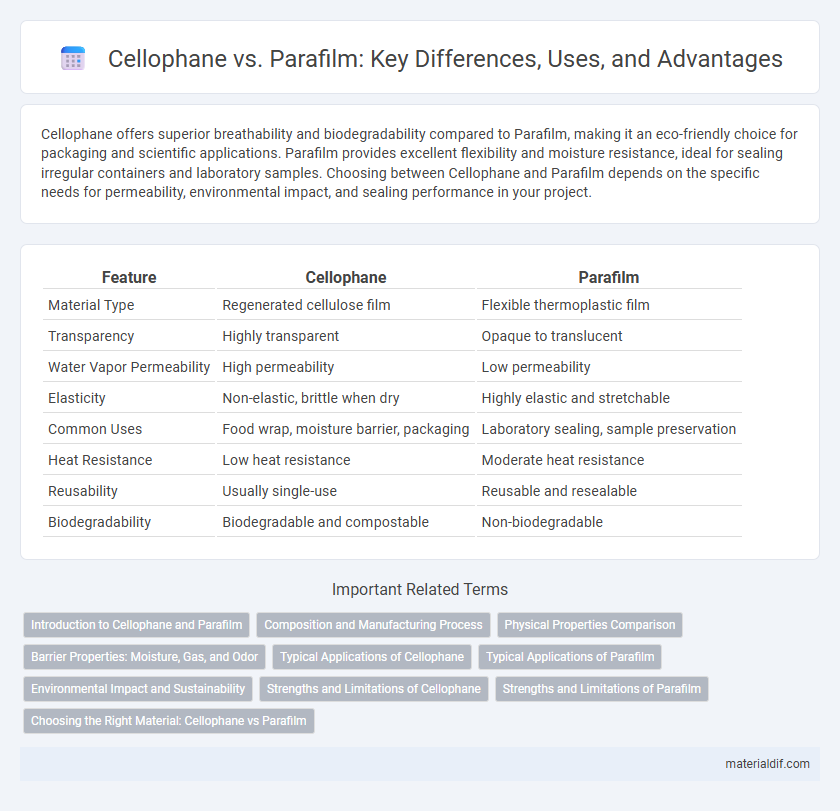

Cellophane offers superior breathability and biodegradability compared to Parafilm, making it an eco-friendly choice for packaging and scientific applications. Parafilm provides excellent flexibility and moisture resistance, ideal for sealing irregular containers and laboratory samples. Choosing between Cellophane and Parafilm depends on the specific needs for permeability, environmental impact, and sealing performance in your project.

Table of Comparison

| Feature | Cellophane | Parafilm |

|---|---|---|

| Material Type | Regenerated cellulose film | Flexible thermoplastic film |

| Transparency | Highly transparent | Opaque to translucent |

| Water Vapor Permeability | High permeability | Low permeability |

| Elasticity | Non-elastic, brittle when dry | Highly elastic and stretchable |

| Common Uses | Food wrap, moisture barrier, packaging | Laboratory sealing, sample preservation |

| Heat Resistance | Low heat resistance | Moderate heat resistance |

| Reusability | Usually single-use | Reusable and resealable |

| Biodegradability | Biodegradable and compostable | Non-biodegradable |

Introduction to Cellophane and Parafilm

Cellophane is a thin, transparent film made from cellulose, known for its excellent moisture barrier and breathability, commonly used for food packaging and preserving freshness. Parafilm is a flexible, stretchable plastic wrap composed of a blend of waxes and polyolefins, widely utilized in laboratories for sealing containers due to its superior airtight and chemical-resistant properties. Cellophane offers biodegradability and clarity, whereas Parafilm provides durability and elasticity, making each suitable for distinct applications based on packaging or sealing requirements.

Composition and Manufacturing Process

Cellophane is a thin, transparent film made from cellulose derived from wood pulp or cotton fibers, produced through a viscose process involving chemical treatments to convert cellulose into a workable film. Parafilm, however, is a synthetic, flexible film composed primarily of polyolefins and waxes, manufactured through extrusion and calendaring processes that create a stretchable sealing material. The cellulose base of Cellophane provides biodegradability and breathability, while Parafilm's synthetic composition offers superior elasticity and moisture resistance for laboratory sealing applications.

Physical Properties Comparison

Cellophane exhibits high tensile strength, excellent moisture permeability, and biodegradability, making it suitable for packaging that requires breathability and environmental sustainability. Parafilm, a flexible, stretchable thermoplastic, offers superior elasticity, excellent moisture and gas barrier properties, and chemical resistance, ideal for sealing laboratory containers. The physical properties of cellophane and parafilm dictate their specific applications, with cellophane emphasizing transparency and eco-friendliness, while parafilm focuses on flexibility and sealing performance.

Barrier Properties: Moisture, Gas, and Odor

Cellophane offers superior moisture barrier properties compared to Parafilm, making it ideal for packaging applications requiring low moisture permeability. Parafilm exhibits higher gas permeability but provides a better seal against odors due to its pliability and self-sealing characteristics. The choice between Cellophane and Parafilm depends on the specific requirements for moisture resistance, gas exchange, and odor containment in the packaging environment.

Typical Applications of Cellophane

Cellophane is commonly used in food packaging, including wrapping fresh produce, confectionery, and baked goods, due to its excellent oxygen and moisture barrier properties that help preserve freshness. It is also widely applied in gift wrapping and floral arrangements, offering a transparent, biodegradable alternative to plastic films. Unlike Parafilm, which is favored for laboratory sealing and protection, Cellophane's primary role is in commercial and consumer packaging where visibility and environmental sustainability are key.

Typical Applications of Parafilm

Parafilm is commonly used in laboratories for sealing and protecting vessels such as petri dishes, test tubes, and flasks due to its flexible, stretchable, and self-sealing properties. Unlike cellophane, Parafilm provides an effective barrier against moisture and contaminants, making it ideal for applications requiring airtight seals and sample preservation. Its versatility extends to horticulture for grafting and wrapping, where its waterproof and pliable nature ensures secure coverage without compromising breathability.

Environmental Impact and Sustainability

Cellophane is a biodegradable, plant-based film derived from cellulose, making it more environmentally friendly compared to Parafilm, which is petroleum-based and non-biodegradable. Cellophane's production and disposal have a lower carbon footprint and less contribution to plastic pollution, supporting sustainability efforts. In contrast, Parafilm's synthetic composition leads to persistence in landfills and challenges in recycling, raising concerns about long-term environmental impact.

Strengths and Limitations of Cellophane

Cellophane offers excellent breathability and moisture resistance, making it ideal for food packaging that requires freshness and visibility. Its natural cellulose composition ensures biodegradability, appealing to eco-conscious consumers, but it lacks elasticity and tear resistance compared to Parafilm. Unlike Parafilm's versatile stretch and sealing properties, cellophane is more prone to punctures and less suitable for airtight sealing applications.

Strengths and Limitations of Parafilm

Parafilm offers superior flexibility and stretchability compared to cellophane, making it ideal for sealing irregular containers and preventing air and moisture exchange effectively. However, Parafilm has limited heat resistance and can degrade under high temperatures, whereas cellophane provides better thermal stability. The semi-permeable nature of Parafilm allows for controlled gas exchange but is not suitable for applications requiring complete moisture barriers, a limitation cellophane can overcome with its low permeability properties.

Choosing the Right Material: Cellophane vs Parafilm

Cellophane offers superior breathability and biodegradability, making it ideal for applications requiring moisture exchange and eco-friendliness. Parafilm provides excellent flexibility, stretchability, and airtight sealing, preferred for laboratory use and sealing containers to prevent contamination. Choosing between cellophane and parafilm depends on the need for environmental sustainability versus enhanced sealing and durability.

Cellophane vs Parafilm Infographic

materialdif.com

materialdif.com