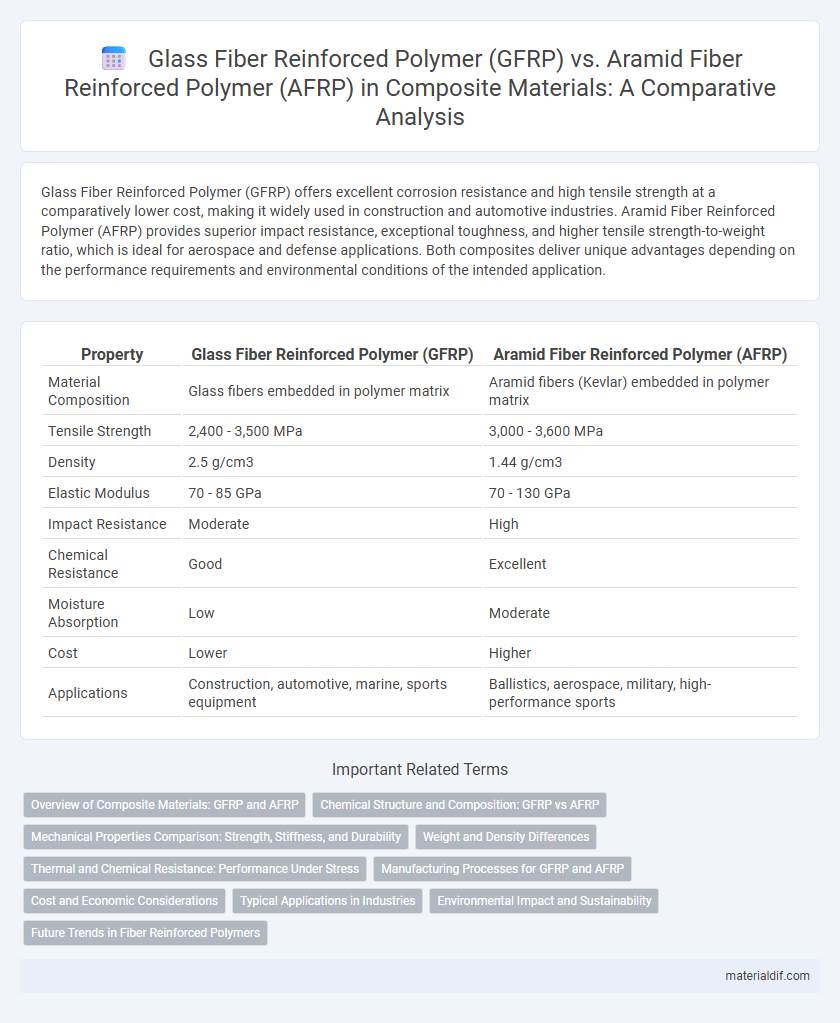

Glass Fiber Reinforced Polymer (GFRP) offers excellent corrosion resistance and high tensile strength at a comparatively lower cost, making it widely used in construction and automotive industries. Aramid Fiber Reinforced Polymer (AFRP) provides superior impact resistance, exceptional toughness, and higher tensile strength-to-weight ratio, which is ideal for aerospace and defense applications. Both composites deliver unique advantages depending on the performance requirements and environmental conditions of the intended application.

Table of Comparison

| Property | Glass Fiber Reinforced Polymer (GFRP) | Aramid Fiber Reinforced Polymer (AFRP) |

|---|---|---|

| Material Composition | Glass fibers embedded in polymer matrix | Aramid fibers (Kevlar) embedded in polymer matrix |

| Tensile Strength | 2,400 - 3,500 MPa | 3,000 - 3,600 MPa |

| Density | 2.5 g/cm3 | 1.44 g/cm3 |

| Elastic Modulus | 70 - 85 GPa | 70 - 130 GPa |

| Impact Resistance | Moderate | High |

| Chemical Resistance | Good | Excellent |

| Moisture Absorption | Low | Moderate |

| Cost | Lower | Higher |

| Applications | Construction, automotive, marine, sports equipment | Ballistics, aerospace, military, high-performance sports |

Overview of Composite Materials: GFRP and AFRP

Glass Fiber Reinforced Polymer (GFRP) composites feature glass fibers embedded in a polymer matrix, offering high tensile strength, excellent corrosion resistance, and cost-effectiveness for structural applications. Aramid Fiber Reinforced Polymer (AFRP) composites utilize aramid fibers such as Kevlar, providing superior impact resistance, lightweight strength, and enhanced fatigue durability compared to GFRP. Both composites serve critical roles in aerospace, automotive, and civil engineering, with GFRP favored for general purpose load-bearing and AFRP chosen for high-performance impact and abrasion environments.

Chemical Structure and Composition: GFRP vs AFRP

Glass Fiber Reinforced Polymer (GFRP) consists of silica-based glass fibers embedded in a polymer matrix, providing high tensile strength and chemical resistance due to the amorphous structure of glass fibers. Aramid Fiber Reinforced Polymer (AFRP) utilizes aramid fibers, composed of aromatic polyamide chains with benzene rings linked by amide bonds, delivering superior toughness, thermal stability, and impact resistance. The key chemical distinction lies in GFRP's inorganic silica fibers versus AFRP's organic, aromatic polymer fibers, influencing their mechanical properties and chemical durability in composite applications.

Mechanical Properties Comparison: Strength, Stiffness, and Durability

Glass Fiber Reinforced Polymer (GFRP) exhibits higher stiffness and excellent durability but generally lower tensile strength compared to Aramid Fiber Reinforced Polymer (AFRP), which offers superior strength-to-weight ratio and impact resistance. AFRP materials provide enhanced toughness and energy absorption with moderate stiffness, making them ideal for dynamic load applications. Both composites maintain corrosion resistance and fatigue performance, but the choice depends on specific load-bearing and environmental requirements.

Weight and Density Differences

Glass Fiber Reinforced Polymer (GFRP) typically has a higher density ranging from 2.5 to 2.6 g/cm3 compared to Aramid Fiber Reinforced Polymer (AFRP), which generally exhibits a lower density around 1.4 g/cm3, making AFRP significantly lighter. This weight difference impacts applications where weight reduction is critical, such as aerospace and automotive industries. The lower density of AFRP contributes to improved fuel efficiency and easier handling without compromising strength.

Thermal and Chemical Resistance: Performance Under Stress

Glass Fiber Reinforced Polymer (GFRP) exhibits superior thermal stability withstanding temperatures up to 550degF, making it highly resistant to heat-induced degradation. Aramid Fiber Reinforced Polymer (AFRP) offers exceptional chemical resistance, particularly against solvents and acids, while maintaining performance under thermal stress up to 400degF. The choice between GFRP and AFRP depends on specific environmental factors, where GFRP excels in high-temperature applications and AFRP is preferred for chemically aggressive conditions.

Manufacturing Processes for GFRP and AFRP

Glass Fiber Reinforced Polymer (GFRP) is commonly manufactured through processes such as pultrusion, hand lay-up, and filament winding, which allow for cost-effective production and versatility in shape and size. In contrast, Aramid Fiber Reinforced Polymer (AFRP) typically involves more specialized manufacturing techniques like resin transfer molding (RTM) and vacuum-assisted resin infusion (VARI) to manage the fibers' sensitivity to moisture and abrasion. Both GFRP and AFRP require careful control of curing conditions and fiber alignment to optimize mechanical properties in their respective composite components.

Cost and Economic Considerations

Glass Fiber Reinforced Polymer (GFRP) offers a significantly lower production cost compared to Aramid Fiber Reinforced Polymer (AFRP), making it more economically viable for large-scale applications. While AFRP provides superior strength-to-weight ratios and enhanced impact resistance, its higher material cost and complex manufacturing process contribute to increased overall expenses. Lifecycle cost analysis often favors GFRP due to its balance of performance and affordability, especially in budget-sensitive projects.

Typical Applications in Industries

Glass Fiber Reinforced Polymer (GFRP) is predominantly used in construction, automotive, and marine industries due to its cost-effectiveness, high tensile strength, and corrosion resistance. Aramid Fiber Reinforced Polymer (AFRP) finds typical applications in aerospace, military, and sporting goods sectors, leveraging its exceptional impact resistance, lightweight properties, and thermal stability. Both materials enhance performance in composites but serve distinct roles based on industry-specific durability and weight requirements.

Environmental Impact and Sustainability

Glass Fiber Reinforced Polymer (GFRP) typically has a higher environmental impact due to energy-intensive production processes and challenges in recycling, contributing to greater carbon emissions and landfill waste. In contrast, Aramid Fiber Reinforced Polymer (AFRP) offers improved durability and longer service life, reducing the need for frequent replacements and lowering overall resource consumption. Sustainable applications of AFRP prioritize lifecycle efficiency and enhanced recyclability compared to traditional GFRP composites.

Future Trends in Fiber Reinforced Polymers

Glass Fiber Reinforced Polymer (GFRP) and Aramid Fiber Reinforced Polymer (AFRP) are pivotal in advancing composite materials, with future trends highlighting enhanced performance through hybridization and nanotechnology integration. Innovations focus on improving durability, impact resistance, and environmental sustainability by incorporating bio-based resins and smart sensing capabilities. Emerging applications in aerospace, automotive, and civil infrastructure drive research towards multifunctional composites with tailored mechanical properties and lifecycle optimization.

Glass Fiber Reinforced Polymer (GFRP) vs Aramid Fiber Reinforced Polymer (AFRP) Infographic

materialdif.com

materialdif.com