Cellophane, a cellulose-based film, is biodegradable and derived from natural plant fibers, offering an eco-friendly alternative to synthetic polymer films made from petroleum-based materials. Unlike synthetic films, cellophane provides excellent breathability and moisture resistance while maintaining transparency and flexibility. Its natural composition makes cellophane a sustainable choice with less environmental impact compared to non-biodegradable synthetic polymer films.

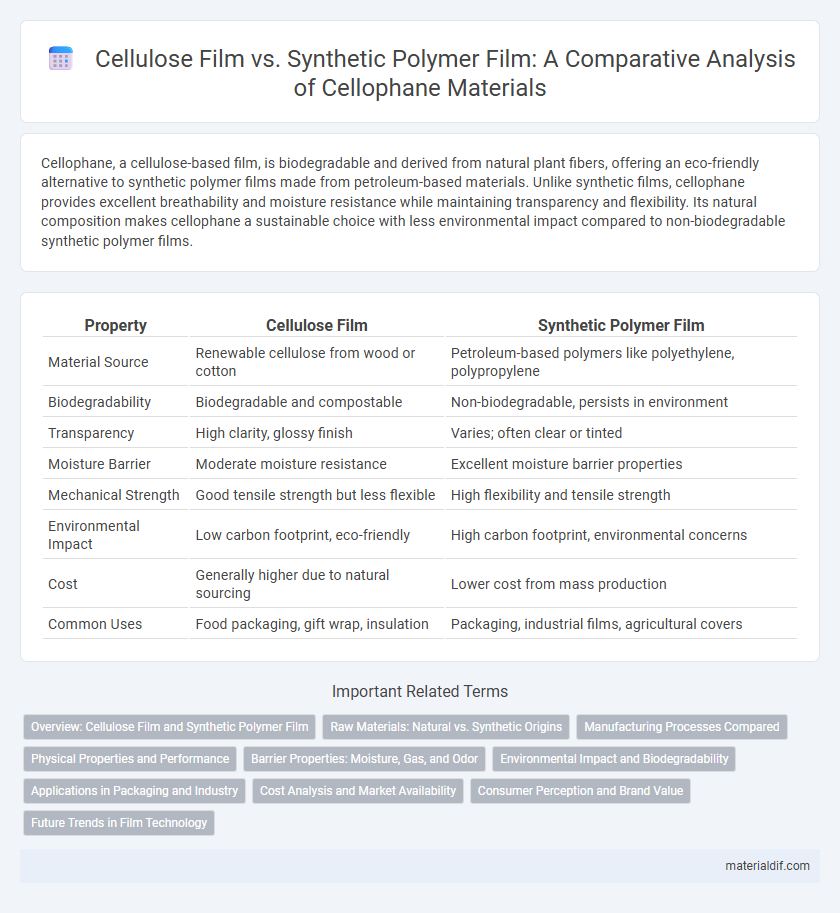

Table of Comparison

| Property | Cellulose Film | Synthetic Polymer Film |

|---|---|---|

| Material Source | Renewable cellulose from wood or cotton | Petroleum-based polymers like polyethylene, polypropylene |

| Biodegradability | Biodegradable and compostable | Non-biodegradable, persists in environment |

| Transparency | High clarity, glossy finish | Varies; often clear or tinted |

| Moisture Barrier | Moderate moisture resistance | Excellent moisture barrier properties |

| Mechanical Strength | Good tensile strength but less flexible | High flexibility and tensile strength |

| Environmental Impact | Low carbon footprint, eco-friendly | High carbon footprint, environmental concerns |

| Cost | Generally higher due to natural sourcing | Lower cost from mass production |

| Common Uses | Food packaging, gift wrap, insulation | Packaging, industrial films, agricultural covers |

Overview: Cellulose Film and Synthetic Polymer Film

Cellulose film, derived from natural cellulose fibers, offers excellent biodegradability and oxygen permeability, making it ideal for eco-friendly packaging applications. Synthetic polymer films, such as polyethylene and polypropylene, provide superior mechanical strength, moisture resistance, and cost-effectiveness but lack biodegradability. The choice between cellulose film and synthetic polymer film depends on specific packaging needs, balancing environmental impact with functional performance.

Raw Materials: Natural vs. Synthetic Origins

Cellulose film is derived from natural raw materials such as wood pulp or cotton fibers, making it biodegradable and renewable. In contrast, synthetic polymer films are produced from petrochemical-based materials like polyethylene and polypropylene, which are non-renewable and contribute to plastic pollution. The natural origin of cellulose film supports sustainability efforts, whereas synthetic films prioritize durability and cost-efficiency.

Manufacturing Processes Compared

Cellulose film is produced primarily from regenerated cellulose derived from wood pulp or cotton fibers, involving processes like viscose or lyocell methods that dissolve cellulose and reconstitute it into thin, biodegradable sheets. Synthetic polymer films such as polyethylene or polypropylene are manufactured through polymerization of petroleum-based monomers followed by extrusion or casting techniques, resulting in non-biodegradable, petrochemical-derived films. The manufacturing of cellulose film emphasizes renewable raw materials and eco-friendly solvents, contrasting with synthetic films that rely on fossil fuels and energy-intensive processes.

Physical Properties and Performance

Cellulose film, derived from natural cellulose fibers, exhibits excellent biodegradability, high tensile strength, and superior oxygen and aroma barrier properties compared to synthetic polymer films like polyethylene and polyester. Synthetic polymer films often provide greater moisture resistance and flexibility but lack the environmental benefits and natural breathability of cellulose films. The choice between cellulose and synthetic films depends on application-specific requirements such as sustainability, mechanical strength, and barrier performance.

Barrier Properties: Moisture, Gas, and Odor

Cellulose film exhibits superior moisture barrier properties due to its hydrophilic nature, effectively limiting water vapor transmission compared to many synthetic polymer films. However, synthetic polymer films like polyethylene and polypropylene often provide enhanced gas barrier capabilities, especially against oxygen and carbon dioxide, due to their dense molecular structures. In terms of odor barrier, synthetic films generally outperform cellulose film by preventing the permeation of volatile compounds, making them preferable for packaging applications requiring stringent odor control.

Environmental Impact and Biodegradability

Cellulose film, derived from natural cellulose fibers, offers superior environmental benefits due to its biodegradability and compostability, breaking down into non-toxic organic matter within weeks under natural conditions. Synthetic polymer films, typically made from petroleum-based plastics like polyethylene or polypropylene, persist in the environment for decades, contributing significantly to plastic pollution and microplastic contamination. The renewable sourcing and eco-friendly decomposition of cellulose film make it a preferable alternative to synthetic polymer films, aligning with sustainable packaging and waste reduction goals.

Applications in Packaging and Industry

Cellulose film, derived from natural cellulose fibers, is biodegradable and commonly used in food packaging for its breathability and moisture resistance, making it ideal for fresh produce and confectionery. Synthetic polymer films such as polyethylene and polypropylene offer superior strength, chemical resistance, and flexibility, widely applied in industrial packaging, shrink wraps, and heavy-duty protective layers. The choice between cellulose and synthetic polymer films hinges on environmental impact considerations and specific packaging requirements like durability, transparency, and barrier properties.

Cost Analysis and Market Availability

Cellulose film generally incurs higher production costs due to its natural cellulose source and more intricate manufacturing process compared to synthetic polymer films, which benefit from large-scale petrochemical production. Market availability favors synthetic polymer films, given their widespread use in packaging and lower price points, making them dominant in global supply chains. Despite this, cellulose films retain niche market appeal for eco-conscious brands seeking biodegradable alternatives, even at a premium cost.

Consumer Perception and Brand Value

Consumers often perceive cellulose film as a more eco-friendly and biodegradable packaging option compared to synthetic polymer films, which enhances brand value through sustainability credentials. Brands using cellulose film can leverage its natural origin and compostability to appeal to environmentally conscious customers, fostering trust and loyalty. In contrast, synthetic polymer films, despite offering superior barrier properties, may be viewed negatively due to environmental concerns, potentially impacting brand reputation.

Future Trends in Film Technology

Cellulose film, derived from natural cellulose fibers, offers superior biodegradability and compostability compared to synthetic polymer films like polyethylene and polypropylene, which are predominantly fossil-fuel-based and less environmentally friendly. Future trends in film technology emphasize the development of hybrid films combining cellulose with biodegradable polymers to enhance mechanical strength and barrier properties while maintaining eco-friendliness. Innovations in bio-based coatings and nanotechnology aim to improve moisture resistance and transparency, positioning cellulose films as sustainable alternatives in packaging and specialty applications.

Cellulose Film vs Synthetic Polymer Film Infographic

materialdif.com

materialdif.com