curing relies solely on heat, often resulting in lower fiber volume fractions and potential porosity. The autoclave process typically achieves superior mechanical properties and surface finish due to uniform pressure distribution, whereas oven curing offers cost efficiency and scalability for less critical applications. Cycle times in autoclaves are generally longer due to pressurization phases, contrasting with faster, simpler oven curing but at the expense of composite quality.

Advantages of Autoclave Curing for Composites

Autoclave curing offers superior pressure and temperature control, resulting in enhanced composite material properties such as higher fiber volume fraction and reduced void content. This method ensures uniform consolidation and improved mechanical strength compared to oven curing, which relies primarily on heat alone. Autoclave curing's precision significantly improves the performance and reliability of aerospace-grade and high-performance composite components.

Benefits and Limitations of Oven Curing

Oven curing offers cost-effective and scalable heat treatment for composite materials, allowing precise temperature control and uniform curing suitable for large or complex parts. Its limitations include longer cycle times compared to autoclave curing and lower pressure capability, which can result in reduced fiber consolidation and potential void formation. Oven curing is best suited for composites where moderate mechanical properties suffice and high-pressure consolidation is not critical.

Material Properties Achieved: Autoclave vs Oven

Autoclave curing produces composites with superior fiber consolidation, higher void reduction, and improved resin distribution compared to oven curing, resulting in enhanced mechanical properties like increased tensile strength and stiffness. Oven curing typically leads to slightly higher void content and less uniform resin flow, which may cause reduced interlaminar shear strength and overall durability. The controlled pressure and temperature environment in autoclave curing optimizes polymer cross-linking, achieving superior material density and fatigue resistance in composite structures.

Cost Considerations and Production Efficiency

Autoclave curing typically incurs higher operational costs due to increased energy consumption and maintenance requirements compared to oven curing, which is more cost-effective for large-volume production. Production efficiency in autoclave curing benefits from superior pressure and temperature control, resulting in higher-quality composites with reduced defects and less rework. Oven curing offers faster cycle times and easier scalability, making it ideal for mass production despite slightly lower mechanical performance in composites.

Applications and Industry Use Cases

Autoclave curing offers superior pressure and temperature control, making it ideal for aerospace and high-performance automotive composite manufacturing where enhanced mechanical properties and defect reduction are critical. Oven curing is preferred in industries like wind energy and marine, where cost-effective, large-scale production of composite parts with moderate performance requirements suffices. Both methods serve distinct industry needs, balancing precision and scalability in composite part fabrication.

Selecting the Optimal Curing Method for Your Composite Project

Selecting the optimal curing method for your composite project depends on factors such as material type, part size, and desired mechanical properties. Autoclave curing ensures superior fiber consolidation and void elimination through high pressure and temperature, ideal for aerospace-grade composites. Oven curing offers cost-effective processing for larger, less critical parts but may result in lower material strength and dimensional accuracy compared to autoclave methods.

Autoclave Curing vs Oven Curing Infographic

materialdif.com

materialdif.com