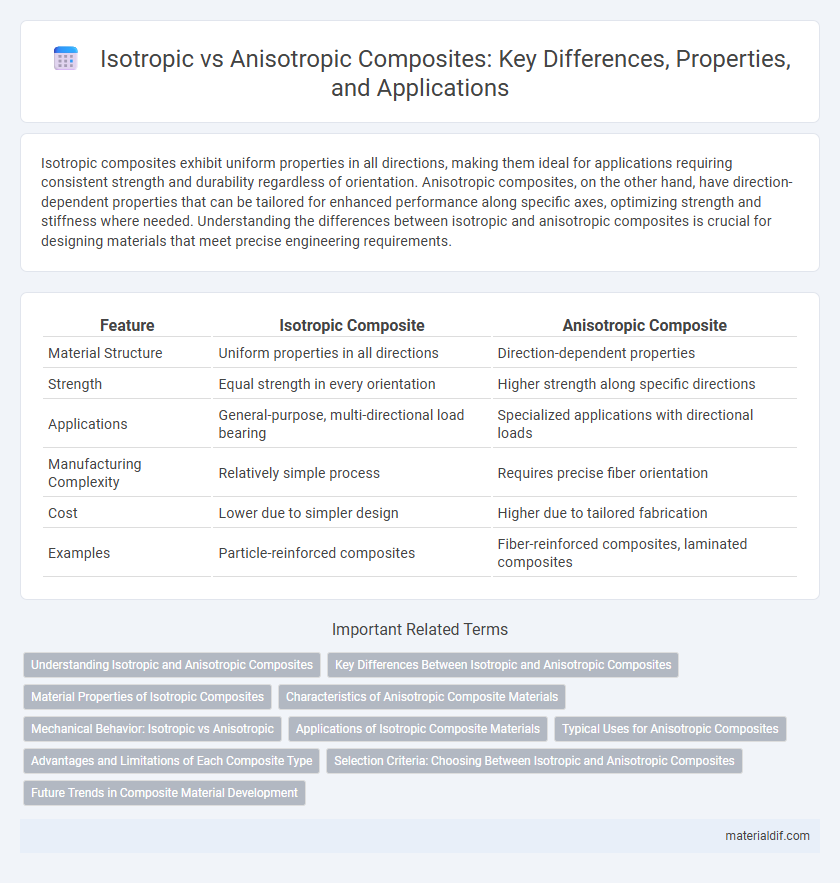

Isotropic composites exhibit uniform properties in all directions, making them ideal for applications requiring consistent strength and durability regardless of orientation. Anisotropic composites, on the other hand, have direction-dependent properties that can be tailored for enhanced performance along specific axes, optimizing strength and stiffness where needed. Understanding the differences between isotropic and anisotropic composites is crucial for designing materials that meet precise engineering requirements.

Table of Comparison

| Feature | Isotropic Composite | Anisotropic Composite |

|---|---|---|

| Material Structure | Uniform properties in all directions | Direction-dependent properties |

| Strength | Equal strength in every orientation | Higher strength along specific directions |

| Applications | General-purpose, multi-directional load bearing | Specialized applications with directional loads |

| Manufacturing Complexity | Relatively simple process | Requires precise fiber orientation |

| Cost | Lower due to simpler design | Higher due to tailored fabrication |

| Examples | Particle-reinforced composites | Fiber-reinforced composites, laminated composites |

Understanding Isotropic and Anisotropic Composites

Isotropic composites exhibit uniform mechanical properties in all directions, making them ideal for applications requiring consistent strength and stiffness. Anisotropic composites possess direction-dependent properties, allowing engineers to tailor materials for specific load-bearing requirements by aligning fibers or particles. Understanding the differences in stress distribution and deformation behavior between isotropic and anisotropic composites is critical for optimizing performance in aerospace, automotive, and civil engineering structures.

Key Differences Between Isotropic and Anisotropic Composites

Isotropic composites exhibit uniform mechanical properties in all directions due to their homogeneous structure, while anisotropic composites display direction-dependent properties resulting from aligned fibers or layers. The key differences lie in their stiffness, strength, and thermal expansion characteristics, with isotropic composites offering consistent behavior and anisotropic composites providing tailored performance along specific orientations. These distinctions influence material selection for applications requiring either uniform response or directional strength optimization.

Material Properties of Isotropic Composites

Isotropic composites exhibit uniform material properties in all directions, ensuring consistent mechanical performance such as tensile strength, elasticity, and thermal expansion. This uniformity results from the random orientation of reinforcing fibers or particles within the matrix, providing predictable behavior under multi-axial loading conditions. As a result, isotropic composites are highly suitable for applications demanding equal strength and stiffness across various stress orientations.

Characteristics of Anisotropic Composite Materials

Anisotropic composite materials exhibit direction-dependent properties, meaning their mechanical, thermal, and electrical behaviors vary along different axes due to fiber orientation or layering. This directional behavior enhances performance in specific load-bearing directions, making anisotropic composites ideal for advanced aerospace, automotive, and structural applications. Their tailored stiffness and strength optimize weight efficiency while requiring careful analysis to predict behavior under multi-axial stresses.

Mechanical Behavior: Isotropic vs Anisotropic

Isotropic composites exhibit uniform mechanical behavior in all directions due to their homogeneous microstructure, making them ideal for applications requiring consistent strength and stiffness. Anisotropic composites display directional dependence in mechanical properties, often resulting in enhanced performance along specific axes but reduced properties in others. Understanding these differences is crucial for optimizing load-bearing capacity and fatigue resistance in engineering designs.

Applications of Isotropic Composite Materials

Isotropic composite materials, characterized by uniform mechanical properties in all directions, are widely used in aerospace components, automotive parts, and sports equipment where consistent strength and durability are critical. Their homogeneous nature makes them ideal for applications requiring predictable load distribution and resistance to multidirectional stresses. Industries leverage isotropic composites to achieve enhanced performance in lightweight structural frameworks and protective gear.

Typical Uses for Anisotropic Composites

Anisotropic composites are commonly used in aerospace and automotive industries where directional strength and stiffness are critical for performance and safety. These composites are ideal for load-bearing structures, such as aircraft wings and car chassis, because their fibers are aligned to withstand specific stress directions. Their tailored mechanical properties enable enhanced durability and weight savings in high-performance applications.

Advantages and Limitations of Each Composite Type

Isotropic composites offer uniform mechanical properties in all directions, making them ideal for applications requiring consistent strength, but their performance may be limited under directional loads. Anisotropic composites provide superior strength and stiffness along specific orientations due to aligned fibers, enhancing performance in targeted stress directions but resulting in weaker properties perpendicular to fiber alignment. The choice between isotropic and anisotropic composites depends on balancing the need for multidirectional uniformity versus directional optimization in structural applications.

Selection Criteria: Choosing Between Isotropic and Anisotropic Composites

Selection between isotropic and anisotropic composites depends on the specific mechanical properties required for the application, such as uniform strength distribution versus directional strength optimization. Isotropic composites offer consistent performance in all directions due to their homogeneous structure, making them ideal for components subjected to multi-directional stresses. Anisotropic composites provide tailored stiffness and strength along defined axes, suitable for applications demanding high load-bearing capacity in specific orientations.

Future Trends in Composite Material Development

Future trends in composite material development emphasize enhancing mechanical performance and sustainability by integrating nanomaterials in both isotropic and anisotropic composites. Advances in manufacturing technologies like additive manufacturing and automated fiber placement enable precise control over fiber orientation, optimizing properties in anisotropic composites for aerospace and automotive applications. Research on self-healing composites and bio-based resins drives innovation toward eco-friendly isotropic composites with improved durability and recyclability.

Isotropic Composite vs Anisotropic Composite Infographic

materialdif.com

materialdif.com