Cellophane and cellulose acetate differ primarily in their chemical composition and environmental impact, with cellophane being a biodegradable film made from regenerated cellulose, while cellulose acetate is a synthetic polymer derived from cellulose treated with acetic anhydride. Cellophane offers excellent moisture barrier properties and breathability, making it ideal for packaging fresh produce, whereas cellulose acetate is more commonly used in applications requiring increased durability and transparency, such as photographic films and eyewear. Choosing between these materials depends on the balance between sustainability needs and specific functional requirements in packaging or product design.

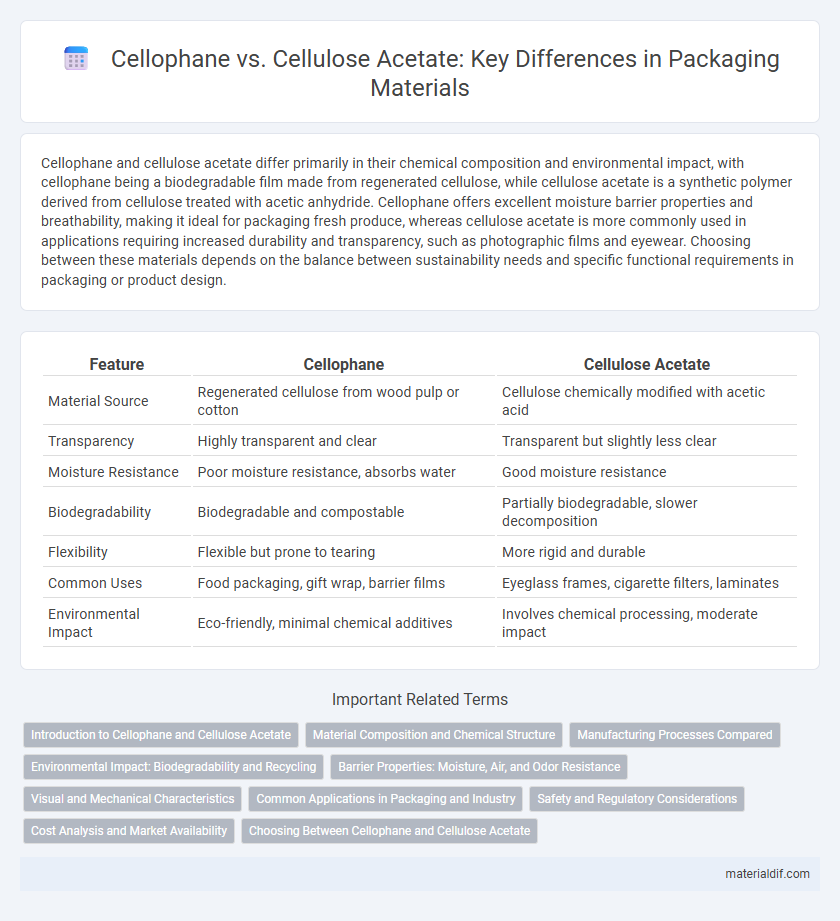

Table of Comparison

| Feature | Cellophane | Cellulose Acetate |

|---|---|---|

| Material Source | Regenerated cellulose from wood pulp or cotton | Cellulose chemically modified with acetic acid |

| Transparency | Highly transparent and clear | Transparent but slightly less clear |

| Moisture Resistance | Poor moisture resistance, absorbs water | Good moisture resistance |

| Biodegradability | Biodegradable and compostable | Partially biodegradable, slower decomposition |

| Flexibility | Flexible but prone to tearing | More rigid and durable |

| Common Uses | Food packaging, gift wrap, barrier films | Eyeglass frames, cigarette filters, laminates |

| Environmental Impact | Eco-friendly, minimal chemical additives | Involves chemical processing, moderate impact |

Introduction to Cellophane and Cellulose Acetate

Cellophane is a transparent, thin film made from regenerated cellulose, renowned for its biodegradability and moisture resistance, primarily used in food packaging and wrapping. Cellulose acetate, derived from cellulose through acetylation, offers greater chemical stability and clarity, making it ideal for photographic films, eyeglass frames, and coatings. Both materials originate from cellulose but differ in chemical composition and applications, with cellophane emphasizing eco-friendliness and cellulose acetate focusing on durability and versatility.

Material Composition and Chemical Structure

Cellophane is a thin, transparent film made from regenerated cellulose derived from wood pulp or cotton fibers, characterized by its polysaccharide structure composed of glucose units linked by b-1,4-glycosidic bonds. In contrast, cellulose acetate is a semi-synthetic polymer produced by acetylating cellulose with acetic anhydride, introducing acetyl functional groups that modify the cellulose backbone and increase hydrophobicity and chemical resistance. The chemical structure of cellophane retains native cellulose hydroxyl groups, providing biodegradability and permeability, while cellulose acetate's acetyl substitution alters physical properties, making it less permeable and more durable for specific industrial applications.

Manufacturing Processes Compared

Cellophane is produced through a viscose process where cellulose is dissolved in alkali and carbon disulfide to form a viscous solution, which is then extruded and regenerated into transparent film. In contrast, cellulose acetate manufacturing involves acetylation of cellulose with acetic anhydride, followed by solvent-based dissolution and casting into sheets or films. These distinct chemical treatments result in cellophane being more biodegradable, while cellulose acetate offers superior moisture resistance and film stability.

Environmental Impact: Biodegradability and Recycling

Cellophane, made from regenerated cellulose, is fully biodegradable and compostable, breaking down naturally within weeks under composting conditions. In contrast, cellulose acetate, a modified cellulose derivative, is less biodegradable due to its chemical acetylation, often requiring industrial recycling processes to reduce environmental impact. Recycling cellophane is challenging because it is typically coated with plastic films, while cellulose acetate films are more amenable to solvent-based recycling methods.

Barrier Properties: Moisture, Air, and Odor Resistance

Cellophane exhibits superior moisture barrier properties due to its dense polymer structure, effectively preventing water vapor transmission compared to cellulose acetate. In contrast, cellulose acetate provides better air and odor resistance because of its hydrophobic acetyl groups, making it ideal for packaging sensitive products. The choice between cellophane and cellulose acetate depends on specific barrier requirements, with cellophane favored for moisture-sensitive applications and cellulose acetate preferred for enhanced odor and air barrier performance.

Visual and Mechanical Characteristics

Cellophane exhibits high transparency with a glossy finish, offering excellent clarity compared to cellulose acetate, which tends to have a slightly tinted appearance and lower optical clarity. Mechanically, cellophane is more brittle and prone to tearing under stress, whereas cellulose acetate demonstrates greater flexibility and durability, making it preferred for applications requiring repeated bending. The moisture barrier properties also differ, with cellulose acetate providing better resistance to water vapor than cellophane.

Common Applications in Packaging and Industry

Cellophane is widely used in packaging for its biodegradability and moisture barrier properties, making it ideal for food wrapping and gift packaging. Cellulose acetate, known for its superior clarity and flexibility, is commonly applied in photographic films, cigarette filters, and specialty packaging where durability and aesthetics are prioritized. Both materials serve distinct roles in packaging and industry, with cellophane favored for eco-friendly solutions and cellulose acetate chosen for technical performance requirements.

Safety and Regulatory Considerations

Cellophane is a biodegradable film made from regenerated cellulose, offering excellent safety profiles and compliance with FDA food contact regulations. Cellulose acetate, though derived from cellulose, involves chemical modification that may raise concerns about plasticizers and solvent residues, impacting its regulatory acceptance for direct food contact. In contrast, cellophane's natural composition minimizes potential toxicity, making it a preferred choice in applications demanding stringent safety and environmental standards.

Cost Analysis and Market Availability

Cellophane, derived from regenerated cellulose, generally costs less to produce than cellulose acetate due to simpler manufacturing processes and lower raw material expenses. Market availability of cellophane remains strong, especially in food packaging, benefiting from biodegradability and consumer demand for eco-friendly materials, whereas cellulose acetate is more specialized, often used in photographic films and cigarette filters. Cost analysis reveals cellophane's competitive pricing supports widespread use, while cellulose acetate's higher cost limits its applications to niche markets with specific performance requirements.

Choosing Between Cellophane and Cellulose Acetate

Choosing between cellophane and cellulose acetate depends on desired properties such as biodegradability, clarity, and moisture resistance. Cellophane is a biodegradable film made from regenerated cellulose, offering excellent breathability and suitability for food packaging, whereas cellulose acetate provides higher water resistance and better dimensional stability but is less biodegradable. Understanding these material characteristics helps optimize packaging performance and environmental impact based on specific application needs.

Cellophane vs Cellulose Acetate Infographic

materialdif.com

materialdif.com