RTM (Resin Transfer Molding) offers superior fiber wet-out and consistent resin distribution compared to hand lay-up, resulting in higher quality composite PET parts with enhanced mechanical properties. Hand lay-up is more labor-intensive and prone to variability, as manual resin application can cause voids and inconsistent thickness. RTM's closed mold process also improves environmental safety by minimizing VOC emissions during composite PET manufacturing.

Table of Comparison

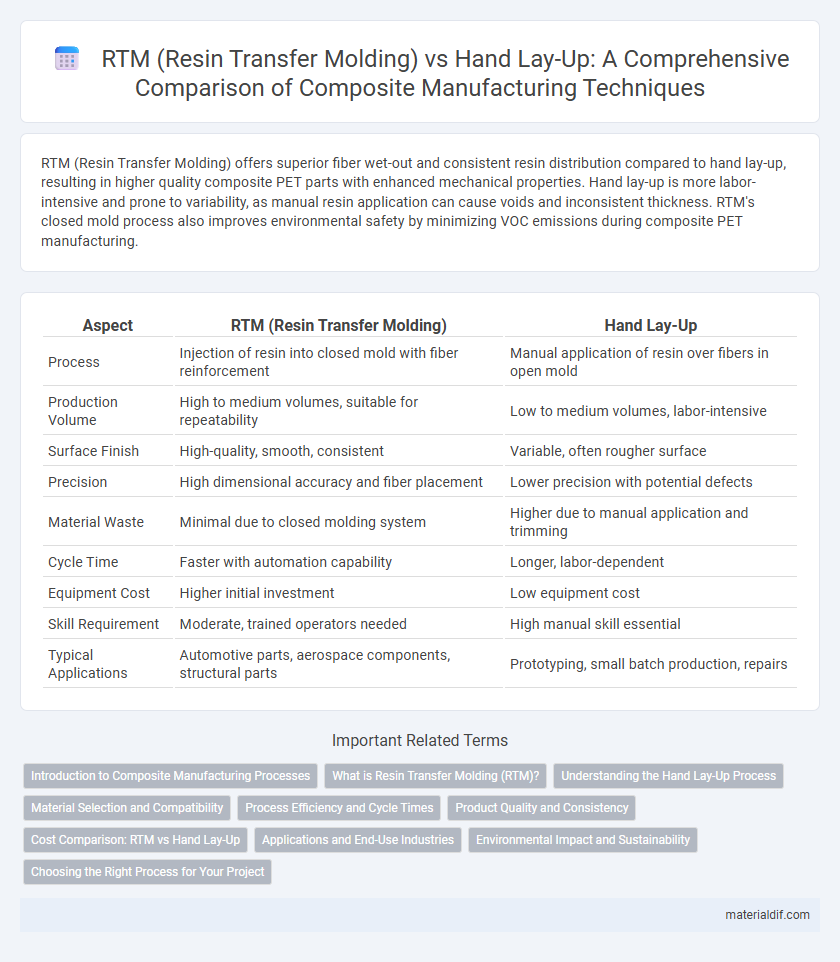

| Aspect | RTM (Resin Transfer Molding) | Hand Lay-Up |

|---|---|---|

| Process | Injection of resin into closed mold with fiber reinforcement | Manual application of resin over fibers in open mold |

| Production Volume | High to medium volumes, suitable for repeatability | Low to medium volumes, labor-intensive |

| Surface Finish | High-quality, smooth, consistent | Variable, often rougher surface |

| Precision | High dimensional accuracy and fiber placement | Lower precision with potential defects |

| Material Waste | Minimal due to closed molding system | Higher due to manual application and trimming |

| Cycle Time | Faster with automation capability | Longer, labor-dependent |

| Equipment Cost | Higher initial investment | Low equipment cost |

| Skill Requirement | Moderate, trained operators needed | High manual skill essential |

| Typical Applications | Automotive parts, aerospace components, structural parts | Prototyping, small batch production, repairs |

Introduction to Composite Manufacturing Processes

RTM (Resin Transfer Molding) offers precise control over resin flow and fiber impregnation, resulting in consistent, high-quality composite parts with reduced void content compared to Hand Lay-Up. Hand Lay-Up remains a cost-effective, straightforward process ideal for low-volume or large, simple shapes but often yields variable quality due to manual resin application and fiber placement. RTM's closed mold approach enhances dimensional accuracy and surface finish, making it preferable for complex geometries and high-performance composite manufacturing.

What is Resin Transfer Molding (RTM)?

Resin Transfer Molding (RTM) is a closed-mold composite manufacturing process where resin is injected under pressure into a mold containing a dry fiber preform. RTM offers precise control over resin distribution, resulting in high-quality, consistent parts with superior mechanical properties and surface finish compared to traditional hand lay-up methods. This technique significantly reduces void content and enhances part repeatability, making it ideal for complex geometries and high-volume production runs.

Understanding the Hand Lay-Up Process

Hand lay-up is a manual composite fabrication technique where reinforcing fibers are placed in a mold before being saturated with resin, allowing precise control over fiber orientation and thickness. This process is favored for low-volume, large, and complex parts due to its flexibility and minimal tooling costs compared to Resin Transfer Molding (RTM). While RTM offers automation and uniform resin distribution through injection, hand lay-up remains advantageous for custom, small-batch production requiring detailed craftsmanship.

Material Selection and Compatibility

RTM (Resin Transfer Molding) offers precise control over material selection, enabling the use of low-viscosity resins that enhance fiber wet-out and reduce void content, resulting in superior composite quality. Hand Lay-Up relies on manual resin application, often limiting resin types to those with higher viscosity, which may lead to inconsistent fiber impregnation and potential compatibility issues. Material compatibility in RTM is optimized through closed-mold processing, minimizing exposure to contaminants and allowing the use of specialized reinforcements, whereas Hand Lay-Up's open-mold approach increases the risk of resin contamination and inconsistent bond strength.

Process Efficiency and Cycle Times

RTM (Resin Transfer Molding) offers superior process efficiency compared to Hand Lay-Up by automating resin infusion and reducing manual labor, resulting in consistent part quality. Cycle times for RTM are significantly shorter, often completing in minutes to hours versus the several hours or days required for Hand Lay-Up curing and finishing. This efficiency in RTM enhances high-volume production capabilities while minimizing material waste and rework.

Product Quality and Consistency

Resin Transfer Molding (RTM) offers superior product quality and consistency compared to Hand Lay-Up due to its controlled resin flow and precise mold clamping, resulting in uniform fiber wet-out and reduced void content. RTM enables high reproducibility with tight dimensional tolerances, minimizing defects associated with manual application in Hand Lay-Up processes. The automation potential in RTM further enhances batch-to-batch consistency, crucial for aerospace and automotive composite components.

Cost Comparison: RTM vs Hand Lay-Up

Resin Transfer Molding (RTM) generally incurs higher initial setup costs compared to Hand Lay-Up due to mold fabrication and machinery expenses, but it offers lower labor costs and higher production efficiency over time. Hand Lay-Up requires minimal equipment investment and is cost-effective for low-volume or prototype runs, though it involves intensive manual labor, leading to higher labor expenses in larger production scales. The choice between RTM and Hand Lay-Up depends on production volume, with RTM becoming more cost-efficient for medium to high volumes due to automation and repeatability advantages.

Applications and End-Use Industries

Resin Transfer Molding (RTM) excels in producing high-performance composite parts with complex geometries, making it ideal for aerospace, automotive, and renewable energy sectors requiring precision and structural integrity. Hand Lay-Up is favored in marine, construction, and low-volume manufacturing industries due to its cost-effectiveness and simplicity for producing large, less intricate components. Both methods cater to specific end-use demands, with RTM offering superior surface finish and mechanical properties, while Hand Lay-Up provides flexibility and lower tooling costs for customized or prototype composite parts.

Environmental Impact and Sustainability

RTM (Resin Transfer Molding) significantly reduces volatile organic compound (VOC) emissions compared to Hand Lay-Up due to its closed mold process, leading to lower environmental pollution. Energy consumption in RTM is generally more efficient, resulting in a smaller carbon footprint and less material waste, contributing to sustainable composite manufacturing. Hand Lay-Up's open molding releases higher emissions and generates more scrap, posing greater challenges for eco-friendly production.

Choosing the Right Process for Your Project

RTM (Resin Transfer Molding) offers precise control over fiber placement and resin infusion, resulting in high-quality, consistent composite parts ideal for complex shapes and medium to high production volumes. Hand Lay-Up provides flexibility and lower initial costs, making it suitable for low-volume, custom, or large parts where labor-intensive craftsmanship is acceptable. Evaluating factors such as part complexity, production scale, surface finish requirements, and budget constraints is crucial when choosing between RTM and Hand Lay-Up processes for composite manufacturing.

RTM (Resin Transfer Molding) vs Hand Lay-Up Infographic

materialdif.com

materialdif.com