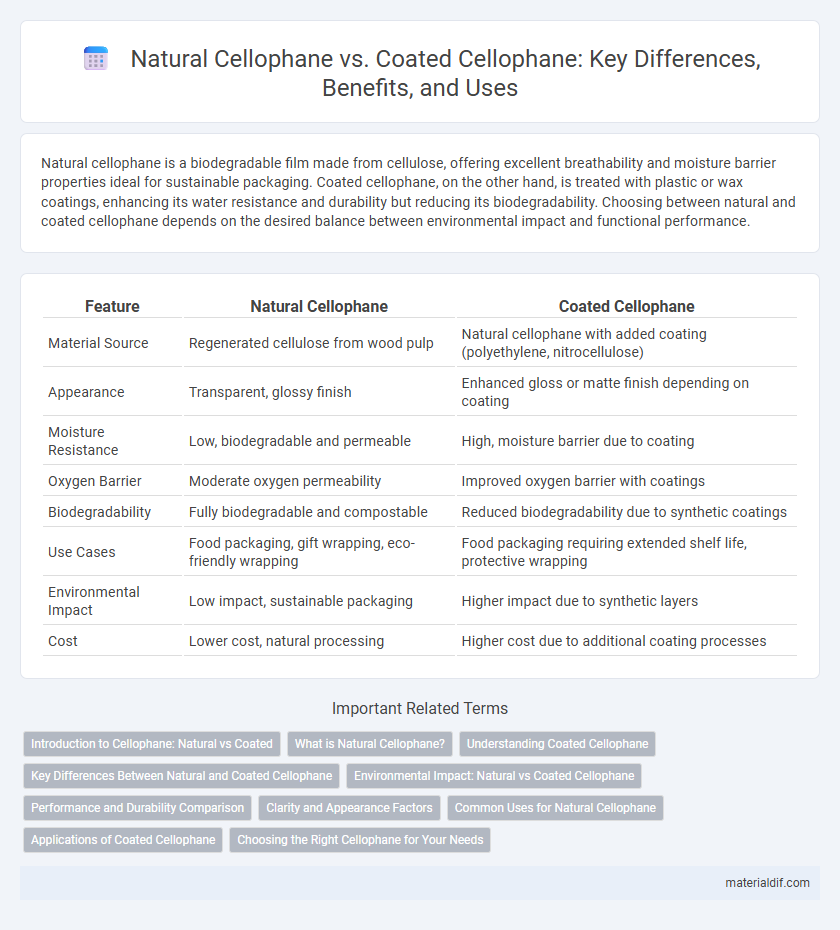

Natural cellophane is a biodegradable film made from cellulose, offering excellent breathability and moisture barrier properties ideal for sustainable packaging. Coated cellophane, on the other hand, is treated with plastic or wax coatings, enhancing its water resistance and durability but reducing its biodegradability. Choosing between natural and coated cellophane depends on the desired balance between environmental impact and functional performance.

Table of Comparison

| Feature | Natural Cellophane | Coated Cellophane |

|---|---|---|

| Material Source | Regenerated cellulose from wood pulp | Natural cellophane with added coating (polyethylene, nitrocellulose) |

| Appearance | Transparent, glossy finish | Enhanced gloss or matte finish depending on coating |

| Moisture Resistance | Low, biodegradable and permeable | High, moisture barrier due to coating |

| Oxygen Barrier | Moderate oxygen permeability | Improved oxygen barrier with coatings |

| Biodegradability | Fully biodegradable and compostable | Reduced biodegradability due to synthetic coatings |

| Use Cases | Food packaging, gift wrapping, eco-friendly wrapping | Food packaging requiring extended shelf life, protective wrapping |

| Environmental Impact | Low impact, sustainable packaging | Higher impact due to synthetic layers |

| Cost | Lower cost, natural processing | Higher cost due to additional coating processes |

Introduction to Cellophane: Natural vs Coated

Natural cellophane is a biodegradable film made from cellulose derived from wood pulp or cotton, known for its transparency, breathability, and eco-friendly properties. Coated cellophane incorporates additional layers such as nitrocellulose or polyethylene to enhance moisture resistance, durability, and sealing capabilities, often used in food packaging. Understanding the differences between natural and coated cellophane is crucial for selecting appropriate materials based on environmental impact and functional requirements.

What is Natural Cellophane?

Natural cellophane is a transparent film made from regenerated cellulose derived from wood pulp or cotton fibers, known for its biodegradable and compostable properties. It offers excellent moisture permeability and breathability, making it ideal for food packaging applications that require freshness preservation without trapping moisture. Unlike coated cellophane, natural cellophane is uncoated, allowing it to maintain its environmental friendliness and reduce plastic waste.

Understanding Coated Cellophane

Coated cellophane enhances natural cellophane by applying a thin polymer layer, improving moisture resistance and durability while retaining biodegradability and transparency. This coating enables increased barrier properties against oils and gases, making coated cellophane ideal for food packaging applications needing extended shelf life. The combination of natural cellulose base and synthetic coating creates a versatile, eco-friendly material widely used in sustainable packaging solutions.

Key Differences Between Natural and Coated Cellophane

Natural cellophane is derived from cellulose and is biodegradable, offering a transparent, breathable, and moisture-permeable packaging option. Coated cellophane, on the other hand, incorporates layers of materials such as nitrocellulose or polyethylene, enhancing its barrier properties by making it water-resistant and less permeable to gases. These coatings improve durability and shelf life but reduce biodegradability compared to the natural, eco-friendly alternative.

Environmental Impact: Natural vs Coated Cellophane

Natural cellophane, made from cellulose derived from wood pulp or cotton fibers, is biodegradable and compostable, significantly reducing its environmental footprint. Coated cellophane typically incorporates synthetic polymers or plasticizers, which hinder biodegradability and contribute to plastic pollution. The use of natural cellophane supports sustainable packaging solutions by minimizing plastic waste and promoting a circular economy.

Performance and Durability Comparison

Natural cellophane offers excellent breathability and biodegradability but has limited moisture resistance and lower tensile strength compared to coated cellophane. Coated cellophane, enhanced with resin or wax layers, significantly improves moisture barrier properties and durability, making it ideal for packaging items requiring longer shelf life. Performance-wise, coated cellophane withstands wear and tear better under varying environmental conditions, ensuring enhanced protection and product preservation.

Clarity and Appearance Factors

Natural cellophane offers superior clarity due to its pure cellulose composition, making it ideal for transparent packaging where visibility is crucial. Coated cellophane, treated with materials like nitrocellulose or wax, enhances durability and moisture resistance but may slightly reduce transparency and gloss. The choice between natural and coated cellophane depends on balancing the need for pristine appearance against functional protection requirements.

Common Uses for Natural Cellophane

Natural cellophane, made from cellulose derived from wood or cotton, is commonly used in food packaging to preserve freshness due to its moisture-resistant properties and biodegradability. It serves as an eco-friendly alternative for wrapping candies, baked goods, and fresh produce, maintaining product visibility while providing a breathable barrier. Unlike coated cellophane, which has added plastic layers for enhanced durability, natural cellophane is preferred for applications prioritizing compostability and reduced environmental impact.

Applications of Coated Cellophane

Coated cellophane is extensively used in food packaging due to its enhanced moisture resistance and improved barrier properties against oils and greases, making it ideal for wrapping bakery items, confectioneries, and fresh produce. Its coating allows for excellent printability, enabling vibrant designs and branding on packaging materials, which is beneficial in retail displays. Moreover, coated cellophane finds applications in photographic films and decorative packaging where durability and clarity are essential.

Choosing the Right Cellophane for Your Needs

Natural cellophane is biodegradable and allows for excellent breathability, making it ideal for food packaging that requires moisture control and environmental sustainability. Coated cellophane features a thin polymer layer that enhances its water resistance and gloss, providing superior protection for items exposed to moisture or requiring a polished appearance. Selecting the right cellophane depends on the balance between eco-friendliness and functional demands such as durability and barrier properties.

Natural Cellophane vs Coated Cellophane Infographic

materialdif.com

materialdif.com