Cellophane offers superior biodegradability compared to LDPE, making it an eco-friendly alternative for packaging. While LDPE is a widely used plastic known for its flexibility and moisture resistance, it poses significant environmental challenges due to its slow decomposition rate. Cellophane's natural cellulose base provides excellent breathability and clarity, which LDPE cannot match, making it ideal for food wrapping and sustainable product packaging.

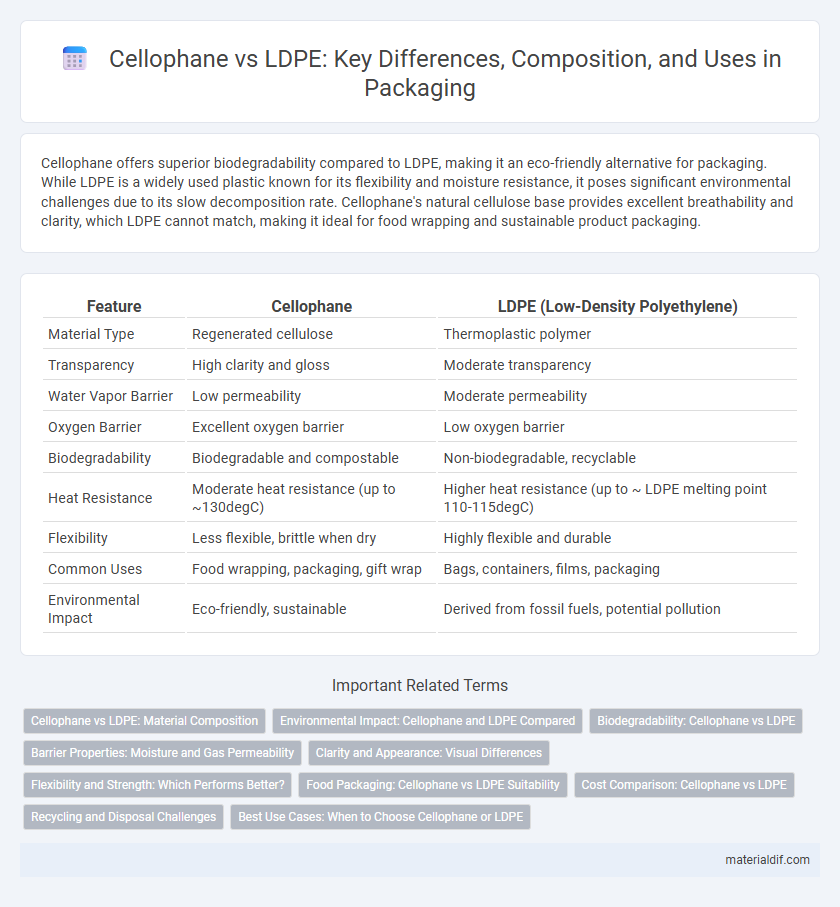

Table of Comparison

| Feature | Cellophane | LDPE (Low-Density Polyethylene) |

|---|---|---|

| Material Type | Regenerated cellulose | Thermoplastic polymer |

| Transparency | High clarity and gloss | Moderate transparency |

| Water Vapor Barrier | Low permeability | Moderate permeability |

| Oxygen Barrier | Excellent oxygen barrier | Low oxygen barrier |

| Biodegradability | Biodegradable and compostable | Non-biodegradable, recyclable |

| Heat Resistance | Moderate heat resistance (up to ~130degC) | Higher heat resistance (up to ~ LDPE melting point 110-115degC) |

| Flexibility | Less flexible, brittle when dry | Highly flexible and durable |

| Common Uses | Food wrapping, packaging, gift wrap | Bags, containers, films, packaging |

| Environmental Impact | Eco-friendly, sustainable | Derived from fossil fuels, potential pollution |

Cellophane vs LDPE: Material Composition

Cellophane is composed of regenerated cellulose derived from natural cellulose fibers, making it biodegradable and compostable, whereas LDPE (Low-Density Polyethylene) is a synthetic polymer made from petrochemicals, characterized by its flexibility and resistance to moisture. Cellophane's molecular structure provides excellent breathability and a natural barrier to oils and greases, contrasting with LDPE's dense, impermeable polymer matrix designed for moisture and chemical resistance. The distinct material compositions influence their environmental impact, with cellophane favoring sustainability and LDPE offering durability and water resistance in packaging applications.

Environmental Impact: Cellophane and LDPE Compared

Cellophane, derived from cellulose, is biodegradable and compostable, breaking down naturally within weeks to months, while LDPE (Low-Density Polyethylene), a petroleum-based plastic, can persist in the environment for hundreds of years. Cellophane production typically results in fewer carbon emissions compared to LDPE's fossil fuel-dependent manufacturing process. The environmental impact of disposing LDPE includes microplastic pollution and landfill accumulation, whereas cellophane's organic composition promotes reduced ecological footprint and improved sustainability.

Biodegradability: Cellophane vs LDPE

Cellophane is a biodegradable film derived from cellulose, breaking down naturally within weeks to months in composting conditions. LDPE (low-density polyethylene), a petroleum-based plastic, resists biodegradation and can persist in the environment for hundreds of years. This key difference makes cellophane a more eco-friendly packaging option compared to LDPE for reducing plastic pollution.

Barrier Properties: Moisture and Gas Permeability

Cellophane exhibits superior barrier properties compared to LDPE, featuring significantly lower moisture vapor transmission rates which effectively reduce water permeability. Its dense cellulose structure also provides enhanced gas barrier capabilities, limiting oxygen and carbon dioxide permeability crucial for food preservation. In contrast, LDPE offers higher moisture and gas permeability, making it less ideal for applications requiring stringent barrier performance.

Clarity and Appearance: Visual Differences

Cellophane offers superior clarity and a glossy, natural sheen that enhances product visibility, making it ideal for premium packaging and displays. In contrast, LDPE has a more matte finish with moderate transparency, which can slightly obscure the packaged contents. This visual difference makes cellophane preferable when high transparency and aesthetic appeal are critical for consumer attraction.

Flexibility and Strength: Which Performs Better?

Cellophane offers moderate flexibility but is inherently more brittle compared to LDPE, which exhibits superior flexibility and elongation properties, making it less prone to tearing under stress. In terms of strength, LDPE outperforms cellophane due to its high tensile strength and impact resistance, essential for durable packaging applications. For environments requiring robust, flexible materials, LDPE is generally the better choice, while cellophane suits applications valuing biodegradability but with less demand on mechanical strength.

Food Packaging: Cellophane vs LDPE Suitability

Cellophane offers superior breathability and moisture resistance, making it ideal for packaging fresh produce and bakery items by preventing condensation and preserving freshness. LDPE excels in flexibility, puncture resistance, and cost-effectiveness, suitable for packaging items requiring high durability and airtight seals like frozen foods and snacks. Both materials cater to different shelf-life requirements and product types, with cellophane favored for natural, eco-friendly solutions and LDPE for longer-term preservation and versatility in food packaging.

Cost Comparison: Cellophane vs LDPE

Cellophane generally has a higher production cost than LDPE due to its natural cellulose base and complex manufacturing process. LDPE benefits from lower raw material costs and simpler polymerization techniques, making it more cost-effective for large-scale packaging. Despite higher expenses, cellophane offers eco-friendly advantages that can justify its price in sustainable packaging markets.

Recycling and Disposal Challenges

Cellophane, derived from cellulose, is biodegradable and compostable but requires industrial composting facilities for effective breakdown, posing challenges in standard recycling streams. LDPE, a petroleum-based plastic, is widely recyclable through specialized programs but often ends up in landfills due to contamination and lack of infrastructure. Both materials present disposal challenges, with cellophane's biodegradability limited by facility availability and LDPE's environmental impact reliant on recycling participation rates.

Best Use Cases: When to Choose Cellophane or LDPE

Cellophane excels in applications requiring superior breathability and a natural, biodegradable packaging option, making it ideal for fresh produce, bakery items, and gift wrapping. LDPE offers excellent moisture resistance, flexibility, and puncture resistance, which suits it well for packaging liquids, frozen foods, and heavy-duty bags. Choose Cellophane for eco-friendly, transparent wrapping and LDPE for durable, moisture-proof packaging needs.

Cellophane vs LDPE Infographic

materialdif.com

materialdif.com