RTM (Resin Transfer Molding) offers precise control over resin flow and faster cycle times, making it ideal for high-volume production of complex composite parts. Vacuum Infusion provides superior fiber wet-out and reduces void content by using vacuum pressure to draw resin into the laminate, enhancing mechanical properties and part consistency. Comparing both, RTM requires expensive molds and equipment, while Vacuum Infusion is more cost-effective for low to medium volumes with simpler tooling needs.

Table of Comparison

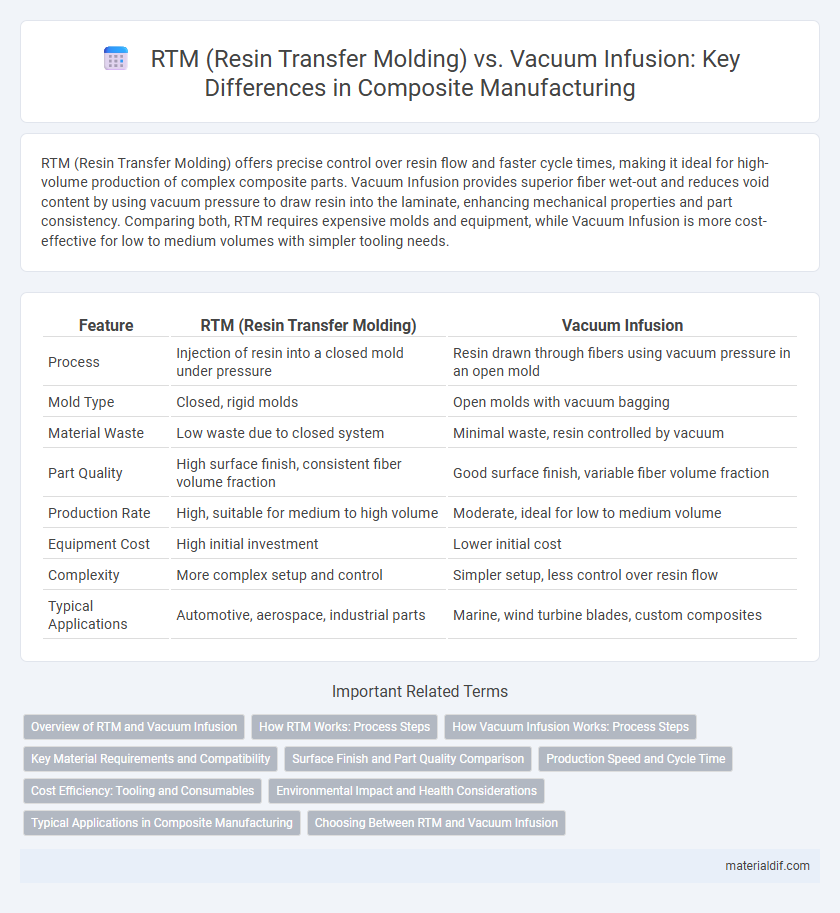

| Feature | RTM (Resin Transfer Molding) | Vacuum Infusion |

|---|---|---|

| Process | Injection of resin into a closed mold under pressure | Resin drawn through fibers using vacuum pressure in an open mold |

| Mold Type | Closed, rigid molds | Open molds with vacuum bagging |

| Material Waste | Low waste due to closed system | Minimal waste, resin controlled by vacuum |

| Part Quality | High surface finish, consistent fiber volume fraction | Good surface finish, variable fiber volume fraction |

| Production Rate | High, suitable for medium to high volume | Moderate, ideal for low to medium volume |

| Equipment Cost | High initial investment | Lower initial cost |

| Complexity | More complex setup and control | Simpler setup, less control over resin flow |

| Typical Applications | Automotive, aerospace, industrial parts | Marine, wind turbine blades, custom composites |

Overview of RTM and Vacuum Infusion

Resin Transfer Molding (RTM) is a closed-mold process where resin is injected under pressure into a reinforced fiber preform, enabling high-quality, repeatable composite parts with excellent surface finish and dimensional accuracy. Vacuum Infusion involves drawing resin into a dry fiber layup sealed under vacuum, offering cost-effective production and excellent fiber wet-out but with lower control over resin flow compared to RTM. Both methods cater to different requirements in composite manufacturing, with RTM suited for high-volume, complex shapes and Vacuum Infusion favored for large, simple structures and low tooling costs.

How RTM Works: Process Steps

Resin Transfer Molding (RTM) involves placing dry fiber reinforcements into a closed mold cavity, followed by injecting resin under pressure to thoroughly saturate the fibers and cure within precise cycle times. The controlled environment of RTM ensures uniform resin distribution and minimizes void content, enhancing composite part quality and mechanical performance. This process includes mold preparation, fiber placement, resin injection, curing, and demolding, making RTM well-suited for complex, high-volume composite manufacturing.

How Vacuum Infusion Works: Process Steps

Vacuum Infusion works by placing dry fiber reinforcements in a mold and sealing it with a vacuum bag before evacuating air to create a vacuum. Resin is introduced through inlet ports, allowing it to flow and saturate the fibers uniformly under vacuum pressure. This process ensures improved resin distribution, reduced void content, and enhanced composite part quality compared to Resin Transfer Molding (RTM).

Key Material Requirements and Compatibility

RTM requires low-viscosity resins compatible with closed molds to ensure complete fiber saturation and minimal void content, favoring high-performance epoxy or polyester resins. Vacuum Infusion demands materials with high permeability fabrics and resins capable of slow, controlled flow to fill complex geometries without dry spots, often utilizing vinyl ester or epoxy systems designed for atmospheric pressure infusion. Compatibility hinges on resin cure kinetics and fiber architecture matching process pressures and temperatures to optimize mechanical properties and surface finish.

Surface Finish and Part Quality Comparison

Resin Transfer Molding (RTM) typically produces superior surface finishes with smoother and more uniform resin distribution compared to Vacuum Infusion, due to the controlled injection of resin under pressure. Part quality in RTM benefits from reduced void content and enhanced fiber wet-out, resulting in higher mechanical properties and consistent dimensional accuracy. Conversely, Vacuum Infusion can lead to variability in surface finish and may require additional finishing processes to achieve the same level of quality found in RTM-manufactured components.

Production Speed and Cycle Time

RTM (Resin Transfer Molding) offers faster production speed compared to Vacuum Infusion due to its closed mold process that enables rapid resin injection and curing. Cycle times in RTM typically range from a few minutes to an hour, significantly shorter than Vacuum Infusion, which can take several hours due to slower resin flow and longer curing periods. This efficiency makes RTM more suitable for medium to high-volume composite production where reduced cycle time is critical.

Cost Efficiency: Tooling and Consumables

Resin Transfer Molding (RTM) typically incurs higher initial costs due to expensive tooling and molds, which are designed for high-volume production and dimensional precision. Vacuum Infusion offers lower tooling expenses with reusable consumables, making it more cost-effective for small to medium production runs. Consumable costs in RTM are generally less per part when amortized over volume, whereas Vacuum Infusion requires continuous purchase of vacuum bags and peel plies, affecting long-term cost efficiency.

Environmental Impact and Health Considerations

Resin Transfer Molding (RTM) generally produces less waste due to precise resin application and closed mold systems, reducing volatile organic compound (VOC) emissions compared to Vacuum Infusion, which may expose operators to higher VOC levels during open mold processes. Vacuum Infusion, while often using lower-viscosity resins, can result in prolonged exposure to styrene and other hazardous fumes if not properly ventilated, posing health risks such as respiratory irritation. Both methods benefit from using bio-based or low-VOC resins to minimize environmental impact and improve workplace safety, but RTM's controlled environment inherently reduces emissions and exposure.

Typical Applications in Composite Manufacturing

RTM (Resin Transfer Molding) is commonly used in high-volume production of complex composite parts such as automotive components, aerospace structural elements, and sports equipment due to its precise resin control and superior surface finish. Vacuum Infusion is preferred for large, high-strength marine structures, wind turbine blades, and custom aerospace components where low void content and high fiber volume fractions are critical. Both methods excel in producing durable, lightweight composites but differ in scalability and application complexity, making RTM ideal for intricate geometries and vacuum infusion suitable for large, flat or moderately contoured parts.

Choosing Between RTM and Vacuum Infusion

Choosing between RTM (Resin Transfer Molding) and Vacuum Infusion depends on production volume, complexity, and surface finish requirements. RTM offers superior precision and repeatability for high-volume, complex composite parts with excellent surface quality on both sides. Vacuum Infusion is more cost-effective for low to medium volumes, enabling large, lightweight laminates with good mechanical properties but less surface finish control.

RTM (Resin Transfer Molding) vs Vacuum Infusion Infographic

materialdif.com

materialdif.com