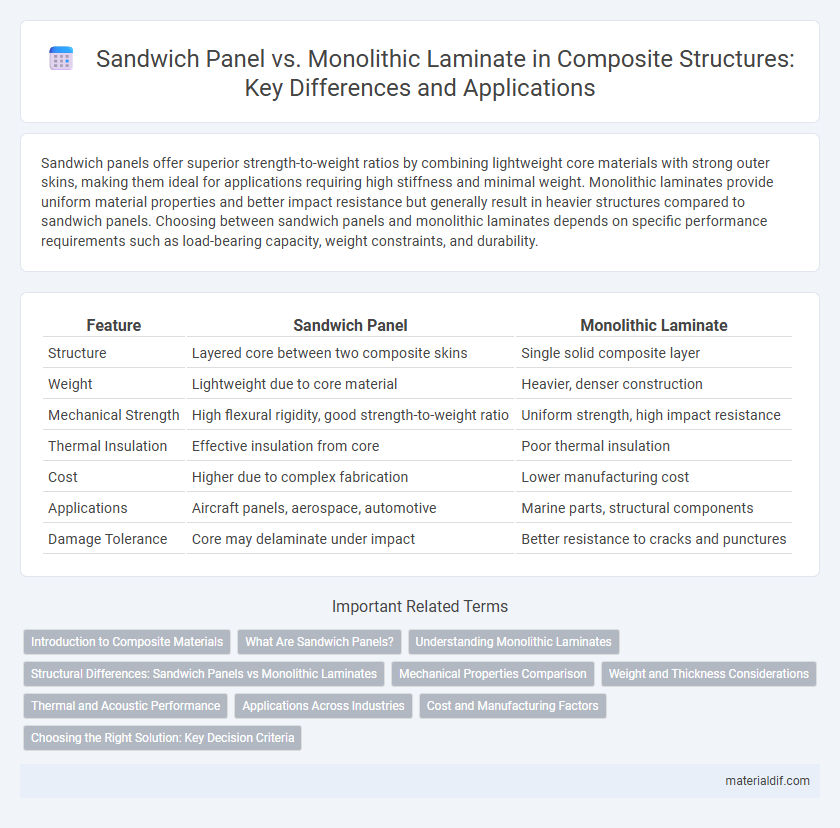

Sandwich panels offer superior strength-to-weight ratios by combining lightweight core materials with strong outer skins, making them ideal for applications requiring high stiffness and minimal weight. Monolithic laminates provide uniform material properties and better impact resistance but generally result in heavier structures compared to sandwich panels. Choosing between sandwich panels and monolithic laminates depends on specific performance requirements such as load-bearing capacity, weight constraints, and durability.

Table of Comparison

| Feature | Sandwich Panel | Monolithic Laminate |

|---|---|---|

| Structure | Layered core between two composite skins | Single solid composite layer |

| Weight | Lightweight due to core material | Heavier, denser construction |

| Mechanical Strength | High flexural rigidity, good strength-to-weight ratio | Uniform strength, high impact resistance |

| Thermal Insulation | Effective insulation from core | Poor thermal insulation |

| Cost | Higher due to complex fabrication | Lower manufacturing cost |

| Applications | Aircraft panels, aerospace, automotive | Marine parts, structural components |

| Damage Tolerance | Core may delaminate under impact | Better resistance to cracks and punctures |

Introduction to Composite Materials

Sandwich panels consist of two strong outer layers bonded to a lightweight core, offering high stiffness-to-weight ratios ideal for aerospace and automotive applications. Monolithic laminates are made from multiple layers of composite fibers impregnated with resin, providing uniform mechanical properties and excellent strength-to-weight performance. Both composites enhance structural efficiency by optimizing material distribution to meet specific load requirements.

What Are Sandwich Panels?

Sandwich panels are composite structures consisting of two thin, strong face sheets bonded to a lightweight core, providing high stiffness-to-weight ratios and excellent thermal insulation. Common core materials include foam, honeycomb, or balsa wood, enhancing strength while minimizing weight. These panels are widely used in aerospace, construction, and automotive industries for their superior load-bearing capacity and durability compared to monolithic laminates.

Understanding Monolithic Laminates

Monolithic laminates consist of multiple layers of reinforcement fibers bonded together with a single matrix material, offering uniform mechanical properties and enhanced durability. These laminates provide superior impact resistance and structural integrity compared to sandwich panels, which use a lightweight core with outer composite skins. Understanding the fiber orientation and matrix type in monolithic laminates is crucial for optimizing strength, stiffness, and performance in aerospace and automotive applications.

Structural Differences: Sandwich Panels vs Monolithic Laminates

Sandwich panels feature a core material--often foam or honeycomb--bonded between two thin, stiff face sheets, providing high stiffness-to-weight ratios and enhanced impact resistance. Monolithic laminates consist of multiple layers of fiber-reinforced material consolidated into a single, solid structure, offering superior uniform strength but increased weight compared to sandwich designs. The core in sandwich panels significantly reduces bending stress by separating the face sheets, whereas monolithic laminates rely on the total laminate thickness for structural integrity.

Mechanical Properties Comparison

Sandwich panels exhibit superior flexural stiffness and strength-to-weight ratios compared to monolithic laminates due to their core-to-face architecture, which enables efficient load distribution and enhances bending performance. Monolithic laminates typically provide higher in-plane strength and impact resistance but are heavier and less efficient in resisting out-of-plane stresses. Mechanical properties such as shear modulus, tensile strength, and fatigue resistance vary significantly, with sandwich panels excelling in lightweight structural applications requiring high bending rigidity.

Weight and Thickness Considerations

Sandwich panels typically offer a superior strength-to-weight ratio compared to monolithic laminates, resulting in lighter structures with reduced thickness. The core material in sandwich panels minimizes weight without compromising stiffness, making them ideal for aerospace and automotive applications where weight savings are critical. Monolithic laminates usually require greater thickness to achieve comparable strength, leading to heavier components that can impact performance.

Thermal and Acoustic Performance

Sandwich panels exhibit superior thermal insulation due to their core materials, such as foam or honeycomb, which reduce heat transfer effectively compared to monolithic laminates. Acoustic performance in sandwich panels is enhanced by the core's ability to absorb and dampen sound waves, resulting in better noise reduction than solid monolithic laminates. Thermal conductivity values for sandwich panels typically range between 0.02 to 0.05 W/mK, significantly lower than monolithic laminates, which contributes to improved energy efficiency in building applications.

Applications Across Industries

Sandwich panels dominate industries like aerospace, automotive, and construction due to their superior strength-to-weight ratio and thermal insulation properties. Monolithic laminates find extensive use in applications requiring high impact resistance and structural integrity, such as wind turbine blades and marine vessels. Both materials optimize performance based on specific industry demands, with sandwich panels excelling in lightweight structural applications and monolithic laminates preferred for durability and toughness.

Cost and Manufacturing Factors

Sandwich panels typically offer lower manufacturing costs due to faster production and less material usage compared to monolithic laminates, which require more labor-intensive processes and higher raw material expenses. Cost-efficiency in sandwich panels arises from their layered structure, combining lightweight cores with thin skins, reducing overall weight and material costs while maintaining strength. Monolithic laminates excel in applications demanding uniform strength, but their continuous fiber construction results in longer curing times and increased labor intensity, driving up total production costs.

Choosing the Right Solution: Key Decision Criteria

Selecting between sandwich panels and monolithic laminates depends on factors such as mechanical strength, weight requirements, and thermal insulation properties. Sandwich panels offer superior stiffness-to-weight ratios and enhanced thermal performance due to their core materials, making them ideal for aerospace and automotive applications. Monolithic laminates provide more uniform strength and better impact resistance, suited for applications demanding high durability and simpler manufacturing processes.

Sandwich panel vs Monolithic laminate Infographic

materialdif.com

materialdif.com