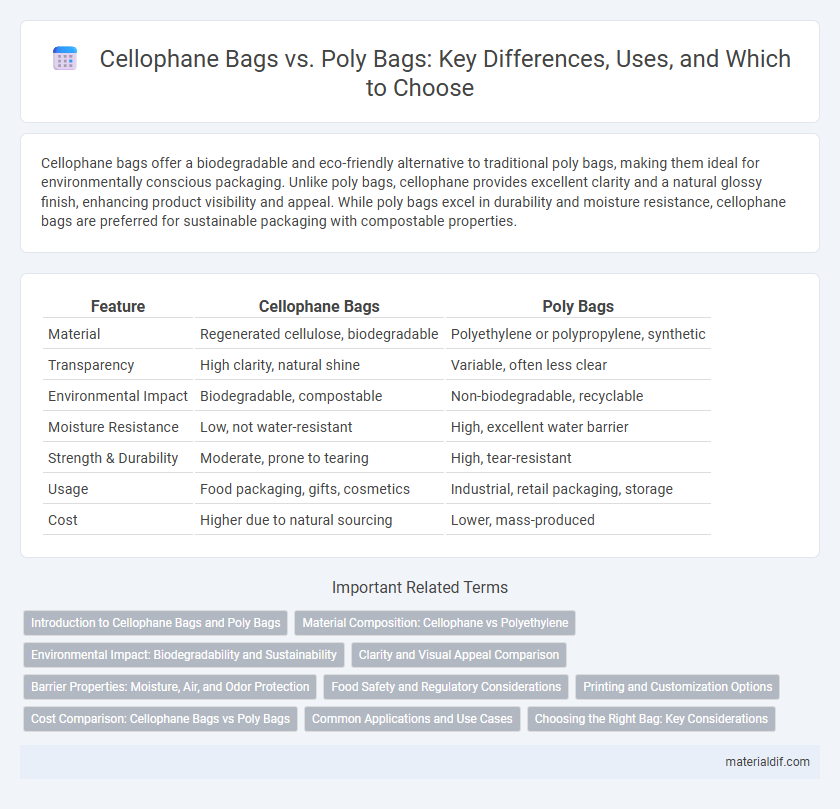

Cellophane bags offer a biodegradable and eco-friendly alternative to traditional poly bags, making them ideal for environmentally conscious packaging. Unlike poly bags, cellophane provides excellent clarity and a natural glossy finish, enhancing product visibility and appeal. While poly bags excel in durability and moisture resistance, cellophane bags are preferred for sustainable packaging with compostable properties.

Table of Comparison

| Feature | Cellophane Bags | Poly Bags |

|---|---|---|

| Material | Regenerated cellulose, biodegradable | Polyethylene or polypropylene, synthetic |

| Transparency | High clarity, natural shine | Variable, often less clear |

| Environmental Impact | Biodegradable, compostable | Non-biodegradable, recyclable |

| Moisture Resistance | Low, not water-resistant | High, excellent water barrier |

| Strength & Durability | Moderate, prone to tearing | High, tear-resistant |

| Usage | Food packaging, gifts, cosmetics | Industrial, retail packaging, storage |

| Cost | Higher due to natural sourcing | Lower, mass-produced |

Introduction to Cellophane Bags and Poly Bags

Cellophane bags, made from regenerated cellulose, offer excellent moisture and gas barrier properties, making them ideal for food packaging and gift wrapping. Poly bags, typically crafted from polyethylene or polypropylene, provide superior durability and resistance to chemicals, commonly used in industrial and retail packaging. Understanding the material differences highlights cellophane's eco-friendliness and clarity versus poly bags' strength and flexibility.

Material Composition: Cellophane vs Polyethylene

Cellophane bags are made from regenerated cellulose, a natural polymer derived from wood pulp, enabling them to be biodegradable and compostable, which appeals to eco-conscious consumers. Poly bags are typically made from polyethylene, a synthetic polymer derived from petroleum, known for its durability, flexibility, and moisture resistance but limited biodegradability. The material composition difference impacts environmental footprint, with cellophane offering sustainable disposal options while polyethylene provides superior physical protection for products.

Environmental Impact: Biodegradability and Sustainability

Cellophane bags are derived from cellulose, a natural polymer, making them biodegradable and compostable within weeks under industrial conditions, whereas poly bags are typically made from non-renewable petroleum-based plastics that persist in the environment for hundreds of years. The sustainability of cellophane bags is enhanced by their lower carbon footprint during production and their ability to break down without leaving toxic residues, contrasting with poly bags which contribute significantly to plastic pollution and microplastic contamination. Choosing cellophane over poly bags reduces landfill accumulation and supports circular economy principles due to cellophane's renewable sourcing and eco-friendly degradation properties.

Clarity and Visual Appeal Comparison

Cellophane bags offer superior clarity and a more natural, glossy finish compared to poly bags, enhancing product visibility and visual appeal. Unlike poly bags, which often have a slightly cloudy or matte appearance, cellophane is fully transparent, providing an attractive display that highlights the product inside. This crystal-clear quality makes cellophane bags ideal for retail packaging where presentation and consumer appeal are critical.

Barrier Properties: Moisture, Air, and Odor Protection

Cellophane bags offer superior moisture barrier properties due to their dense cellulose structure, effectively preventing water vapor transmission compared to poly bags. However, poly bags typically provide enhanced air and odor barrier protection, utilizing their polyethylene or polypropylene layers to seal in freshness and block external contaminants. For applications requiring strong moisture resistance combined with moderate air and odor protection, selecting the appropriate material depends on the specific storage and packaging environment.

Food Safety and Regulatory Considerations

Cellophane bags, made from cellulose, are biodegradable and naturally breathable, enhancing food safety by reducing moisture buildup and bacterial growth compared to poly bags made from polyethylene. Regulatory standards, such as FDA compliance for food contact materials, often favor cellophane for its chemical-free composition and lower risk of leaching harmful substances into food products. Poly bags may require additional additives or plasticizers that pose potential regulatory challenges, making cellophane bags a safer, eco-friendly choice for food packaging.

Printing and Customization Options

Cellophane bags offer superior printing clarity and vibrant color reproduction due to their smooth, non-porous surface, making them ideal for high-quality custom logos and intricate designs. Poly bags, typically made from polyethylene, support basic printing options with more limited color vibrancy and resolution, often resulting in less detailed graphics. Businesses seeking premium customization for product packaging often prefer cellophane bags to enhance brand visibility and aesthetic appeal.

Cost Comparison: Cellophane Bags vs Poly Bags

Cellophane bags typically cost more than poly bags due to their biodegradable material and production process, which demands higher quality cellulose. Poly bags, made from inexpensive polyethylene resin, offer a more cost-effective solution for bulk packaging and general use. When budget constraints are paramount, poly bags provide a lower upfront expense, but cellophane bags may justify the premium through environmental benefits and market appeal.

Common Applications and Use Cases

Cellophane bags offer excellent moisture resistance and clarity, making them ideal for packaging food items like baked goods, candies, and fresh produce where visibility and freshness are essential. Poly bags, made from polyethylene, are more durable and flexible, commonly used for industrial packaging, garment covers, and heavy-duty storage where tear resistance and flexibility are prioritized. Both materials are widely used in retail and food industries but serve distinct purposes based on their properties and application requirements.

Choosing the Right Bag: Key Considerations

Cellophane bags offer superior moisture resistance and biodegradable properties compared to poly bags, making them ideal for eco-conscious packaging needs. Poly bags excel in durability and cost-effectiveness, suitable for heavy-duty or budget-sensitive applications. Choosing the right bag depends on factors such as environmental impact, product protection, and budget constraints.

Cellophane Bags vs Poly Bags Infographic

materialdif.com

materialdif.com