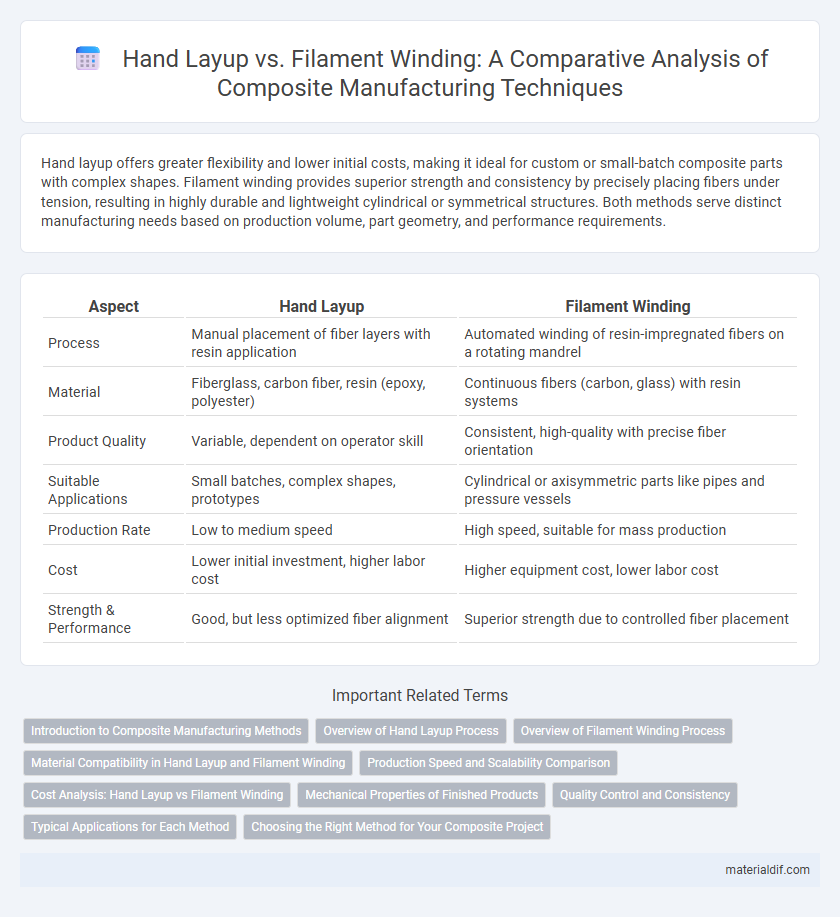

Hand layup offers greater flexibility and lower initial costs, making it ideal for custom or small-batch composite parts with complex shapes. Filament winding provides superior strength and consistency by precisely placing fibers under tension, resulting in highly durable and lightweight cylindrical or symmetrical structures. Both methods serve distinct manufacturing needs based on production volume, part geometry, and performance requirements.

Table of Comparison

| Aspect | Hand Layup | Filament Winding |

|---|---|---|

| Process | Manual placement of fiber layers with resin application | Automated winding of resin-impregnated fibers on a rotating mandrel |

| Material | Fiberglass, carbon fiber, resin (epoxy, polyester) | Continuous fibers (carbon, glass) with resin systems |

| Product Quality | Variable, dependent on operator skill | Consistent, high-quality with precise fiber orientation |

| Suitable Applications | Small batches, complex shapes, prototypes | Cylindrical or axisymmetric parts like pipes and pressure vessels |

| Production Rate | Low to medium speed | High speed, suitable for mass production |

| Cost | Lower initial investment, higher labor cost | Higher equipment cost, lower labor cost |

| Strength & Performance | Good, but less optimized fiber alignment | Superior strength due to controlled fiber placement |

Introduction to Composite Manufacturing Methods

Hand layup and filament winding are two primary composite manufacturing methods, each offering distinct advantages in material distribution and structural performance. Hand layup involves manually placing reinforcement fibers into a mold and impregnating them with resin, making it suitable for complex shapes and low-volume production. Filament winding automates fiber placement by wrapping continuous strands around a rotating mandrel, optimizing fiber alignment and strength in cylindrical or tubular components.

Overview of Hand Layup Process

Hand layup is a manual composite manufacturing process where layers of reinforcement fibers, typically fiberglass or carbon fiber, are placed into a mold and impregnated with resin by brush or roller. This technique allows precise control over fiber placement and resin content, making it suitable for low-volume production and complex geometries. The process involves curing at ambient or elevated temperatures to form strong, lightweight composite structures ideal for marine, automotive, and aerospace applications.

Overview of Filament Winding Process

Filament winding is a manufacturing process that involves continuous fiber reinforcement, typically carbon, glass, or aramid fibers, which are impregnated with resin and precisely wound onto a rotating mandrel to form composite structures. This automated technique allows for high fiber volume fractions and optimized fiber orientations, resulting in strong, lightweight, and highly durable cylindrical components such as pipes, tanks, and pressure vessels. The process provides superior control over fiber placement compared to hand layup, enhancing structural integrity and consistency in composite production.

Material Compatibility in Hand Layup and Filament Winding

Hand layup offers versatile material compatibility, allowing the use of various fibers such as glass, carbon, and aramid with different resin systems like epoxy, polyester, and vinyl ester. Filament winding primarily uses continuous fibers, predominantly carbon and glass, optimizing mechanical properties when combined with thermosetting resins like epoxy and phenolic. The choice of material compatibility in both processes critically influences composite strength, durability, and performance in aerospace, automotive, and marine applications.

Production Speed and Scalability Comparison

Hand layup offers slower production speed due to its manual process, limiting scalability for large-volume manufacturing. Filament winding enables faster, automated production with consistent quality, making it more suitable for high-volume, large-scale composite part fabrication. Scalability in filament winding is enhanced by programmable machines that reduce labor intensity and increase throughput.

Cost Analysis: Hand Layup vs Filament Winding

Hand layup offers lower initial tooling and equipment costs, making it cost-effective for small production runs and prototyping. Filament winding requires higher upfront investment in automated machinery and tooling but delivers reduced labor costs and faster production rates for large-scale manufacturing. Overall, filament winding can achieve lower unit costs in high-volume applications, while hand layup remains economical for low-volume or customized composites.

Mechanical Properties of Finished Products

Hand layup composites typically exhibit lower mechanical strength and stiffness compared to filament wound composites due to less uniform fiber distribution and potential for air voids. Filament winding enhances tensile strength and impact resistance by precisely controlling fiber orientation and resin content, resulting in superior structural performance. These mechanical advantages make filament winding ideal for high-stress applications such as pressure vessels and aerospace components.

Quality Control and Consistency

Hand layup relies heavily on operator skill, often leading to variability in thickness and resin distribution, which can affect the final composite quality. Filament winding offers superior quality control by automating fiber placement and tension, ensuring consistent layer thickness and optimal resin impregnation. This process reduces defects like voids and delamination, making filament winding ideal for high-performance, repeatable composite structures.

Typical Applications for Each Method

Hand layup is commonly used for low-volume production in automotive body panels, marine boat hulls, and custom architectural components due to its flexibility and cost-effectiveness. Filament winding excels in high-strength, cylindrical structures such as pressure vessels, pipes, and aerospace rocket motor casings by providing uniform fiber alignment and superior mechanical properties. Both methods serve distinct industrial applications based on production scale, mechanical requirements, and geometric complexity.

Choosing the Right Method for Your Composite Project

Hand layup offers greater design flexibility and cost-effectiveness for small-scale composite projects requiring complex shapes. Filament winding provides superior mechanical strength and consistency, ideal for cylindrical structures such as pipes and pressure vessels. Selecting the appropriate method depends on project size, shape complexity, mechanical requirements, and budget constraints.

Hand Layup vs Filament Winding Infographic

materialdif.com

materialdif.com