Sheet Molding Compound (SMC) offers superior strength and surface finish compared to Bulk Molding Compound (BMC) due to its continuous fiber reinforcement and controlled thickness. BMC excels in complex, intricate shapes with short fiber reinforcements, making it ideal for high-volume, detailed parts. Both materials provide excellent electrical insulation and corrosion resistance, but the choice depends on specific mechanical and design requirements.

Table of Comparison

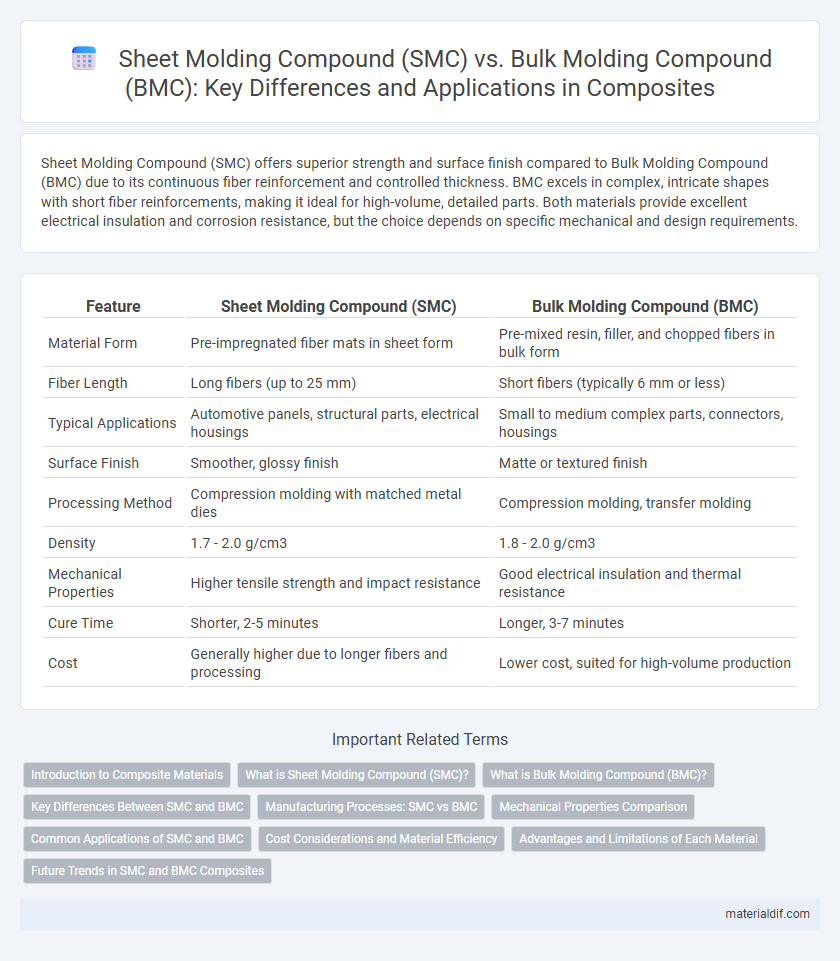

| Feature | Sheet Molding Compound (SMC) | Bulk Molding Compound (BMC) |

|---|---|---|

| Material Form | Pre-impregnated fiber mats in sheet form | Pre-mixed resin, filler, and chopped fibers in bulk form |

| Fiber Length | Long fibers (up to 25 mm) | Short fibers (typically 6 mm or less) |

| Typical Applications | Automotive panels, structural parts, electrical housings | Small to medium complex parts, connectors, housings |

| Surface Finish | Smoother, glossy finish | Matte or textured finish |

| Processing Method | Compression molding with matched metal dies | Compression molding, transfer molding |

| Density | 1.7 - 2.0 g/cm3 | 1.8 - 2.0 g/cm3 |

| Mechanical Properties | Higher tensile strength and impact resistance | Good electrical insulation and thermal resistance |

| Cure Time | Shorter, 2-5 minutes | Longer, 3-7 minutes |

| Cost | Generally higher due to longer fibers and processing | Lower cost, suited for high-volume production |

Introduction to Composite Materials

Sheet Molding Compound (SMC) and Bulk Molding Compound (BMC) are key polymer composite materials widely used in the manufacturing of high-strength, lightweight components. SMC features a fiber-reinforced resin paste spread into thin sheets, offering superior surface finish and dimensional stability, while BMC consists of a thicker, moldable dough-like mixture with shorter fibers, ideal for complex shapes and electrical insulation. Both materials exemplify the versatility of composite materials by combining thermosetting resins with glass fibers to achieve enhanced mechanical properties and corrosion resistance.

What is Sheet Molding Compound (SMC)?

Sheet Molding Compound (SMC) is a fiber-reinforced polyester composite material consisting of a mixture of resin, chopped glass fibers, fillers, and additives, pre-impregnated into a sheet form. SMC offers high strength-to-weight ratio, excellent surface finish, and superior corrosion resistance, making it ideal for automotive, aerospace, and electrical applications. Its processing involves compression molding, allowing complex geometries with consistent mechanical properties and reduced cycle times.

What is Bulk Molding Compound (BMC)?

Bulk Molding Compound (BMC) is a pre-mixed composite material consisting of thermosetting resins, fillers, and chopped glass fibers, designed for molding complex shapes with high strength and excellent electrical insulation. It offers superior dimensional stability and higher filler content compared to Sheet Molding Compound (SMC), making it ideal for smaller, intricate components in automotive and electrical industries. BMC's high flow properties and faster curing cycles enable efficient mass production with consistent quality and mechanical performance.

Key Differences Between SMC and BMC

Sheet Molding Compound (SMC) offers superior surface finish and greater fiber length, resulting in enhanced mechanical properties compared to Bulk Molding Compound (BMC), which uses shorter fibers and is better suited for complex, detailed parts. SMC typically enables thicker, larger parts with improved toughness and impact resistance, while BMC provides greater moldability for intricate shapes due to its lower viscosity and shorter curing cycles. The choice between SMC and BMC depends on application requirements such as part geometry, mechanical strength, surface quality, and production volume.

Manufacturing Processes: SMC vs BMC

Sheet Molding Compound (SMC) is produced by spreading a mixture of resin, fibers, and fillers onto a carrier film, then partially curing it into a thick sheet, allowing for precise control of fiber orientation and thickness during compression molding. Bulk Molding Compound (BMC) involves mixing fibers and resin into a pliable paste that is used immediately in molding, resulting in shorter cycle times but less control over fiber alignment and part uniformity. SMC's manufacturing process enables larger, more complex parts with high structural performance, while BMC is suited for smaller, intricate components requiring rapid production.

Mechanical Properties Comparison

Sheet Molding Compound (SMC) exhibits superior mechanical properties compared to Bulk Molding Compound (BMC), including higher tensile strength and enhanced impact resistance due to its continuous fiber alignment and uniform thickness. SMC typically achieves tensile strengths in the range of 80-120 MPa, whereas BMC generally offers lower tensile strength around 50-90 MPa, limiting its application in high-stress environments. The improved flexural modulus and fatigue resistance of SMC make it preferable for automotive and aerospace components requiring durability and lightweight performance.

Common Applications of SMC and BMC

Sheet Molding Compound (SMC) is commonly used in automotive body panels, electrical housings, and structural parts due to its excellent surface finish and high strength-to-weight ratio. Bulk Molding Compound (BMC) finds applications in complex, small to medium-sized components such as electrical connectors, appliance parts, and plumbing fittings, benefiting from its ease of molding and dimensional stability. Both materials serve critical roles in the transportation, electrical, and construction industries, optimizing performance and manufacturability.

Cost Considerations and Material Efficiency

Sheet Molding Compound (SMC) typically offers greater material efficiency compared to Bulk Molding Compound (BMC) due to its uniform fiber distribution and ability to be molded into thinner, lighter parts, reducing waste and raw material usage. In terms of cost, SMC generally has higher initial tooling expenses but benefits from lower labor costs and faster cycle times, leading to reduced overall production costs for high-volume manufacturing. BMC presents lower upfront tooling costs but can result in higher material waste and longer processing times, impacting its cost-effectiveness in large-scale applications.

Advantages and Limitations of Each Material

Sheet Molding Compound (SMC) offers superior dimensional stability, higher fiber content, and excellent surface finish, making it ideal for large, complex parts requiring tight tolerances. Bulk Molding Compound (BMC) provides greater versatility in molding intricate shapes with high electrical insulation properties but typically exhibits lower mechanical strength and surface quality compared to SMC. Limitations of SMC include higher material costs and longer curing times, whereas BMC challenges involve potential fiber orientation issues and increased shrinkage during molding.

Future Trends in SMC and BMC Composites

Future trends in Sheet Molding Compound (SMC) and Bulk Molding Compound (BMC) composites emphasize enhanced material formulations with increased use of bio-based resins and recycled fibers to improve sustainability. Advanced processing techniques such as automation and AI-driven quality control are expanding production capabilities while reducing costs and defects. Innovations in hybrid composites combining SMC and BMC with nanomaterials are driving superior mechanical properties and application versatility in automotive, aerospace, and construction industries.

Sheet Molding Compound (SMC) vs Bulk Molding Compound (BMC) Infographic

materialdif.com

materialdif.com