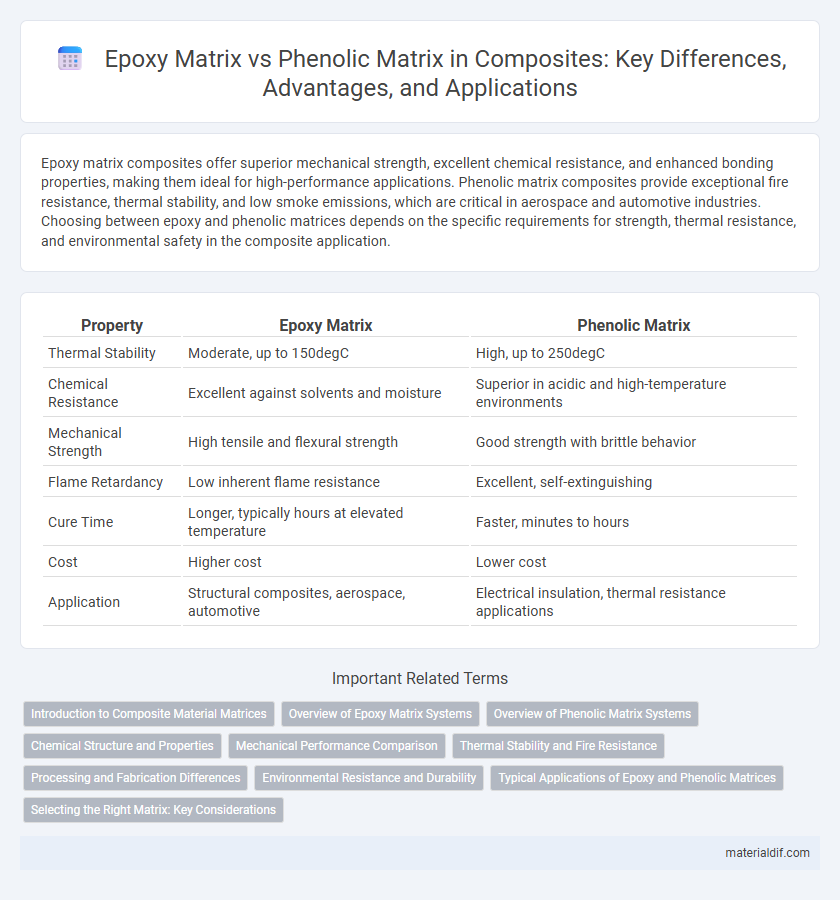

Epoxy matrix composites offer superior mechanical strength, excellent chemical resistance, and enhanced bonding properties, making them ideal for high-performance applications. Phenolic matrix composites provide exceptional fire resistance, thermal stability, and low smoke emissions, which are critical in aerospace and automotive industries. Choosing between epoxy and phenolic matrices depends on the specific requirements for strength, thermal resistance, and environmental safety in the composite application.

Table of Comparison

| Property | Epoxy Matrix | Phenolic Matrix |

|---|---|---|

| Thermal Stability | Moderate, up to 150degC | High, up to 250degC |

| Chemical Resistance | Excellent against solvents and moisture | Superior in acidic and high-temperature environments |

| Mechanical Strength | High tensile and flexural strength | Good strength with brittle behavior |

| Flame Retardancy | Low inherent flame resistance | Excellent, self-extinguishing |

| Cure Time | Longer, typically hours at elevated temperature | Faster, minutes to hours |

| Cost | Higher cost | Lower cost |

| Application | Structural composites, aerospace, automotive | Electrical insulation, thermal resistance applications |

Introduction to Composite Material Matrices

Epoxy matrix composites offer superior mechanical strength, chemical resistance, and adhesive properties, making them ideal for high-performance aerospace and automotive applications. Phenolic matrix composites provide exceptional thermal stability, flame resistance, and low smoke emission, which are critical in fire-retardant and electrical insulation uses. Understanding the distinct characteristics of epoxy and phenolic matrices enables optimized selection based on temperature tolerance, durability, and specific application requirements in composite material engineering.

Overview of Epoxy Matrix Systems

Epoxy matrix systems are widely used in composite materials due to their superior mechanical properties, excellent chemical resistance, and strong adhesion to fibers. These thermosetting resins provide high thermal stability and low shrinkage during curing, ensuring enhanced durability and dimensional stability in structural applications. Compared to phenolic matrix systems, epoxies offer better toughness and flexibility, making them ideal for aerospace, automotive, and high-performance industrial components.

Overview of Phenolic Matrix Systems

Phenolic matrix systems in composites are distinguished by their excellent thermal stability, fire resistance, and low smoke emission, making them ideal for aerospace and automotive applications. These thermosetting resins exhibit strong chemical resistance and superior dimensional stability under high temperatures compared to epoxy matrices. Phenolic composites typically provide enhanced flame retardancy and are preferred in environments where stringent fire safety standards are required.

Chemical Structure and Properties

Epoxy matrix composites consist of epoxide groups that form highly cross-linked, thermosetting polymers with excellent adhesion, chemical resistance, and mechanical strength. Phenolic matrix composites contain phenol-formaldehyde resins, characterized by a highly aromatic structure that imparts superior thermal stability, flame resistance, and low smoke emissions. Epoxy matrices generally offer better toughness and moisture resistance, while phenolic matrices excel in high-temperature environments and fire retardancy.

Mechanical Performance Comparison

Epoxy matrix composites exhibit higher tensile strength and superior impact resistance compared to phenolic matrix composites, making them suitable for demanding structural applications. Phenolic matrix composites demonstrate better thermal stability and fire resistance but generally have lower fracture toughness and elongation at break than epoxy systems. The choice between epoxy and phenolic matrices depends on balancing mechanical performance requirements with thermal and fire safety considerations in composite design.

Thermal Stability and Fire Resistance

Epoxy matrix composites exhibit high thermal stability with glass transition temperatures typically ranging from 120degC to 180degC, making them suitable for moderate heat applications. Phenolic matrix composites surpass epoxy in fire resistance due to their inherent char-forming ability and self-extinguishing properties, often maintaining structural integrity above 200degC and under direct flame exposure. The superior thermal decomposition temperature and low smoke emission of phenolic matrices make them ideal for aerospace and automotive components requiring stringent fire safety standards.

Processing and Fabrication Differences

Epoxy matrix composites offer superior processing versatility due to their longer curing times and lower curing temperatures, enabling complex shapes and large-scale fabrications with enhanced dimensional control. Phenolic matrix composites require higher curing temperatures and shorter cure cycles, which result in faster production but pose challenges in molding intricate geometries. The inherent brittleness and limited post-curing flexibility of phenolic matrices demand specialized handling and processing equipment compared to the more adaptable epoxy systems.

Environmental Resistance and Durability

Epoxy matrix composites exhibit superior environmental resistance and durability compared to phenolic matrix composites, with enhanced resistance to moisture, chemicals, and UV degradation. The cross-linked structure of epoxy resins provides excellent mechanical stability and prolonged lifespan under harsh environmental conditions, making them ideal for aerospace and automotive applications. Phenolic matrices offer good thermal stability and flame resistance but tend to absorb more moisture, leading to reduced durability in wet or chemically aggressive environments.

Typical Applications of Epoxy and Phenolic Matrices

Epoxy matrices are extensively utilized in aerospace components, sporting goods, and automotive parts due to their superior mechanical strength and excellent chemical resistance. Phenolic matrices find typical applications in high-temperature environments such as fire-resistant panels, circuit boards, and brake linings, benefiting from their exceptional thermal stability and flame retardant properties. Both matrices enhance composite performance but are selected based on specific application requirements like temperature resistance and mechanical demands.

Selecting the Right Matrix: Key Considerations

Selecting the right matrix for composites involves evaluating mechanical properties, chemical resistance, and thermal stability, with epoxy matrix offering superior adhesion and toughness, while phenolic matrix provides excellent fire resistance and low smoke emission. Cost-effectiveness and processing techniques also influence the decision, as epoxy matrices typically require controlled curing conditions compared to phenolic matrices that offer easier molding processes. Understanding the specific application requirements, such as load-bearing capacity or exposure to high temperatures, ensures optimal performance and durability in composite materials.

Epoxy Matrix vs Phenolic Matrix Infographic

materialdif.com

materialdif.com